In Part 1 of Managing Screen Printers, we discussed why a culture of accountability is so important for your screen printing shop. Now that you understand the basics of a culture of accountability, it’s time to create standardized procedures as the backbone of your shop’s processes.

This is where the rubber meets the road: you are actually building systems for accountability and creating replicable steps for your screen printers to follow.

Why create Standard Operating Procedures?

Standard Operating Procedures (SOPs) sound complicated, but they are nothing more than step-by-step instructions for performing complex routine tasks. The ultimate goal of SOPs are:

- Efficiency

- Higher utilization (did you know most shops are under 30% utilization?)

- High-quality production output

- Uniform employee performance

- Reduced communication time

- Less spoilage and waste

A well-executed SOP creates clarity about employee expectations while simultaneously increasing the efficiency of your shop. If you want to be efficient, you need to create a series of steps your employees follow for every job in every department.

So why do so many shop owners skip this simple and valuable step in their business? They’re hung up on the belief that the only way to run their shop is “fast and loose,” under the (false) notion that they’ll sacrifice creativity and employee happiness if they systematize and standardize their production process. This isn’t the case, and I’ll explain why shortly.

Repetition is valuable: Learning by habit and compartmentalization

I can talk about SOPs for hours on end. This is a topic that bores some people to death (my poor girlfriend!), but I deeply appreciate the process of creating and engaging with strong SOPs.

As a kid, I had a hard time retaining knowledge. I was often behind in school because I couldn’t seem to keep everything in my head. Things seemed disconnected, and I couldn’t make sense of the “big picture.” Learning was too big of a process for me to understand. I always felt behind!

But I had to find a way to learn.

What worked for me was to create a structure for my learning through repetitive and compartmentalized tasks.

I could break down anything I had to learn into discrete parts and work to control the variables for each task one-by-one. These repetitive tasks would grow to become habits. From there, the habits built actual knowledge. I didn’t need to understand everything about what I was learning – I just had to start chipping away at smaller, easier-to-comprehend pieces and work my way up from there. When I was trying to look at the “big picture” I would get overwhelmed and couldn’t actually learn! It’s the exact same concept that makes SOPs so successful.

Screen printing is an inherently repetitive task. Because of this, it’s easy to become complacent. It’s even easier to overlook the bigger picture of your role in the production process.

Your shop is composed of multiple interdependent processes that have to perfectly mesh for flawless printing. It is too much to ask one employee to understand everything at once – much less be able to do it all perfectly.

“This is where repetitive, firm, clear standard operating procedures become so valuable: they enable learning by breaking down complex processes into digestible and repeatable tasks.”

To be brief: repetition is valuable because it builds into habits. SOPs are one way to break down everything in a print shop to become habitual – instead of relying on your employees’ ability to think holistically the entire process. This is the entire principle behind specialization!

