CTS (computer-to-screen) or DTS (direct-to-screen) imaging systems cost between $30,000 and $80,000 USD, so they’re a major investment for any screen printing shop.

Our CTS calculator shows some amazing data. If your screen print shop makes just a couple dozen screens per day, you can save around $5,000 a month in materials and labor costs with a CTS machine.

Better yet, it frees up press time. A screen print shop can prevent nearly 40 hours a month in wasted time on press with a CTS machine. That’s $90,000 in opportunity per month – if you can print just 300 shirts an hour at $5 per shirt.

What would that screen print shop look like? Here’s a guess:

- They’d image 36 screens every day

- They work 8 hours a day, 20 days a month

- They average 6 screens per job

- They average 10 minutes to set up a screen on press

While there are a lot of ways to generate more revenue (like making more sales with online stores), increasing your throughput is the only way to scale up for larger jobs that actually grow your business.

Key insight

Automating the screen room is one of the only ways a screen print shop can invest money and yield almost immediate improvements in efficiency, setup time, turnaround speed, and cost.

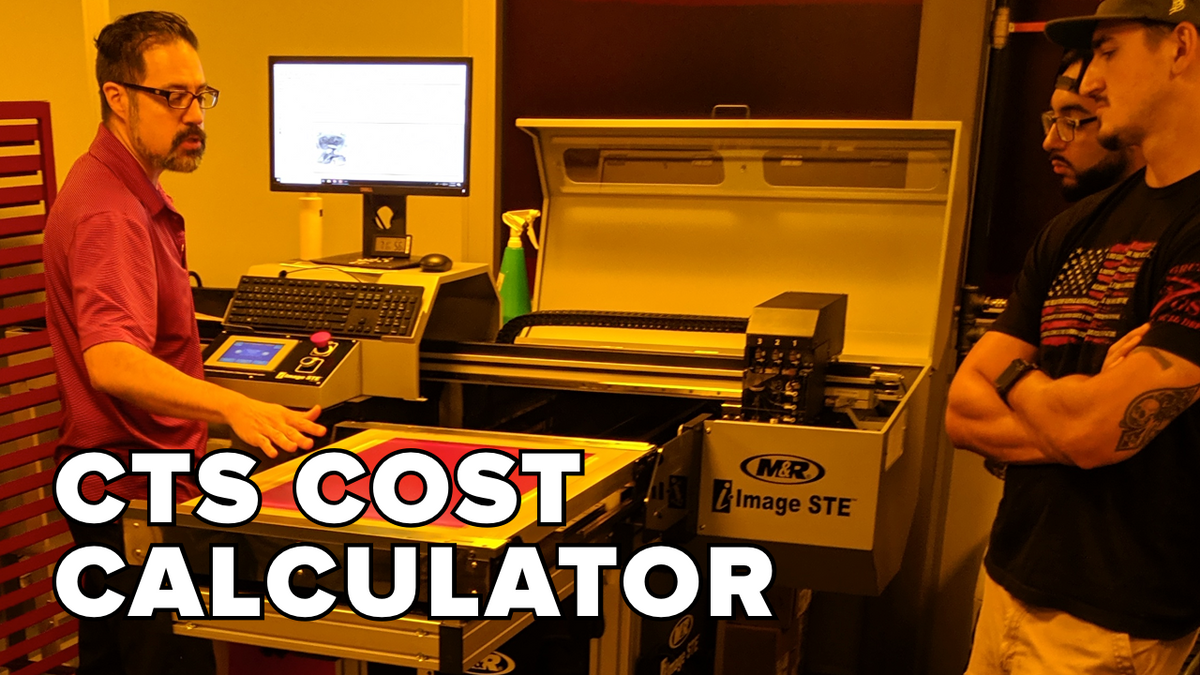

Why CTS is “The Hidden Gem” – With Lon Winters from Graphic Elephants

Before you buy your next screen printing press – watch this video about screen printing’s hidden gem! “If you’ve got enough volume to automate the screen printing process, you’ve got enough volume to automate the screen making process,” Graphic Elephants’ Lon Winters explains. Going from film outputs and your trusted Epson inkjet printer is a big step – so why is computer-to-screen technology such a hidden gem? “Basically, automating a few things ‘over in the corner’ isn’t as exciting as a new press,” says Matt Marcotte from Printavo.

