Your screen printing shop is hiding something.

It’s not as productive (or profitable!) as it could be.

How do I know?

I talk with owners like you every day, and I see & hear the struggles they face with managing the complicated screen printing process.

There’s no magic formula for making your print shop a success. But the bottom line is that standardizing and simplifying your print shop’s process is something that very few owners take seriously.

You’ll invest in the highest-quality equipment, hire experienced screen printers, diligently purchase the best inks and pay a premium for fabrics that produce the best results. So why aren’t you investing your time into perfecting your processes?

Here’s the 8 key things that I’ve seen successful garment decoration businesses do to improve their shop’s efficiency:

- Constantly improve, without fear.

- Communicate.

- Refine & improve, proactively.

- Eliminate physical & mental clutter.

- Engage the entire team.

- Keep tools ready.

- Standardize production steps & vocabulary.

- Work backwards to make plans.

1. Constantly improve, without fear.

Toyota’s massive Georgetown, Kentucky production facility. Your shop isn’t this complicated!

Don’t be afraid to fail. Be afraid to become stale.

Everyone knows Toyota.

Toyota makes cars.

Making a car is among the most complicated production processes. Parts come from all over the world, the actual product is large and requires substantial real estate just to house, designing it is complicated, and hundreds (if not thousands) of people are involved in each individual product – just to name a few complications!

But year after year, Toyota makes cars that last longer and perform better.

They have a sterling reputation as the most reliable automaker in the world.

So what can Toyota teach print shop owners?

Toyota made improving their process a core component of their production process.

It’s called the Toyota Production System. It’s simple, easy to understand and fits on a single printed page. The Camry isn’t their most valuable product. TPS is.

The Toyota Production System is Toyota’s secret sauce.

Simplifying your production by continually improving it is the secret sauce in the garment decoration business.

Are there too many steps in your process? Is it simply too complicated?

See how many parts you can remove.

Have you really experimented with better inks that cure faster? Different consumables that can be shipped faster? A better work order form that clarifies everything for your workers? Arranging your presses so workers can move freely throughout your space?

Don’t be afraid to fail. Be afraid to become stale. (It’s such good advice that I have to tell you twice!)

Small experiments can determine whether your process is as refined as it should be. You don’t need to rip everything up and start over – big changes start small.

If something isn’t working in your process, then stop and get your process right.

Don’t keep the line moving just because you feel like you have to. In the long-term, you’re only hurting yourself if you’re not developing and revising your process.