Balancing freedom and creativity with standards and systems

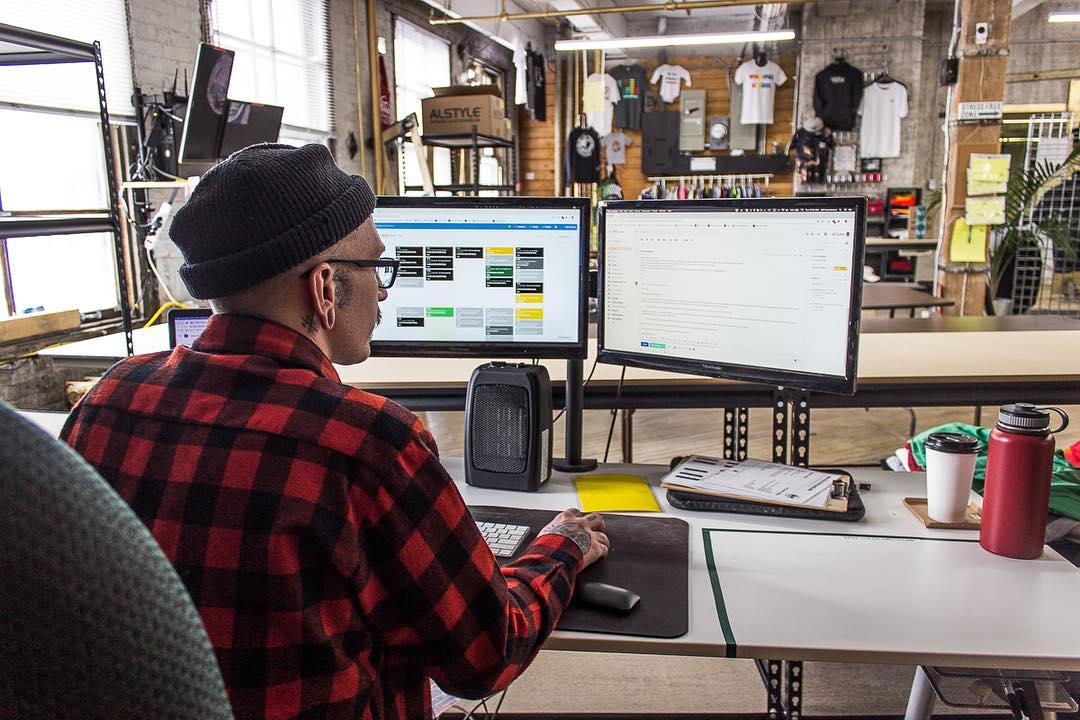

It’s fun to have a laid-back vibe in your print shop, right? Plenty of us want a shop that feels more like an art studio than a factory!

It makes sense, after all: lots of screen printers either started as artists or are still artists on the side – so the “fast and loose” style of management has immediate appeal. We don’t want to crimp our printers’ styles and hamstring them with rules and regulations that keep them constrained – but we are also printing on expensive substrates in a medium that requires an exacting and scientific approach to the process.

So how do you balance giving your employees creative freedom while maintaining real standards and systems?

You start by implementing basic SOPs and letting your employees have a stake in owning and controlling your standard operating procedures.

You will find that there is not a real trade-off between creativity and standards. Limitations, after all, tend to foster creativity rather than diminish it. The sooner you begin implementing SOPs, the less of a painful exercise it becomes. Your employees will see the writing on the wall – this is how it’s done here – and begin contributing to the project instead of fighting tooth-and-nail to keep everything “as it is.”

“Too little, too late” can seriously break the bank and hinder the growth of your print shop. It is far better to have some SOPs (even incomplete ones) than to wing it. You want to focus on areas where you’ve already made mistakes – particularly expensive mistakes – if you’re just beginning to tackle this challenge.

Principles for building your Standard Operating Procedures

You need to start crafting your SOPs immediately. However – if this is your first time doing this (and even if it’s not) you should expect there to be mistakes, holes in your processes, and gaps in your knowledge of your business.

There are simple principles to adhere to when you start this project:

- The goal is continuous improvement, not to set-it-and-forget-it. Set your sights on getting better, not a specific milestone or target. The specifics can (and should) come later. For now, the goal is to build out your processes, standardize them, and circle back often to improve them. Perfection is not an option!

- Understand which variables you can control and which variables you can’t. This will happen naturally as you examine your processes and standardize them.

- Determine which areas are under your purview and which aren’t. This goes back to accountability: what do you actually need to be involved with for your process?

- Consult if this task is above your skill level. While I would advise every shop owner to give this a shot themselves, there are plenty of consultants and advisors (like myself) who can help you achieve your standardized vision.

Tackle this project from the perspective of a learner. You are taking on a large task that you will have to break down into smaller and easier to understand pieces. Your print shop is likely more complex than you realize!

Step 1: Crafting a Needs Assessment

Begin assessing the systems in place by identifying your needs. To do this, you’ll have to go to the source and get first-hand knowledge. Here’s how to structure this process.

