In screen printing, screens come first. Struggling to build a screen room and darkroom without breaking the bank?

Even with very limited resources, you can still achieve incredible results.

You simply don’t need to spend thousands of dollars on your screen print shop’s darkroom!

We’ll show you simple tips and strategies for saving big bucks on your darkroom. Read on!

Washout booth: do it yourself?

A clean space to reclaim screens is essential to any print shop.

But washout booths can cost thousands of dollars!

Yes – an expensive washout booth can last you decades. If you have the cash, it’s a worthy investment. But you don’t actually need to spend that cash.

At Sound & Fury, we use a simple wooden frame attached to an old shower unit we purchased secondhand.

We sprayed some plexiglass with a thin layer of white spray paint and mounted some small LED lights behind it – giving us a great space to work in.

Make a screen vacuum

Want to reclaim and dry screens much faster?

Attach a narrow piece of PVC pipe with a thin slit cut in it to a ShopVac or industrial vacuum.

Ensure there are no rough edges on your vacuum attachment. Drag the vacuum along wet screens and watch the water disappear.

This is simply the fastest and best way to dry your clean screens.

Lighting: does your darkroom need to be dark?

No. In fact, your darkroom should not be dark! Since it’s a workspace, you need everyone to be able to see clearly.

You can purchase bug-safe bulbs for your darkroom. They don’t attract bugs – and they cast a warm yellow glow that’s easy to work in.

Many screen printing experts have advised renaming the darkroom as the yellow room. Not a bad idea!

Additionally, you don’t have to replace all of the bulbs in your space if that’s off the budget.

You can also block existing lights with UV-blocking film. It casts a dimmer, more amber-colored light.

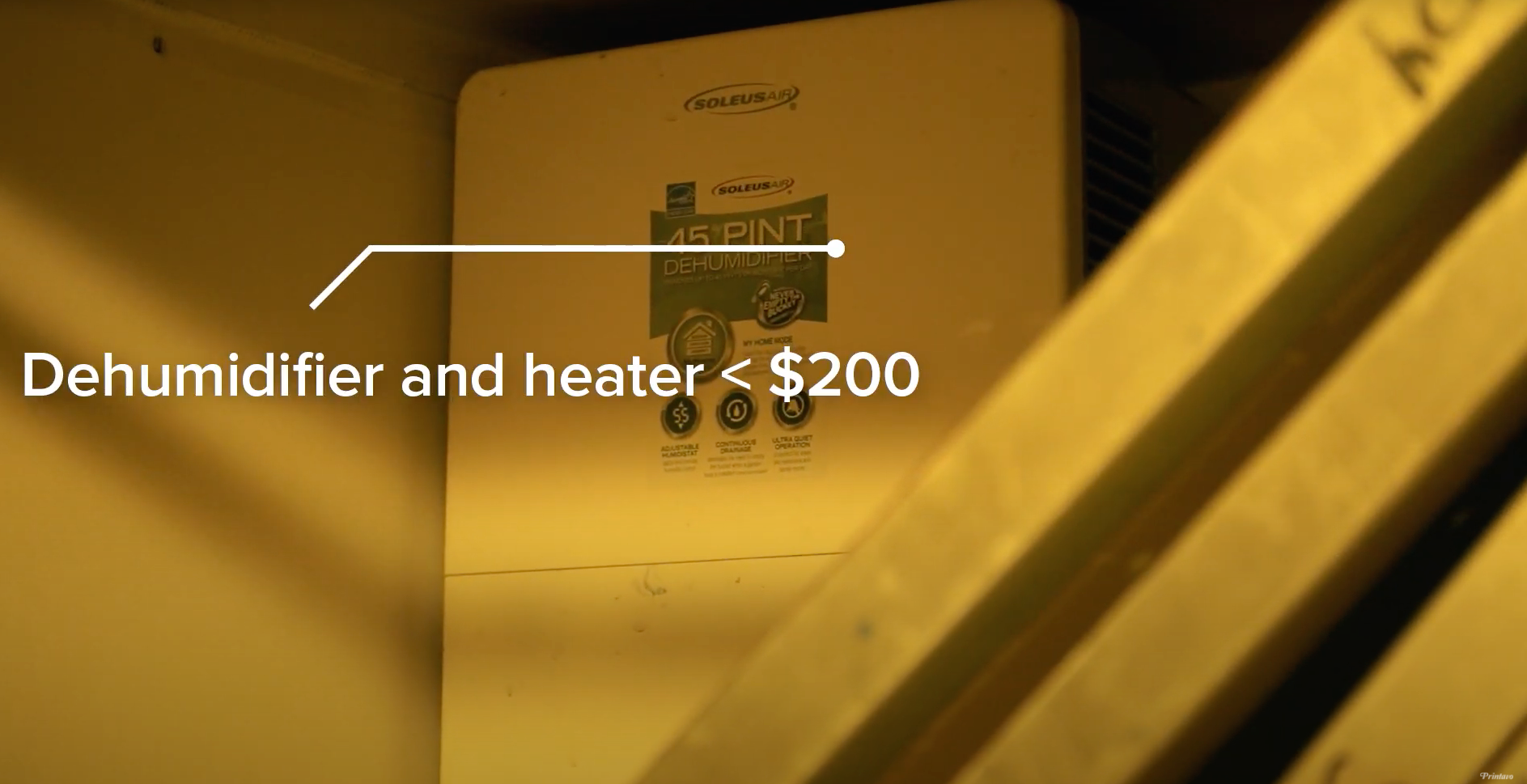

Humidity: a huge factor

Tracking humidity in your darkroom is essential.

