Creating a culture of accountability

Your biggest customer calls:

“I can’t use any of these shirts. They’re all wrong. You’re going to replace them or I’m going to find another shop!”

You hang up the phone. Your blood pressure is through the roof. What happened? How did you not find out about it before the customer did?

This story hits home with far too many screen printing shops.

If this has happened to your shop, what happened next? Did you:

- Get angry. Slam the phone down and throw an expletive-laden tantrum in front of your staff

- Assign blame. Call an emergency meeting with all of your department heads and try to figure out who “didn’t do their job”

- Try to fix the system that broke down. Look at yourself as the primary source of accountability and try to understand what led to letting this issue get to the customer

If you said the last one, you’re probably lying – or deluding yourself. The overwhelming majority of print shop owners and managers are prone to the first two reactions: anger and blame-seeking. It’s human instinct!

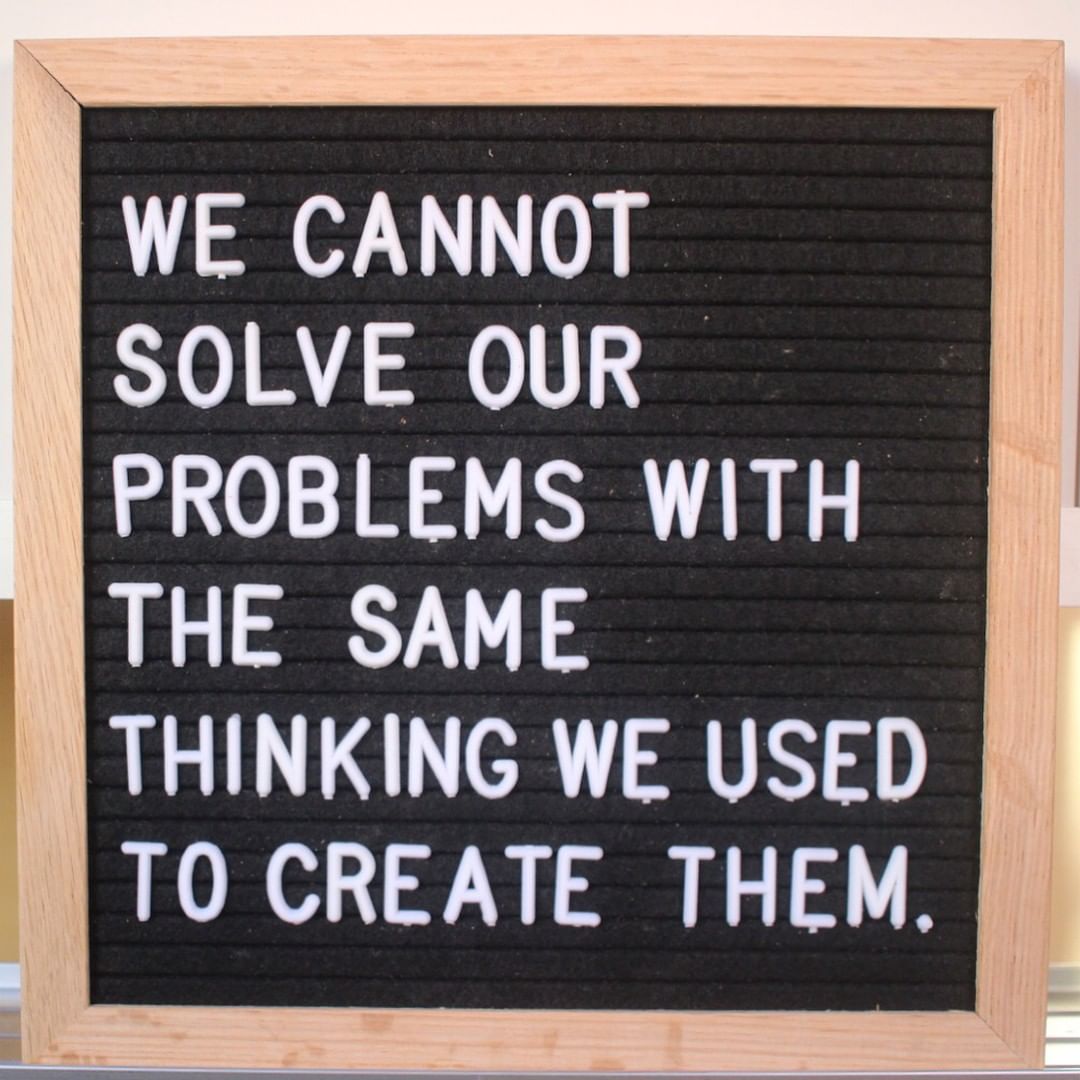

Instead of focusing on the single issue at hand, the smartest leaders will look at the mistake as part of a system. If you leave the system in place that created the problem, there is a 100% chance that a similar mistake will happen again.

This is where accountability comes into the picture. Accountability is about more than assigning blame or rooting out what caused mistakes. Though one team member may be responsible for a mistake, all parts of the company are accountable for mistakes. Since your brand and bottom line suffer when mistakes happen, your entire business is ultimately accountable for what it manufactures.

Teaching your team accountability requires two crucial attitudes:

- Willingness to develop systems for production that encourage accountability across your entire team.

- Accepting that your role as a manager or owner is to create systems for accountability.

As your team’s leader, you create a culture of accountability with your actions and habits.