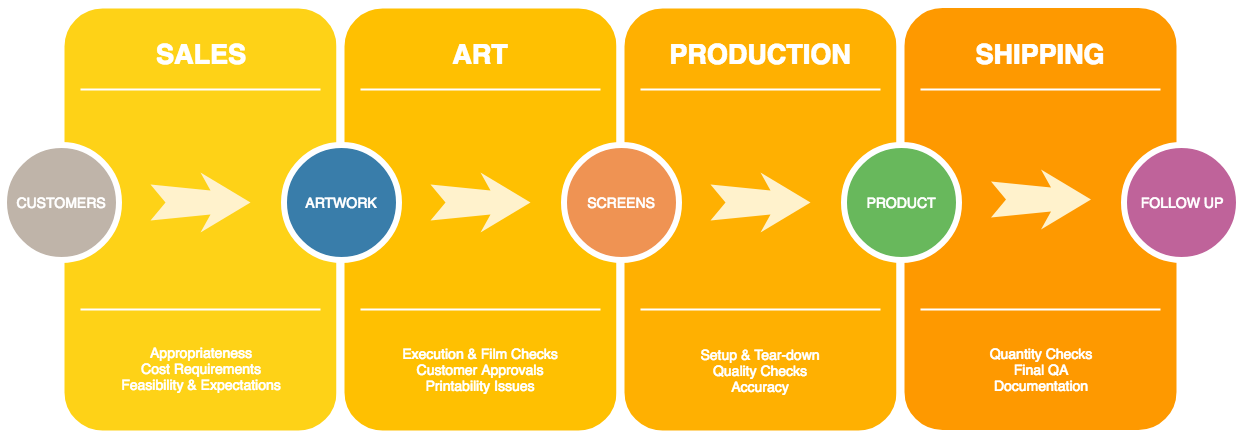

Break your shop down into departments

Simplify your shop’s overall workflow into several departments. I’ve found they are typically something like this:

- Sales

- Order intake

- Art and design

- Screens (Burning and reclaiming)

- Production

- Shipping & receiving

- Quality assurance

- Customer care

Designate department heads (if you haven’t already)

Department heads are the leaders you’ll consult with to investigate which processes are breaking down, which are working well, and which processes aren’t in place yet. They are typically more experienced or trustworthy.

These are the people you’ll want to work closely with to determine how and where to begin implementing your standards. Find the people that are already the most accountable and invested in your shop.

Communicate with department heads about processes in place

Now, the big challenge: get buy-in from your shop’s leaders and start working with them to identify what’s already happening – and what needs to change. Find out from the source what the problems are. Some areas to immediately explore:

- What knowledge gaps are there in the department?

- Is there applicable continuing education, another shop you can consult with, or a solution at hand?

- What processes are confusing, time-consuming, or prone to failure?

- What tasks are redundant?

- What tasks are low-value? (Further: can these tasks be removed or automated?)

- What needs to be standardized?

- What shouldn’t change? (Asked another way: what’s already working well?)

- What do you need to do your job better?

Looking at your shop from your perspective seems like you’re getting an accurate picture. But it’s the case, time and time again, that shop owners are missing part of the picture. You’ll be surprised to find that there are already some “unwritten procedures” in place!

Starting with an honest accounting of the department heads’ needs simplifies your SOP development – and grants you a clearer picture of where your shop’s problems actually are. Once your department heads have a stake in the discussion, they’ll want to help you improve your process.

Step 2: Formatting SOPs – Getting visual

I recommend spending some time with a tool like Draw.io to craft a workflow. You’ll be able to identify the outcomes and processes that already exist before you begin building your SOPs. From there, you can begin comparing your estimated workflow to your actual workflow after you develop SOPs in tandem with your department heads.

Ultimately, there’s no “correct” way to format your SOPs. It can be a document, a flow chart, an in-depth training manual, videos, a laminated checklist, or even a poster in each department. You have to work with your department heads to create the right format for their process!

“Leverage flowcharts and mental maps. One of the simplest and most valuable exercises you can do is to complete a flowchart-style map of your shop’s process from job intake to job completion. This doesn’t take a lot of time and will offer you some real context for each step of your screen printing process.”

What did you overlook? What did you focus too much on? Were there gaps in your process that you discovered? These can inform your decision making as you move forward and uncover weaknesses that you were unaware of. Anything that can be systematized should be uncovered and considered at this stage.