If you’re still using film outputs, then you want your darkroom to be as dry as possible. Ideally: the drier, the better.

If you’re using CTS or DTS, you’ll want to maintain 35-45% humidity to keep your equipment operating effectively.

Measure humidity constantly with a hygrometer. Digital, wall-mounted temperature / humidity combination devices are affordable. Get one!

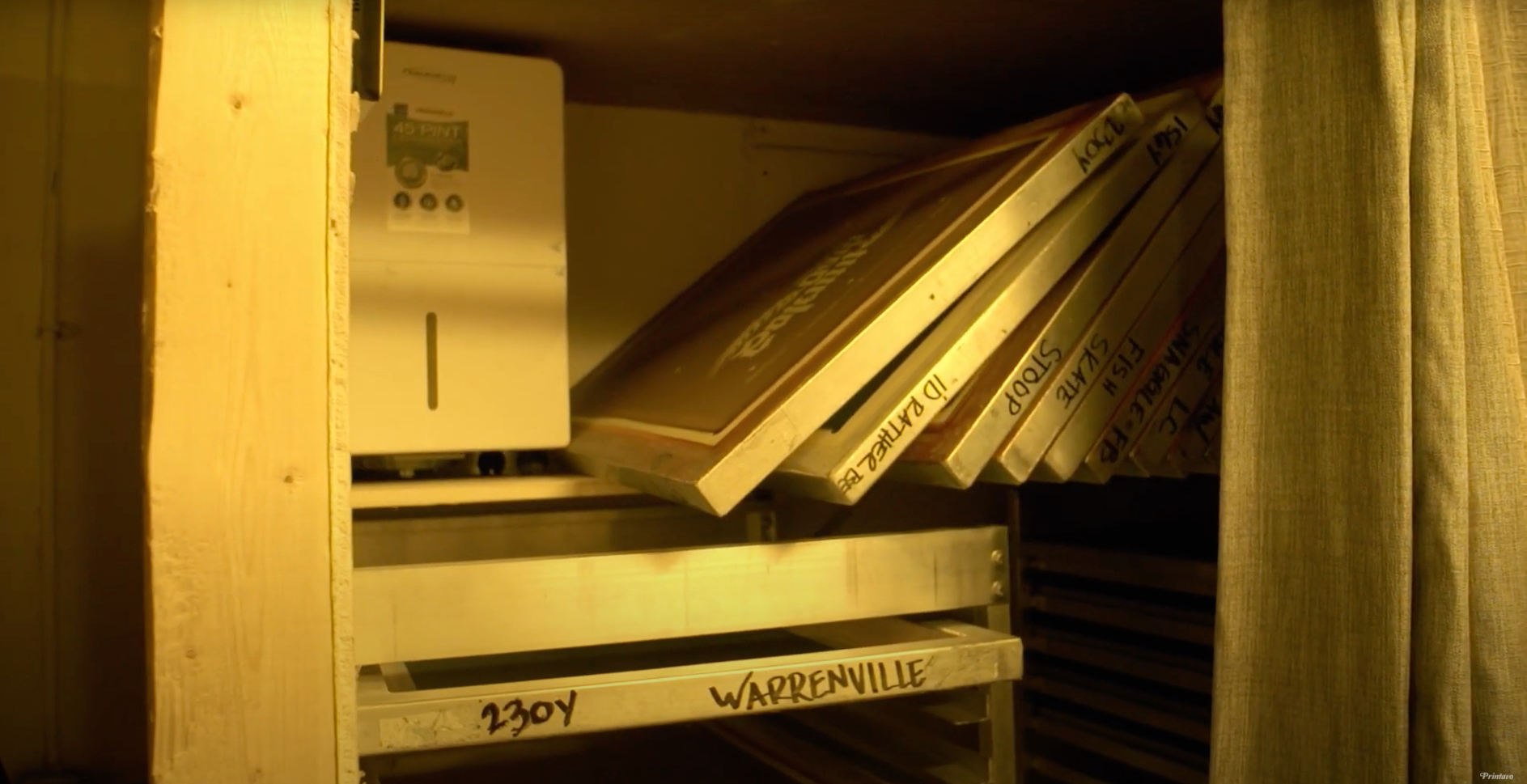

Screen drying box

Never dry your screens in an open room where you’re working!

You can contaminate them with dust – even if you meticulously dry them.

It’s simple to make a closet or wooden box as your screen drying box. You can create a dry and warm environment with little airflow so that your screens dry quickly.

Remember: start with the driest possible screens. Always vacuum your screens to speed the process along.

