Shortages and supply crunches have plagued a lot of industries since the pandemic upended global trade.

Look at the price of lumber, for instance:

A commodity that barely ever passed above $500 exploded to more than $1500 in less than a year.

Then it fell right back down, even faster than it went up.

If you’re tired of seeing charts that behave like this, you’re probably not alone.

Shortages have hit the garment supply chain hard

“Out of sight, out of mind” is the attitude when things work – but the breakdown of the supply chain is apparent to everyone struggling to order goods now.

Just look at what Kimarie from Clockwork Enterprises posted:

Dozens replied with the same problem.

It’s not just you. It’s real, and it comes down to one thing: the shipping container.

I wanted to understand why there’s a shortage in apparel.

It turns out the reason is pretty simple: a whole bunch of shipping containers.

But since that doesn’t make sense on its own, let’s dive a little deeper.

Where’s the cotton grown?

It all starts with cotton.

The history of cotton is fascinating and worth its own newsletter, but it’s now a global trade that’s concentrated in China, India, the US and Brazil. China has the lion’s share of the world’s cotton production.

My first thought was that coronavirus must have impacted the cotton harvests throughout the world. This wasn’t the reality, however.

In 2020, cotton production was definitely lower than 2019. But it didn’t matter. The forecasted supply of cotton was the highest in 6 years because of Chinese government policies.

So if the supply of cotton isn’t the issue, what the heck is going on?

The factories aren’t where the customers are

The global textile industry is wildly concentrated in China, with more than 50% of the world’s textile output originating there.

While the textile trade captures more than just t-shirts and other products used for custom apparel, it’s a great approximation for the center of the supply chain.

The factories, tools, laborers, and knowledge required to execute garment manufacturing at scale reside primarily in China.

But that’s not where the customers live: the EU and US account for an astonishing $98B of textile imports every year.

An even more astonishing caveat to this long chain of goods?

It’s not unrealistic to imagine a supply chain that involves 4 countries and some overseas travel:

- The cotton is grown in one country

- Then shipped to another where it’s processed into fabric

- Then shipped to another to be made into garments

- Then shipped to you for printing

The common thread there isn’t even the cotton at this point. It’s the shipping. We all need shipping.

We need a bigger boat? Kind of…

Remember that goofy Suez Canal incident from a few months ago, when a giant cargo ship plugged up the world’s bottleneck and basically stuck a pin in global trade for a few weeks?

Well, there’s been a less noticeable…but more noxious…version of that brewing in the cargo markets for months.

All of those shipping containers that get shipped around…have to get shipped back.

For months, ports in the United States weren’t sending back empty shipping containers (for every 100 received, they were returning something like 40).

This created a massive bottleneck where there simply weren’t enough shipping containers when the global supply chain needed to switch back on.

