Embroidery pricing is not easy.

Many print shops take on embroidery as an afterthought, then discover it’s harder than they imagined. They buy a few used embroidery heads and dive in, not realizing the complexity involved with embroidery. Other shops focus entirely on embroidery and still struggle with pricing their embroidery work.

This is a challenging topic, and we can’t tell you the exact price you should charge for your embroidery. But we can share ways to price your embroidery more effectively and profitably.

The two challenges with embroidery pricing

There are two major challenges print shops have to overcome to conquer embroidery pricing: their costs and understanding order complexity.

The first challenge to embroidery pricing is understanding your shop’s unique costs.

Shops have different costs involved with running their embroidery heads. Utilities, labor, debt, and a variety of other unique costs are typically fixed. But they’re still different between businesses. Smart pricing strategies are impossible without a firm grasp on your shop’s “Minimum Revenue Required.” To put it simply, you have to bring in enough money to keep your business running! The basic, back-of-the-envelope calculation looks like this:

Minimum Revenue Required = (Overhead $ + Labor Cost $) / Time

This isn’t a perfectly accurate calculation. But it’s powerful enough to give you insight into how much your embroidery work should net per hour! Another way to think about this: if you can sew 60 caps in an hour, but can’t sell them for the price of your shop’s overhead and labor costs, then contract embroidery might be a more profitable endeavor.

The second challenge to embroidery pricing is understanding order complexity.

What do we mean? Well, if you’ve spent time doing embroidery work, you probably have nightmares of that 30,000 stitch run with dozens of thread breaks. You’ve puzzled over bad digitizations and been humbled by terrible sew outs. Embroidery is more complex than other types of custom apparel decoration and most embroidery happens on products that are much more expensive than a simple t-shirt. This means that embroidery pricing always has an element of anticipation and artistry to it. You may not get every order right, but you must understand that complexity and difficulty should be part of your pricing model.

To put it bluntly: embroidery takes longer and costs more than you expect.

Download a free sample embroidery pricing matrix

Here’s a sample of a pricing matrix used for embroidery. Download it, use it as a template, and see if you can’t make your own embroidery pricing matrix!

Remember: you can easily price your embroidery with Printavo’s Pricing Matrix. Need help setting up your pricing? Reach out to Printavo.

Download Free Embroidery Pricing Matrix

Embroidery is not like screen printing: it’s got a speed limit

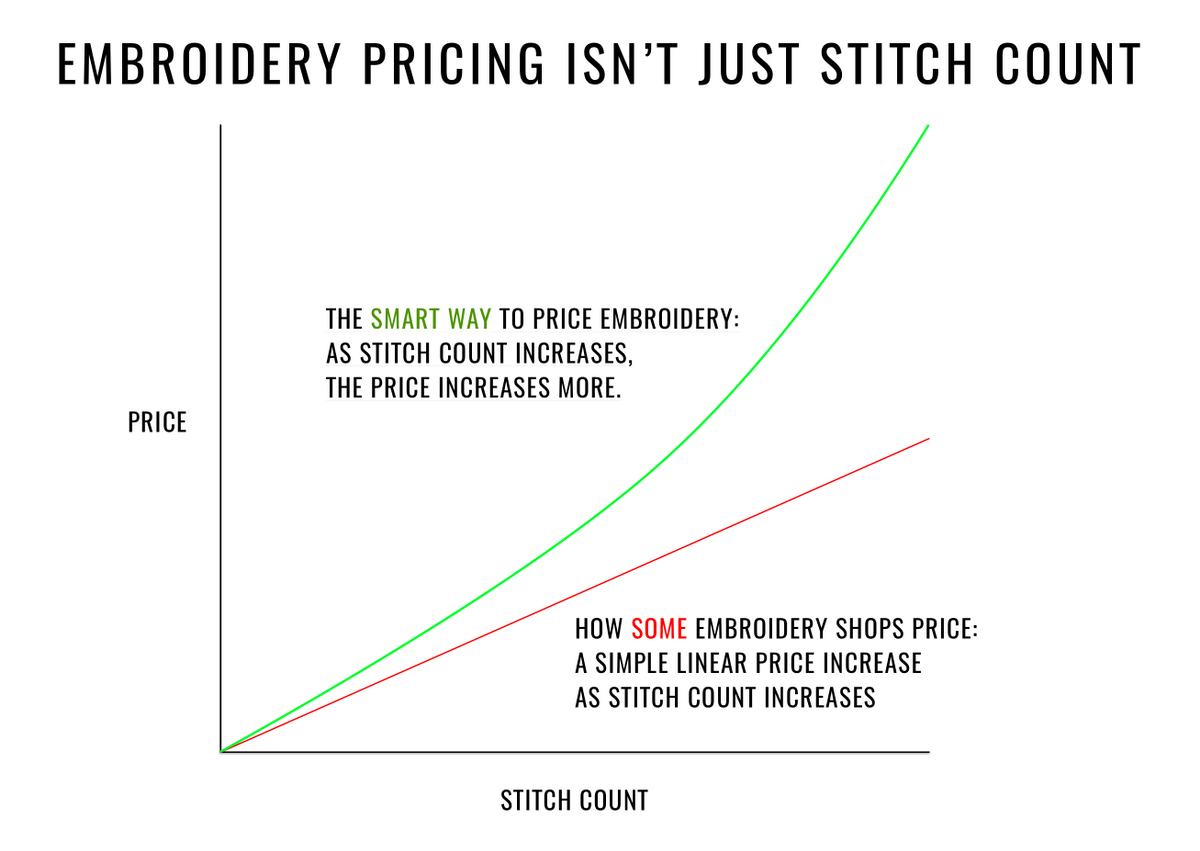

Key insight: a linear pricing model is a bad way to show your customers how more stitches impact the order. More stitches equals longer run times, more thread breaks, more machine errors. Teach customers that adding stitches greatly increases the overall complexity.