“If you’re doing just 25 screens a day, it’s still worth it,” adds Lon. CTS manufacturers are conservative with their estimates about the return-on-investment for their machines. “Aggressively forward-thinking shop owners can make sense of [computer-to-screen] if they buy into the intangible benefits.” It’s hard enough to tell shop owners that their registration times will likely be cut in half – they just don’t believe it. It’s another ballgame to explain that a modest $35,000 machine could get a return-on-investment faster than virtually any other piece of screen printing equipment.

CTS machines let screen print shops print more jobs. Lon urges shops to think about the bigger picture than how fast their press can print shirts: “We’re still stuck with how fast the press goes round and round. It was all about 900 pieces an hour on the press. Well that doesn’t matter when your runs are 6 pieces on average!” Getting more jobs through your shop means more revenue and more profit – and CTS setups are the simplest way to be able to print more individual jobs.

“If you can cut your setup time, that means if your average runs are 100 pieces and you expect 10 per day – you only need to find a few minutes to be able to get 11 jobs out. Then it easily becomes 12 jobs. So if you start managing to the number of jobs instead of the number of pieces, your business can grow,” Lon explains.

Lon, Matt, and Bruce from Printavo dive further into exactly how to think about CTS, whether lasers will take over the computer-to-screen game, wax vs. ink machines, and even what “ST” stands for in M&R’s i-Image ST in this episode of the PrintHustlers Podcast.

What is computer-to-screen (CTS)?

“Computer-to-screen” (DTS) and “direct-to-screen” (DTS) are two terms to describe the same concept in screen printing. People often use the two labels interchangeably, but for our purposes we’ll call it computer-to-screen or CTS.

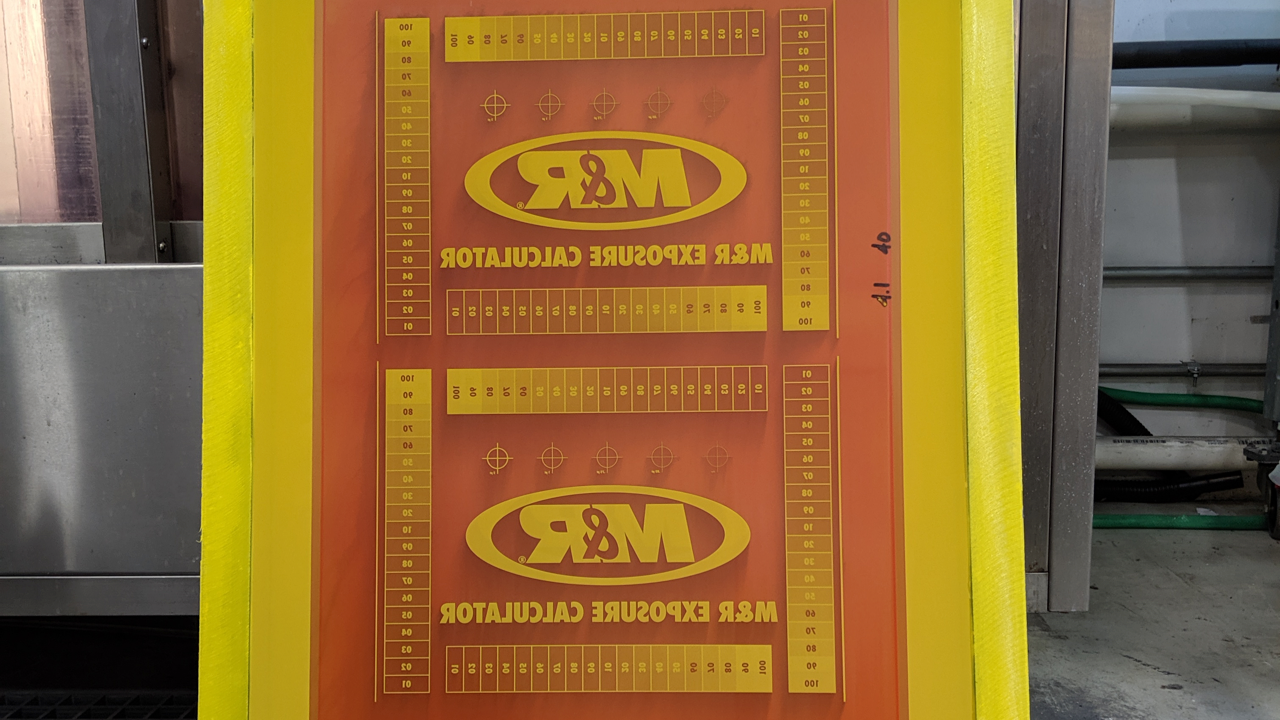

A computer-to-screen system images (or, incorrectly-but-commonly, burns) screens for screen printing. This machine directly prints a negative image onto the screen mesh, using wax or ink.