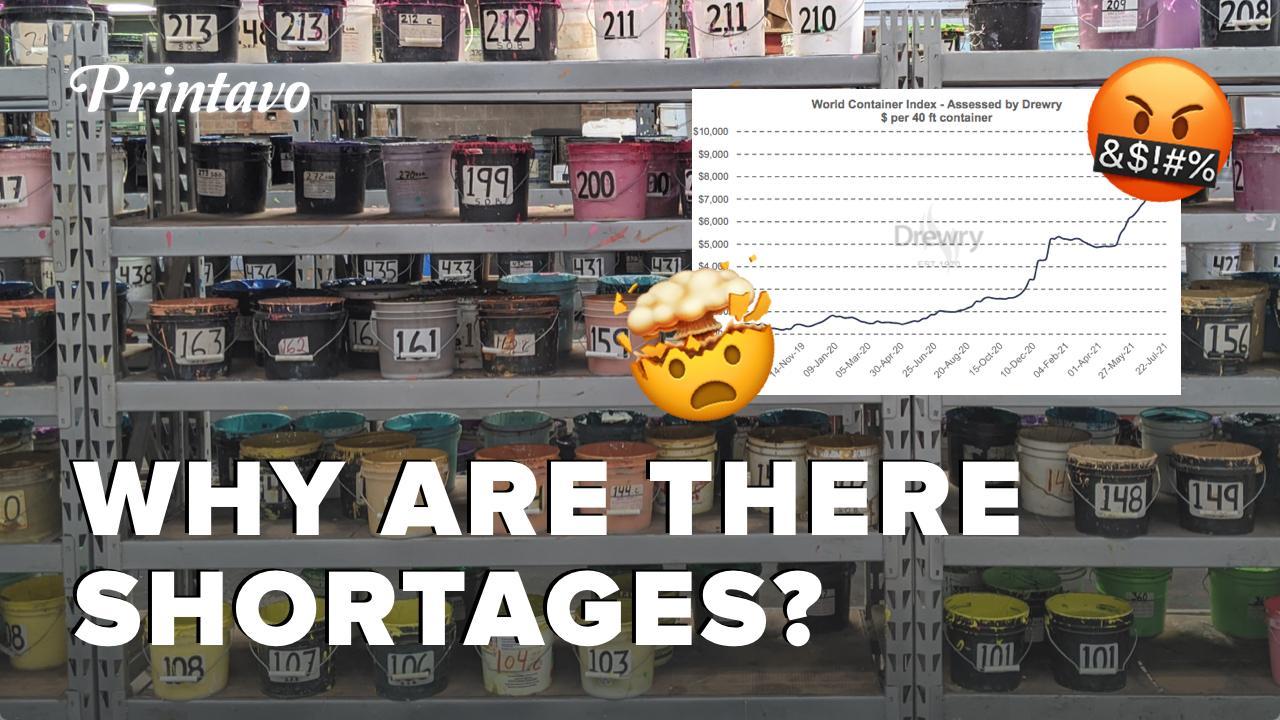

So, of course, the price of shipping containers (shown above) is another one of these annoying hockey-stick shaped graphs.

Will this last?

It’s definitely possible that this disruption lasts longer than anticipated.

But there’s reason to be hopeful.

In the “it’s going to last” camp, there are several factors:

- 42% of North American container freight flows through three ports: New York, Long Beach and Los Angeles. There’s a lot of congestion (read: traffic) at all three ports right now.

- Demand for shipping is really high. Like, all-time high. It’s tempered somewhat, but the return to pre-pandemic levels (and then some) has happened.

- There are other clouds on the horizon. If you’re bearish, you’ve probable got a whole list of reasons (inflation, COVID fears, other supply disruptions).

For the “it’s not going to last” team, there are some good points:

- High container prices are a temporary response. A few companies can send prices sky-high, but they can’t (and won’t be able to) do it forever.

- The flow of containers and ships is resuming. The shortfall of containers and equipment will abate, because orders for ships are also at an all-time high and will eventually catch up with demand.

- Domestic operators may start to invest. While operators have begun cut-and-sew operations in the US, it’s not hard to imagine further investment in domestic facilities if shipping containers stay at $9,000.

So what should you do?

Ultimately, you have to roll with the punches.

What can shops really do to get ahead of the curve? Change how they react to the conditions at hand. Here’s a few simple tips:

- Find alternatives to your most common garments. Whether you have one, two, or seven substitutes for simple things like black tees – be ready to find alternatives and buy when you can.

- Have a clear substitution policy in place. Be ready to substitute, and have a written (and communicated) policy in place for it.

- Communicate proactively about shortages. Let customers know that you’re dealing with shortages too.

- Extend your lead times. No one wants a slower turnaround, but extending your lead time adds a cushion you need.

- Budget extra time for ordering. You’re going to need to spend more time looking for and procuring garments than you did, so plan accordingly.

- Make an infographic or sign. Signage and simple messaging go a long way, and just letting everyone know what’s going on can help. Here’s our infographic.

- Raise your prices. It’s always acceptable to raise your prices to adapt to challenging conditions. If you haven’t yet, now is the time.

This is an excerpt from The Weekly, Printavo’s newsletter. It’s the easiest way to get educated in the print industry without paying a dime, delivered to your inbox.

0 Comments