2. Communication in your print shop

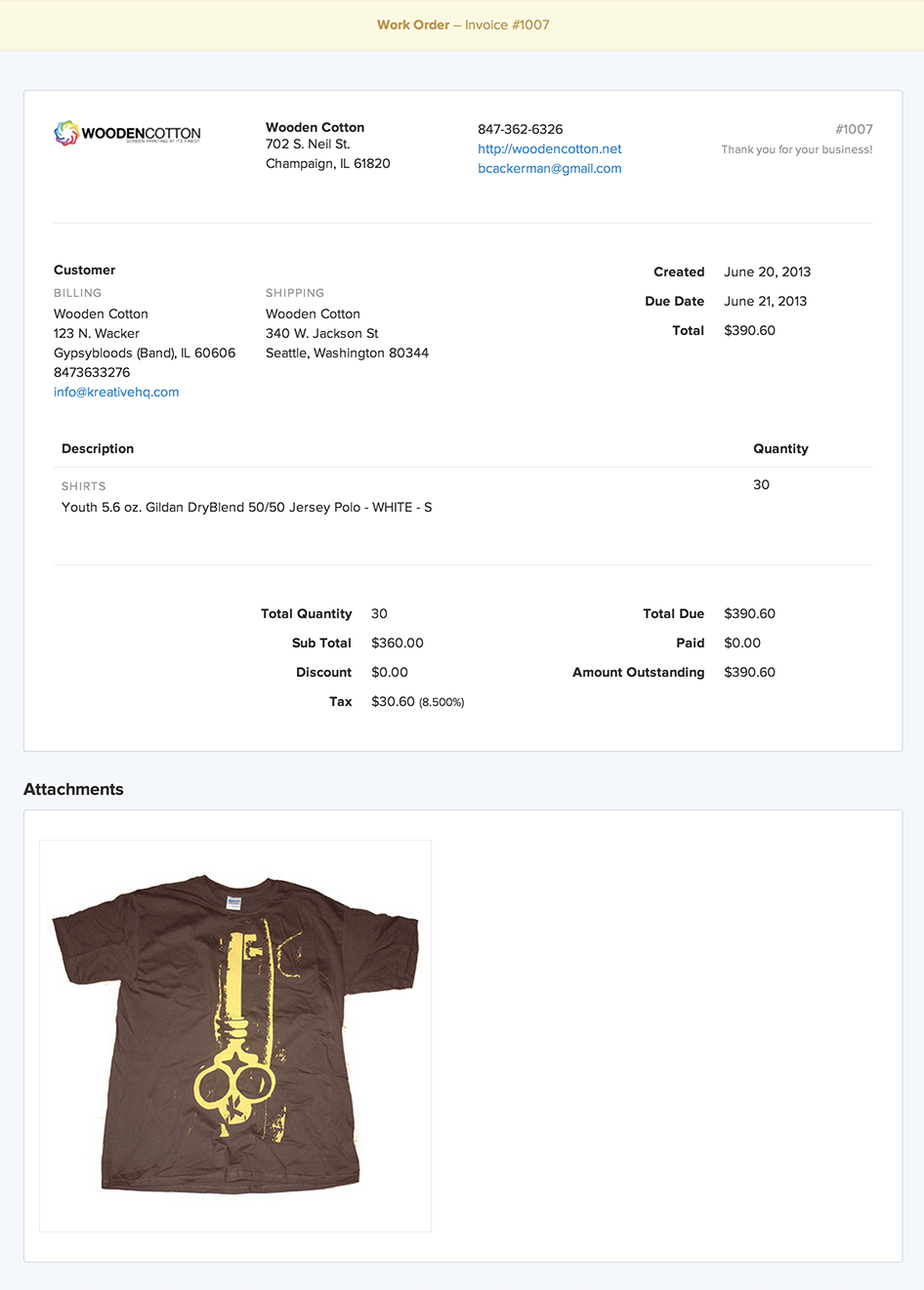

An example Printavo work order: you’ll add more details than what you see here!

The first step to improving communication in your shop? The work order.

How many times have you put in a work order – only to spend a lot of time answering questions about the order?

If that sounds familiar, then it’s time to dig into your work order process and refine it.

Work orders aren’t just instructions.

Work orders are how you communicate about the job.

A print shop’s work order is really a communication tool. It should clarify important details, like:

- The specific Pantone colors to be printed

- Exactly which inks to use

- How the print will be completed

- Which worker is assigned to the job

- When the job is due to be completed – and when the customer expects it

- Unique or challenging requirements

- What the finished product should look like

- Sizes & quantities

- All necessary details to finish the job – not just get most of the way through it

You know how to communicate with your customers. The work order is a bridge between your customer, yourself and your printers.

If you spend more time creating great work orders, you’ll see a payoff: your workers won’t have to chase you down to ask you questions.

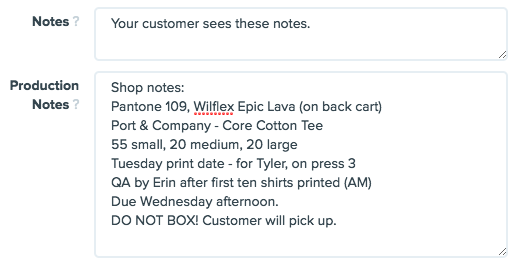

Entering detailed work order notes in Printavo. Only the shop sees Printavo Production Notes!

Questions are great! However, great work orders keep the work moving without a game of twenty questions every time you start a new job.

Write your work orders like your shop will be forced to print the job without you.

Communication starts with customers, flows to you and exits through the work order – good work orders reduce errors, misprints and production problems before they start.