The basic CTS / DTS screen-making process works like this:

- Artwork is created

- RIP software is used to put the artwork into the correct file format for the CTS machine

- The art is printed directly onto the screen by a digital printer

- The screen is already coated in light-sensitive emulsion

- The screen is exposed, hardening the emulsion

- The screen is rinsed out with water

- Areas that the screen printer wants to print are not hardened, so ink can pass through it onto a shirt (or sign, hoodie, poster, etc.) while the hardened emulsion acts like a stencil

Traditionally, screen printers use transparent films to image their screens.

Not only is the raw transparent film required for this process expensive, the ink used to print the transparencies is costly. Additionally, the process is prone to error. Virtually every print shop has struggled with their Epson 1400 printer while printing transparencies.

Even the most skilled screen printers struggle to consistently output high-quality films for imaging screens. Perfectly lining up each film, exposing the screens, and registering the screens on press is a frustrating and time-consuming process.

Computer-to-screen systems are much easier than using film transparencies to make screens. CTS systems are precise, accurate, and far more predictable than film.

Time and labor savings due to CTS systems are huge. We’ll discuss those savings after we cover how much computer-to-screen costs.

How much do CTS imaging machines cost?

Computer-to-screen machines cost between $30,000 and $80,000 USD depending on the manufacturer, model, and exact specifications.

A note about prices: all manufacturers carefully guard their prices. The ranges quoted in this article are based on conversations with CTS manufacturers or screen print shops that have purchased CTS systems. If you’re shopping for a CTS imaging system, contact a manufacturer directly to get the best possible quote.

Here are some example price ranges for CTS machines:

- Douthitt CTS30: $40,000 to $70,000, financed for $1,250 monthly

- M&R i-Image ST: $50,000 to $80,000 and up, financing available

- Exile Tech Spyder III: $45,000 to $65,000, financing available

- KIWO i-Jet2 CTS: “more than $45,000,” financing available

- SAATI LTS 6080: $83,000 to $89,000, financing available

Some screen printers will advise you to purchase used equipment. We suggest buying new CTS machines in order to get the best service and warranties available.

Most screen print shops finance their CTS machines through their bank or an institution like CIT rather than pay cash outright. Obviously, the payments vary according to the terms of your loan.

Computer-to-screen (CTS) cost and savings calcuator

Douthitt has helped us build this simple CTS benefit calculator. Did you know that print shops are likely missing out on thousands of dollars in revenue if they’re using film transparencies to make screens?

Generate a powerful sense of how much time and money your shop can save with just a few simple inputs.

How much money can your screen printing shop make by going CTS? Here’s one way to get an answer:

Why should screen print shops go with CTS?

You don’t need math and accounting to make a case for CTS or DTS to most screen printers.

The results speak for themselves, and the shops that implement CTS would never entertain the idea of going back to film.

CTS imaging systems improve production capacity, turnaround speed, setup times, and overall efficiency.

Key Insight

“80% of the issues that wind up losing you money as a screen printer are related to your screens.” – Jon Ladd from Terminus Tees

Screen printing, as a process, is uniquely challenging. Unlike many other processes, screen printing often has to start over from the very first step (the screens) when something goes wrong.

There is an extremely low margin for error, and most truly costly errors originate from problems with screens.

Computer to screen systems tend to eliminate or reduce a litany of common problems in the screen room. These include:

- Pinholes (due to dust on the exposure table’s glass)

- Poor detail and resolution

- Poorly printed films

- Bad registration

The boost in efficiency is so high that it’s typically easier to remake screens with a CTS system than try to register and re-register poorly burned screens with a film-based system. “What used to be a nightmare is now just like, oh, I’ll be back in 15 minutes with new screens,” says Joe Zangrilli from Rowboat Creative (owner of a M&R i-Image CTS system).