To screen printers, a 30,000 piece order is a great opportunity. Get your approvals, burn your screens, and run through your screen printing process. You can blast through 400 shirts an hour and crank out that order over a few days.

The automatic press that can print 400 shirts an hour does not exist in the world of embroidery.

Embroidery is a slow process. Each and every piece requires an immense amount of detail, focus, and precision. In screen printing, you can give that 30,000 piece order absolutely massive price breaks since you can really crank them out once you get going. In embroidery, the first product takes as much time as the last product – and just as much attention, too. There is significantly more labor involved with each embroidered piece compared to printing a t-shirt. It’s not just loading and unloading shirts!

Let’s give you some numbers to make this example clearer. It’s possible you can only produce 50 pieces an hour if you have 12 heads of embroidery running a 5,000 stitch job. Think about it. Every product needs to be:

- Hooped

- Loaded

- Sewn

What this means for your pricing is simple: there should be fewer price breaks on embroidery for quantity.

Embroidery jobs vary: each and every order is different

A lot of businesses that do embroidery give approximate prices based on stitch count. We think this is too simplistic. You have to take into account the overall complexity of the order. How much work will it actually take to successfully embroider those hats, jackets, or bags?

When you think about downtime and embroidery, think about these considerations:

- How often will you have to cut thread?

- How often will you have to change color?

- How many threads will need trimming afterward?

- How hard will the garment be to hoop?

- Do you need a special backing?

- How many sew outs will you need?

- What if you need the job re-digitized?

There is no simple formula or easy way to calculate the price you should charge for this kind of complexity and risk. Lots of things can cause hiccups along the way during embroidery jobs. Train your salespeople, specifically, to understand there should be a real premium charged for complex embroidery jobs.

What this means for your embroidery pricing is: don’t expect to have a one-size fits all pricing formula for embroidery.

Embroidered products are more expensive

Virtually any product that you embroider will be more expensive that a product you’d typically screen print on. This seems like an overbroad generalization – but it’s true! Embroidered products command a premium from consumers. Think about where you see embroidered products: official uniforms, pricey sports bags, high-end jerseys, expensive hats, luxury jackets. If you took a cross-section of the COGS (cost of goods sold) for a typical screen print shop versus an embroidery shop, we’d wager that raw goods for embroidery are more expensive than raw goods for screen printing and DTG printing.

The risk for spoilage in embroidery is pretty high. You’re sewing on things like costly North Face jackets. What if you’re just embroidering for basically a few pennies and ruin a few of those jackets? There goes your profit!

You have to charge more for embroidery because your COGS is higher.

Don’t be afraid of this! Customers are typically blown away by the finished product. They’re willing to pay a premium for custom embroidery. You can raise your prices for embroidery just like you can for screen printing. And to tell the truth, you probably have to if you really account for all of the costs and risks involved.

Embroidery should always include setup and digitization fees – even if you hide them

Want to offer “free digitizing”?

Fine!

But you should sell 50 garments minimum. And keep artwork simple. And consider rolling that digitizing fee into your pricing anyway.

Setup fees are another sticking point. You really do need to charge for staging the garments, figuring out how to hoop them, and generally managing the entire procurement and embroidery process from end-to-end. There’s a cost associated with all of that time and effort in your shop. Charge appropriately.

Embroidery pricing should almost always include digitization and setup fees. If you want to hide those fees from the customer, add them to your prices.

There’s a brilliant mental trick here: you can just remove digitization and setup fees as line items on your invoices. Roll them into each piece and it can become pennies on the dollar instead of a big-ticket item your customer wants to negotiate over.

Only do embroidery orders that actually work for you

Incentivize your customers to cater their orders to your business. What does this mean, practically? If you have 6 heads of embroidery, give a small discount on quantities that are multiples of 6. If you only have one head of embroidery that can do custom names, charge a premium for that and steer customers toward something simpler.

There is no reason to put a burden on your business because you’ve said yes to things you cannot do well. There’s a cost associated with that kind of challenge. Unless you’re hungry to do research and develop on each embroidery order you take, counsel your customers to choose techniques, styles, and even garments that you know you can embroider.

Conclusion: 5 things to keep in mind when you price embroidery

Don’t fall into the stitch count trap.

Embroidery pricing isn’t so complex when you keep these simple things in mind:

- Set digitizing and setup fees based on complexity. Have Easy, Medium, and Hard fees.

- Increase prices as stitch count goes up. For example, $5 for 5,000 stitches goes up to $6.50 for 6,000 stitches…and so on.

- Keep quantity and price break discounts low. In embroidery, more pieces equals more problems.

- Charge a premium for premium products. Compensate for hooping challenges and risk. Use an Easy, Medium, Hard pricing tier as well.

- Use COGS and raw good cost in your pricing. Markup your garments and products appropriately. Use a higher markup (50% or more) than you would for screen printing.

This isn’t as complicated as it seems – just break it down into an ala carte menu for customers. You want a North Face jacket with 6,000 stitches? Markup the jacket appropriately, offer some more affordable options, then decide whether it’s an Easy, Medium, or Hard setup and digitization fee. Negotiate the correct number of jackets, teach the customer about the risk, and see if they’re still on-board with embroidery.

Remember: you can easily price your embroidery with Printavo’s Pricing Matrix. Need help setting up your pricing? Reach out to Printavo.

Last updated August 2020.

0 Comments