Accountability starts from the top of the company

You have to talk the talk and walk the walk, day in and day out. This is basic leadership: take the wins, own the losses – consistently.

If you’re the first person to take accountability for a product error made by your team, you demonstrate integrity. This means you take credit for things that go really well – but you fearlessly tackle errors when they do occur. But accountability means taking it a step further: you don’t just fix that error, you fix the process that created the error.

Ownership and accountability means caring about process as much as you care about outcome.

It doesn’t mean you never interrogate someone that made a mistake. It doesn’t mean that everyone in your shop just funnels blame onto you. It means you find the source of the problem and create systems to prevent that same problem from recurring.

Setting a high bar for professional accountability starts with constant improvement. When that big client hangs up the phone, you don’t get mad or start blaming people. You find a way to improve your printing process.

True accountability is a constant force and does not play favorites

Yes, it’s inevitable that you will like some employees more than others. That, too, is human nature. You can’t control that. What you can control is the system that holds every employee to account. You don’t want employees in your printing department held to different levels of accountability for a job than your screen department or your quality assurance department.

By keeping your employees universally accountable no matter how much you like them or how valuable they are, you create an open dialogue around process improvement.

You want a culture where openness about the process and candid truth-telling about production is natural. Employees should feel comfortable “stopping the line” if problems happen, and shouldn’t feel like they need to hide from or be afraid of consequences if your production system breaks down.

You have to remain vigilant in your leadership and accountability. To develop accountability across departments, keep your communication clear and your expectations out in the open. Have concrete goals around spoilage and errors. Develop a documented process for mistakes that isn’t “getting in trouble” but is instead about “improving our business.” Revise and update your strategy for accountability early and often – at least every business quarter.

Accountability is not assigned, it is accepted

You do not tell someone they are accountable. You give them the tools they need to be accountable and successful, then they accept accountability.

Working to empower people to be accountable requires two strong actions on your part:

- Clear written expectations about their specific responsibilities.

- Frequent discussions about whether they have everything they need to complete their role in the production process.

You can structure this process with two very simple questions. The first is this: “What is something that went wrong recently?” The second piggybacks off the first: “What would you need to solve that problem in the future?” The people on your production floor can answer questions about process faster than you can – because they live with your process every day.

You accomplish accountability when your employees are comfortable showing you small gaps in their knowledge or your process that they’ve observed. When an employee plays a role in improving your business, they feel pride and a sense of ownership.

Autonomous, accountable employees naturally seek to improve production systems. Once an employee accepts accountability, they become invested in the outcome and contribute their unique knowledge to resolving problems.

Accountability is solutions-oriented, not problems-oriented

Screen printing photo by @behaviorringmaster

A team of unaccountable screen printers will fixate on problems and be timid about learning – since learning is risky and requires making mistakes. They are totally fixated on problems and do not try to find solutions. They are avoidant, stuck in their ways, and afraid of punishment. They do not have the right resources to solve their problems and are quick to shift blame to someone else if something goes wrong. They will say things like:

- I told you that would happen.

- Well, I wasn’t trained to do that.

- That’s not my problem.

- If the boss finds out about that problem, we are so screwed.

A team of truly accountable screen printing professionals will recognize mistakes as learning opportunities and move toward creating solutions. They are not fixated on problems, but are oriented toward finding solutions. They are creative, curious, and armed with the resources they need to stop and solve problems as they arise. Accountable teams say things like:

- I didn’t know that would happen, but I want to find out why it did and how to prevent it.

- I wasn’t trained to do that, but I could learn – or find out who can help me.

- That isn’t my problem now – but it could be, so I should learn how to help.

- I want the boss to know about this problem so we can find a way to prevent it.

For a team with accountability, tackling challenges is fun. For a team without accountability, a problem causes complete paralysis. An unaccountable team will literally try to hide production mistakes (which is basically the worst thing that can happen).

When you create clear processes for handling problems and dealing with issues, as well as solid documentation systems focused on solutions instead of assigning blame, you will avoid the dreaded phrases “I told you so,” “I didn’t know,” and “That isn’t my problem.”

Structured accountability: constant review and revision

I ask a lot of print shops that I visit about when they last did employee check-ins.

Too often, there’s a stammering answer like, “Uh, last year. We’ve been too busy to stop everything and talk.” That’s wrong.

It’s your job to provide the space and time to optimize your operations. You can use weekly or bi-weekly check-ins to have a structured conversation about how well your shop is operating.

- Ask about worker concerns.

- Find problem areas and gaps in your systems.

- Provide support.

- Go to the source and find out the problem.

Does your job description hold anyone else accountable beyond you? (I’m guessing not!) Checking your own quality of leadership with regular reviews and discussions keeps development and learning on your mind. If you’re constantly improving and always on the lookout for ways to become better, you’re in the right mindset.

Now that we have begun laying the framework for accountability in your print shop, you can start fine-tuning the specifics you’ll need from each department.

In the next article

This is part 1 of an ongoing series written from my knowledge and experience running large screen printing shops for high-volume clients with demanding turnaround times. It’s called Managing Screen Printers.

Next time, I’ll dive in and discuss stop-gaps and concrete processes to create safety nets for your printers. You’ll spot and fix mistakes as they occur, and create systems to help you do this easily.

Stay tuned and keep laying down that ink!

0 Comments