The primary benefits of CTS imaging systems for screen printers are:

- Much faster imaging

- Higher production capacity

- Faster setups on press

- Consistent registration

- More efficient screen room practices

- Lower labor costs

- Higher quality prints

- Easy digital file storage and retrieval

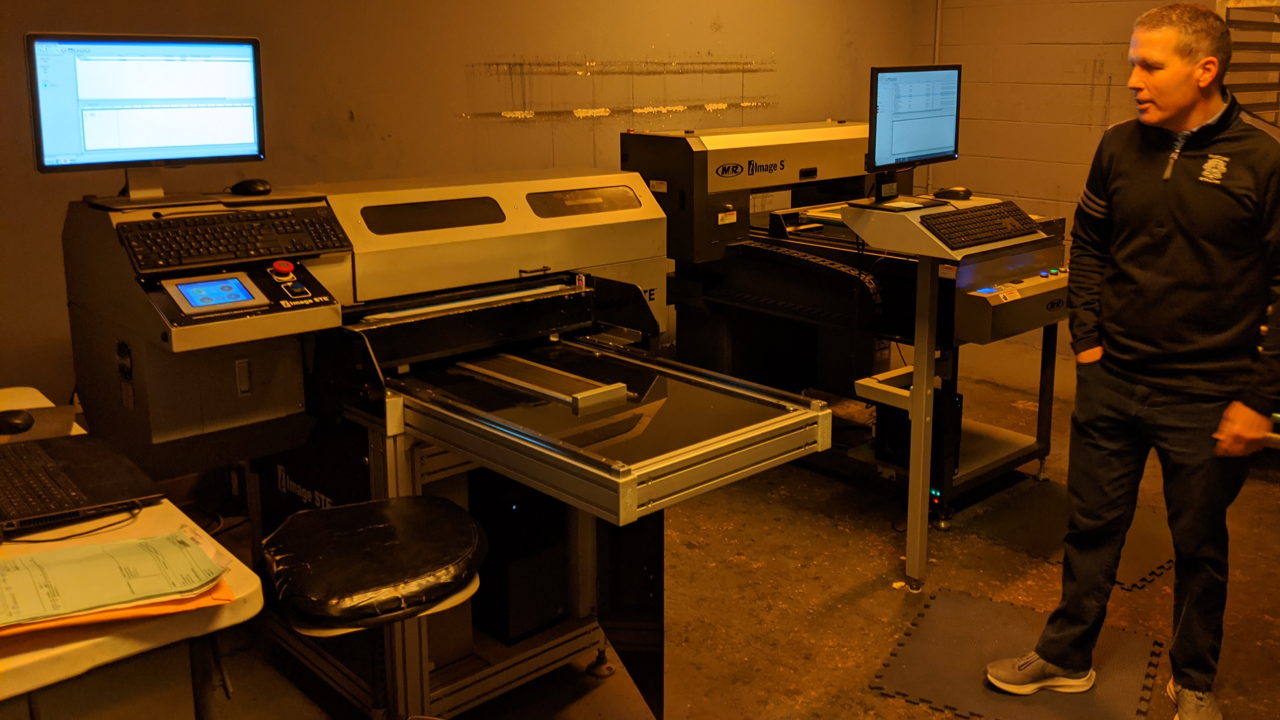

“We had one i-Image, but what happens when one goes down?” explained Marathon Sportswear’s Jim Piko (pictured above). Their high-volume contract printing setup forces them to have a backup CTS.

When should a screen print shop buy a CTS system?

“Before you buy that second automatic press, you should probably buy a CTS system,” says Jon Ladd from Terminus Tees. His business ships hundreds of thousands of shirts every year, with a major focus on band merchandise.

There is a clear dividing line in screen printing: shops that build systems designed to scale and shops that simply go day-to-day.

Shops that are not building those systems tend to be chaotic and disorganized. While becoming a big shop isn’t the only goal a business can have – being organized is crucial to sustainable business practices.

The shops that are scaling, growing, and increasing their revenue year after year – particularly past $5M in revenue – have invested in CTS imaging systems.

The shops that need CTS the most have these things in common:

- Complex art

- Why: you will likely make tremendous gains in speed and accuracy with a CTS system, particularly over the long term – and print quality will increase

- 80+ screens per day

- Why: at this size, you are likely spending a small fortune on ink and film…as well as generating a lot of operational waste and inefficiency without a CTS unit

- Reorders and film storage struggles

- Why: film libraries are tremendously inefficient. Film degrades over time. Digital storage is far superior.