3. Refine & improve your process, continuously.

Ready for another day of production: the Barrel Maker Printing shop in Buffalo Grove, IL.

There’s a simple way to start improving your process:

Plan & setup tomorrow’s process today.

Time spent setting up tomorrow’s work is an investment.

Aim to start the day with as little input as possible! This means getting everything your printers will need for tomorrow’s jobs ready:

- Inks

- Shirts & apparel

- Screens

- Tools

- Work stations

- Work orders

As you develop your strategy for the next day, you’ll begin to see where your process broke down today. Maybe the process didn’t break down, but something small went wrong. You can anticipate that issue & set up a solution instead of simply hoping it doesn’t happen again.

Can you spend time on registration for tomorrow’s job, today?

Can you line up jobs in their proper order?

How about mixing inks or cleaning squeegees?

Does tomorrow’s job call for setting up specific pallets?

Preparation is a shortcut for improving your process.

Good preparation acts like a “daily audit” – you’ll see where you’ve been and where you’re going. Then, you’ll be able to make small adjustments a natural part of your daily printing process.

4. Eliminate physical & mental clutter

Everything in its right place: inks labeled and organized neatly.

“A clean house is a sign of a wasted life.”

That may be true, but a clean shop is a sign of an efficient & thoughtful process for maintaining productivity.

The screen printing process is messy. Ink is challenging to clean up. Dust gathers quickly on the production floor. Product seems to accumulate in ever-larger piles as the day goes on.

Eliminating clutter isn’t just a housekeeping task – it’s vital to keeping your production numbers high.

Try these tips to invest in decluttering:

- Start small: if you need to walk around something that’s in the way, can it be moved?

- Utilize shelving & storage: relocate “occasional use” items to a place where they’re still accessible but out of the production zone.

- Create priority zones: keep everyday items in one zone, occasional use items in another zone, and rarely used items as far from the production process as possible.

- Audit what you use: are you keeping an extra screen printing press, a bunch of ink, or wholesale apparel product around because you think you might use it? Know what is and isn’t useful for each day, and prioritize the everyday use items.

- Ask your team what annoys them: the people who work in your shop know what’s clutter and what isn’t. Empower them to have a voice about their environment! What may seem like clutter to you could be something they use every day.

Simple, scheduled tasks like keeping inks organized by color, utilizing large & legible labels for everything and keeping a schedule for cleaning squeegees & flood bars will improve productivity in the long run.

But what about mental clutter?

This topic is more complicated.

You can’t control what’s happening in your workers’ lives, or what issues they’ll bring to the shop with them every day – what you can do is set consistent expectations, communicate about each job clearly and refine your shop’s process so that there’s no guessing about what happens in a given situation.

5. Engage the entire team

Erin Moore of Barrel Maker Printing demonstrating how to think about using a flood bar.

When everyone pitches in, print jobs get done faster.

Level out the workload by identifying when your workers are idle and (more importantly) when they’re overworked during your process.

One solution I’ve seen involves cross-training workers: utilize your catcher to set up jobs.

If your catcher is idle, they can begin anticipating tomorrow’s work and planning for those jobs.

The more hands you have working to accomplish jobs, the faster your production can move.

Taking an honest account of where your employees are idle (or overworked) is key to improving productivity.

6. Keep tools ready

Squeegees in their final destination for the day. After a quick wash, they’ll be ready for tomorrow’s jobs.

How you manage your tools is an indicator of how well your print shop is managed.

Are tools scattered here and there?

Are your workers forced to run across the shop to grab something several times a day?

Are you replacing tools that have been broken or lost?

None of your workers should struggle to find the tools they need. So what should you do?

There’s actually an easy process for keeping tools ready:

- Create a standard set of tools for each step of your process, then get multiple sets of them.

- Keep tools located in one area at the end of the day. This way everyone knows “where the tools are,” regardless of their role in the shop.

- Utilize push carts so tools are easy to transport and access.

- Schedule a regular “deep clean” to audit your tools.

- Label toolkits for each employee so they’re ultimately accountable for them.