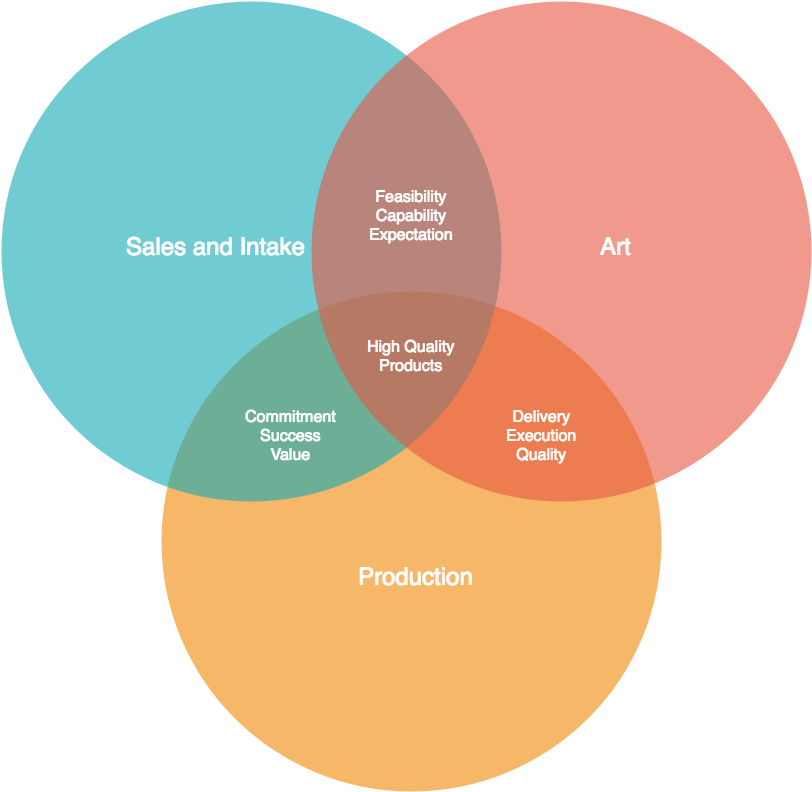

Step 3: Upstream and downstream integration

This step focuses on dependencies between your departments.

Work with each department head to review how and when their departments rely on other departments.

Consider the example of an art department. Immediately upstream from your art department are your sales and intake departments. The head of the art department will need to review and understand the procedures in place for sales and intake that directly affect them.

- Do the sales and intake teams have a clear set of expectations for customer art?

- Is there a system in place for the art department to communicate with the customer for approval?

Immediately downstream from your art department are your screen department and your production department.

- Does your art department do separations, or check with production about print size and placement?

- Do they mock up virtual proofs for customer approval?

Formalizing how each department fits in with the department before and after it creates a streamlined production process. There can be significantly less back-and-forth between each department. Otherwise, there’s a lot of gray area and a lack of overall accountability – it’s easy to pass the buck on to the next department and claim “I didn’t realize” or “I didn’t know.”

Root out areas that have caused confusion in the past during this stage. Aim to reduce the amount of time the departments need to spend interacting. Good SOPs account for the tasks that affect each department’s ability to execute.

This is where your flowchart and mental mapping exercises become powerful: you’ll see how each department fits into the “big picture” of your production process.

Step 4: Creating stop-gaps

The term “stop-gap” has different meanings. In a production capacity, I’m referring to a:

Stop and check process to ensure quality and correctness.

The overall goal is to stop errors before they go very far by having redundant checks against common failures. This makes it hard for errors to get to the customer. It adds a negligible but valuable amount of time to your overall production process (and will, in the long term, reduce spoilage).

The most basic form this takes is a checklist with an area for your employees to sign off on. This can travel with the job or be part of the department’s station. Documentation of errors and problems will reinforce your efforts at constant improvement!

You can build your first and most effective stop-gaps around problem areas. This can be something simple like a QA check for the first print, or something more complex like an art approval checklist that accounts for the customer’s expectations and your production requirements.

Example: Art Department Film Output Checklist

- Label all films correctly (as laid out in training guide)

- Choke underbases to allow for proper overprint

- Ensure proper film opacity

- Ensure films line up correctly

- Ensure films match customer’s output size requirements

- Check films with screen department before burning

- Store films correctly after screens are burned

This same list should be abbreviated for the screen department’s stop-gap process during intake. You’re not aiming to eliminate every redundant process – but you are aiming to use redundancy to add value by increasing your shop’s overall accuracy and effectiveness.

Step 5: Implement, revise, revise again

Once you’ve gone through the process of developing your set of departmental standards and procedures, it’s time to implement it.

I recommend a move-fast-and-fix-it-early approach: it’s far better to begin implementing a half-finished system than wait for the perfect approach to appear.

You need to revise and revisit your policies often. Your shop is never “complete” and it’s crucial to embrace the mindset that improvement and process are the most important components of your shop’s success. I suggest, at a minimum, spending a week to go in-depth with your policies and standards once a year. Ideally, you’ll be able to do this during a slow period in your year (January is a fantastic time for setting goals and revising your processes).

As your shop changes, you need to revisit your processes as well. When you finally upgrade to that amazing direct to screen unit, your SOPs for preparing art files will be upended. Each new machine you add requires integration into your process!

In the next article

This is part 2 of an ongoing series written from my knowledge and experience running large screen printing shops for high-volume clients with demanding turnaround times. It’s called Managing Screen Printers. Check out Part 1 right here.

Next time, I’ll discuss how your standard operating procedures can become the scaffolding for successful and meaningful employee reviews. I’ll offer up some downloadable examples you can use!

Stay tuned and keep laying down that ink!

0 Comments