- More than 2 screen room employees

- Why: the cost of 2 employees’ salary is typically higher than even the most expensive CTS system. They will be far more productive.

- Complicated separations

- Why: as you spend more time and money on complicated separations, CTS boosts accuracy and speed.

A CTS or DTS system isn’t always a financial decision, then. It is an investment in becoming a more capable print shop – not purely a dollars-and-cents decision.

Who makes the best CTS imaging systems?

Several companies manufacture, distribute, and service computer to screen systems. All of these manufacturers have crafted high-quality systems that help screen printers realize nearly instant gains in their screen making capabilities.

However, this isn’t a review. We aren’t here to sell you on one CTS, DTS, or even laser-to-screen system. There are plenty of options, and several distinctions to make between the different machines and manufacturers. We’ll ultimately leave it to you, the reader, to pass judgment on which automated screen making system would be right for your shop.

Douthitt

Based in Michigan, Douthitt has been deeply involved in all things related to screen making for more than 26 years. A family business with personable support, Douthitt has earned a name for itself by supporting their customers with extremely durable screen printing products.

Douthitt’s CTS30 system costs around $40,000 to $60,000 USD (Douthitt asked that we not quote their exact MSRP) and uses wax to print directly to the screen instead of ink. Users report multiple advantages to the wax-based printing system, including a low cost for supplies, a highly durable print for heavy exposures, and exceptionally detailed print quality.

Additionally, Douthitt has created a super-clever way to integrate Printavo with their system. You simply scan a barcode and the screen maker finds the artwork and crucial job info with no searching, clicking, or fumbling for artwork (see the video above for an example).

The M&R Companies

Based just outside Chicago (check out our tour of M&R’s headquarters), M&R is a trusted name in screen printing. Their iconic all-blue brand of screen printing equipment signifies longevity, quality, and value.

M&R’s i-Image system represents a suite of screen room products that M&R has refined and iterated on for years. With multiple models and builds, M&R’s i-Image system can be found in larger, more efficient screen printing businesses across the world.

M&R’s product lineup includes the i-Image S, ST, and STE – each with additional features and capabilities. M&R’s i-Image S starts at just under $35,000 USD, while a top-of-the-line i-Image STE (with the exposure unit included) could theoretically approach $80,000 USD.

M&R’s CTS imaging system uses ink to print directly to the screen. Even with the cost of ink, the i-Image’s cost per screen imaged is lower than traditional film.

Exile Tech

Exile Tech’s cutting-edge Spyder CTS systems are among the industry’s finest. I spoke with Exile CEO Lance Heap on the phone about Exile’s rise. “We develop and manufacture Exile’s equipment here in the United States, which makes us unique in the industry,” Lance explained.

After starting as a graphic imaging company crafting graphics for oil and gas exploration, Exile has pivoted its substantial engineering and technical knowledge toward pre-press advancements.

Easily able to image screens in under 2 minutes at 1200dpi, the Spyder III has proven itself durable enough for use at Night Owl Prints, a legendary print shop known for their mastery of water-based screen printing.

SAATI

SAATI’s laser imaging system was released in 2018.

Featuring no wax or ink at all, SAATI claims it can image onto any type of emulsion.

Interestingly, SAATI publishes their prices for laser-to-screen systems. They offer a range of laser-to-screen options for other size businesses and applications as well.

Other companies distribute or manufacture CTS systems, including:

Computer-to-screen: a worthy investment

While purchasing new equipment might feel like trying to paint a fence in the rain, CTS machines are a worthy investment for screen print shops. They are absolutely worth the time to procure, setup, and learn to use – and that’s proven.

If you’re using transparencies and making lots (80+ per day) of screens, automating your screen room is a huge opportunity. It is a simple way to use cash to make your shop more efficient, more accurate, and more profitable.

In conclusion, we urge all screen print shops that are growing, increasing their capacity, or even looking for ways to cut costs to consider CTS systems.

This is a tool to unlock huge improvements – from print quality, to time spent registering jobs, to tracking and reprinting orders.

CTS systems have proven to be the vital piece of equipment that pushes print shops beyond the $1M to $3M revenue hurdle.

Curious about the history of screen printing, film, and high-color t-shirt prints? Read about Jon Weiss and simulated process printing here.

0 Comments