Curating toolkits for each printing role keeps your shop organized & on-tasks: if they have their kit, they can do their work.

Even if a printer is assigned to an unfamiliar press area, they should be able to count on having the same tools ready for them.

If your employees fail because of problems with their tools, it’s probably your fault.

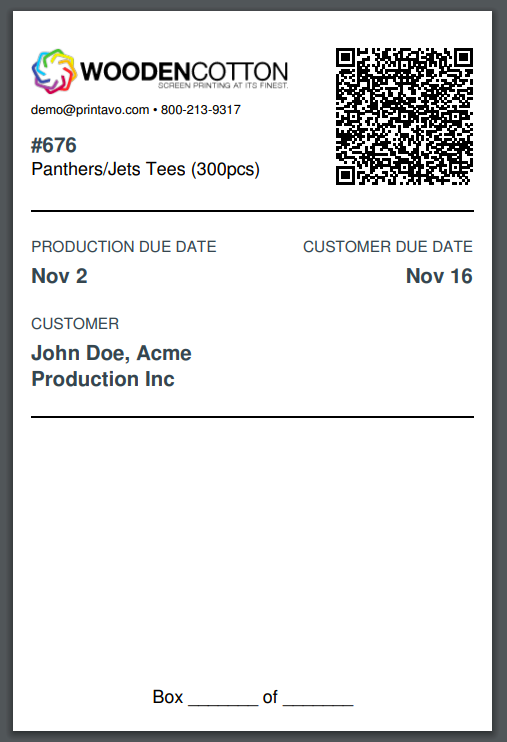

7. Standardize your printing process steps & language

Labeling boxes in a standardized way is an easily implemented win.

In a truly productive shop, you can switch out one worker for another with minimal disruption.

Why?

Because everyone knows how to do things your way.

The first step? Draw a flowchart for every step your shop’s process. A tool like Draw.io can help you visualize your process and find problem areas – and show everyone your exact workflow.

Another easy win that every shop should implement is standardized box label placement.

If you place your box labels on the outside upper left-hand corner, every label is easy to find.

No one has to guess how boxes were labeled for this order – or rearrange boxes just to mark them as completed for that order.

Over the course of a year’s orders, you’re saving hours and hours of time spent looking for labels and reorganizing boxes.

The next step is to implement a standardized shop vocabulary.

While experienced printers and shop owners all speak the same language and use the same words to refer to equipment, inks and other elements of screen printing & custom printing – you can create your own language to refer to processes in your shop.

Spend half an hour with your crew identifying the terms they already use – and make them standard.

It doesn’t have to be complex language or difficult to implement – just be consistent about the terms you use!

For example:

“Full Front location”: a 12” wide image, printed 3” from the collar.

“Black Shop Tee”: a Gildan G2000.

“In-hands day”: when the customer wants the order.

There are many more examples that you’ll be able to think of. The point is to have easy-to-understand terms for each specific part of your printing process.

Standardized language will make your team’s communication quick and consistent.