We used thermal curtains, a shower rod, and a small wooden “closet” area we constructed as our drying box. The goal? Keep dust and airflow to an absolute minimum.

Another tip: keep your temperature between 80-100 degrees F. You can use a small space heater to help keep your screen drying box warm.

How long should a screen take to dry?

Like so many questions in a print shop, this depends on the variables (particularly how you dry your screens, the humidity, and the temperature) in your shop.

At Sound & Fury, we can dry and prepare a screen in about 15 minutes.

Aim to get your drying time down as low as possible. This helps you if you have a screen break or another error on press that requires you to re-make a screen quickly.

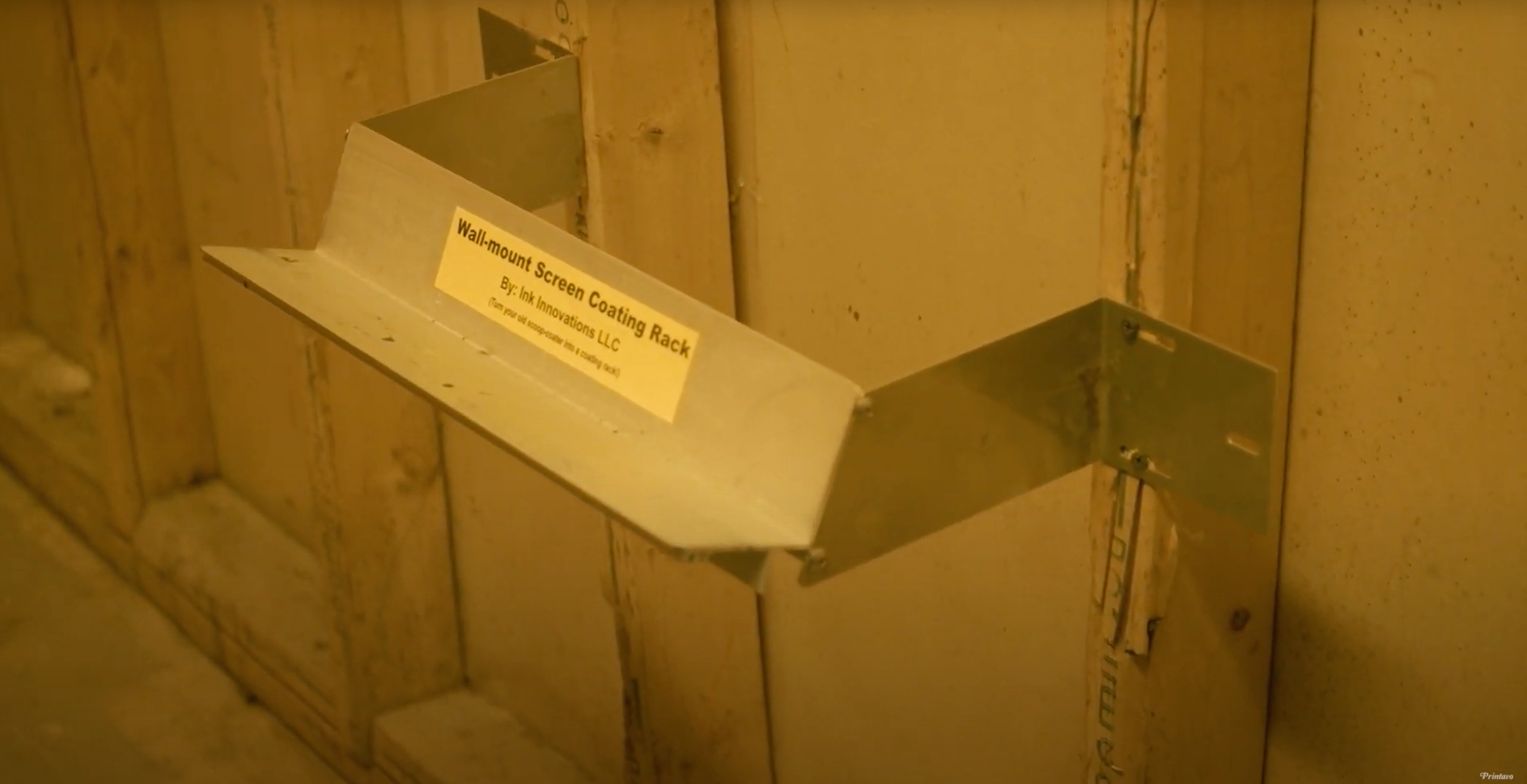

Coating screens: use good ergonomics

Remember: how you coat your screens determines how successful your emulsion application will be.

Don’t crouch over the floor or hover over a table that’s too small – invest in a screen coating rack or make your own.

This small but simple change can make a huge difference in how well you coat your screens.

Conclusion: darkrooms don’t have to be expensive

It seems daunting to need to create a darkroom on a budget – but the fact is that it’s easy (and fun) to find solutions to these problems.

A few small adjustments can also improve the darkroom you already have. Is everything simple to use, placed in a logical spot, and clean?

With some DIY spirit and a shoestring budget, you can have a “baller on a budget” darkroom too.

0 Comments