8. Work backwards to make plans

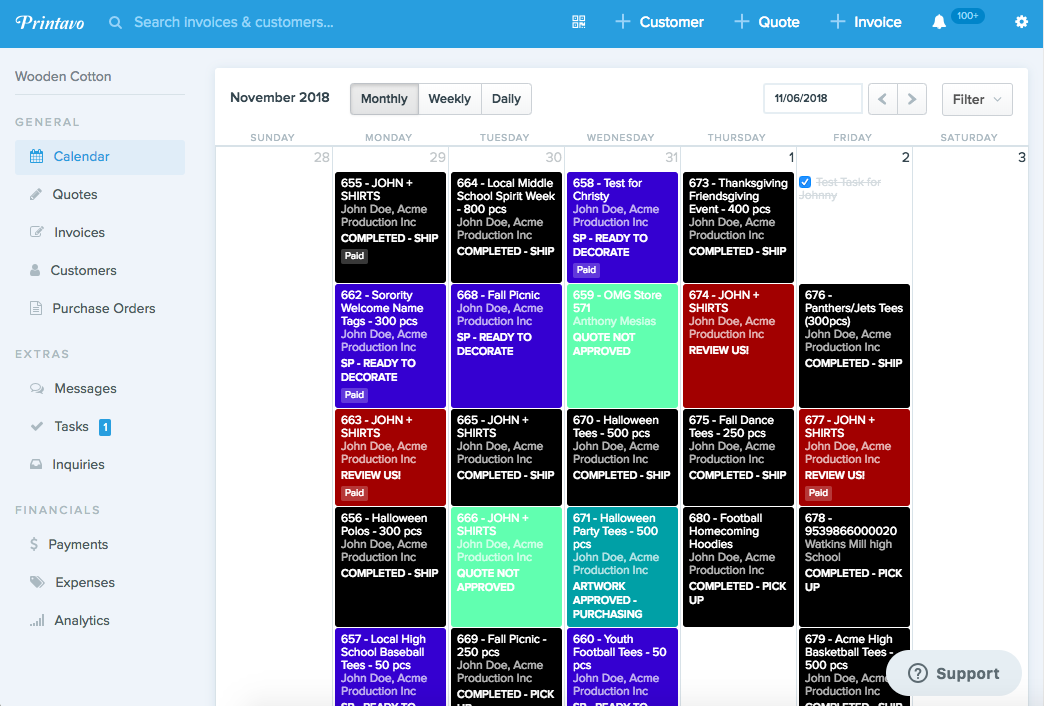

A shop calendar makes planning simple.

Do you know how much time each part of your process takes?

The odds are good that you have some rough estimate: maybe art approval takes a couple of days, burning your screens an hour or two, setting up your press another half hour.

You don’t need to time every action on your shop floor with a stopwatch…you do need to know where to spend time improving your process.

Ultimately, what really matters is when your customers get their goods.

Start there, then work backwards to develop a strategy for planning. Here’s what I mean:

- The customer wants their order on the 10th.

- That means everything should be ready to ship on the 9th.

- Therefore, printing needs to happen on the 8th.

- So your screens & process need to be set up on the 7th.

- Art needs to be approved on the 6th.

- Then goods need to be ordered & down-payment collected on the 5th.

Your shop won’t follow that script exactly, but it’s a good template for auditing your process. You’ve got to know your shop’s timetable to execute jobs on schedule.

Where do you typically encounter problems?

What’s caused delays in the past?

Is the customer flexible on the ship date – or maybe your supplier isn’t totally reliable?

Things will go wrong. Even the best laid plans go awry.

How you anticipate and plan for those breakdowns in the complicated print shop process is how you can succeed.

Start at the end and work backwards to identify the best process for your shop.

Shoot bullets, not cannonballs

Barrel Maker Printing: no stranger to changing their process. That’s how they’ve been so successful!

Changing your shop’s process is scary. So don’t shoot a cannonball into your process and blow everything up. Shoot a tiny bullet at a small problem and learn from the results.

It’s not easy to do things differently. We want to stick with what we know, even if it isn’t working well!

I challenge you to go back to your shop and implement just one of the changes I’ve suggested:

- Constantly improve, without fear.

- Communicate.

- Refine & improve, proactively.

- Eliminate physical & mental clutter.

- Engage the entire team.

- Keep tools ready.

- Standardize production steps & vocabulary.

- Work backwards to make plans.

Try it. Just one! See what happens & let me know what you learn.

It’s ok to be afraid.

It’s not ok to just stagnate and wonder what could have happened if you’d tried a slightly different way.

There’s nothing but upside.

Why I built Printavo

I started building Printavo in 2012 because I love screen printing, and I realized that custom print businesses needed help improving their process.

I couldn’t keep track of my jobs or send out invoices, much less get art approval, without a lengthy process that kept me from doing the printing I wanted to do.

I wanted to make a lightweight, simple tool that could be customized for each and every print shop. I built it around a calendar, because that’s where real success starts: getting your orders to the customer on time, every time.

Printavo is that tool – but it’s up to you to refine the process that works for your print shop.

0 Comments