The number one question that screen printing shops have is a big one:

How do I set my screen printing prices?

The most basic calculation is this:

(Garment Price * Garment Markup) + (Printing Fee – Quantity Discount) = Price Per Garment

You can get extremely detailed with pricing. Some owners leave nothing for granted and account for things like their shop’s overhead, time on press, capacity, impressions, number of colors, t-shirt costs and so on – you absolutely should account for those nitty-gritty details. But that’s not all there is to pricing.

Instead of trying to develop an all-encompassing formula, it’s best to follow some general strategies for smarter pricing. The reality is that you’ll need to price every unique job differently.

Here’s what successful shop owners do to price their jobs:

- Calculate a reasonable garment markup

- Understand the job before pricing it

- Price for complexity & difficulty

- Give discounts when appropriate

- Price for their business, not against their competitors

Contents

- Calculating a garment markup

- Understanding the order

- Pricing for complexity

- Discounts

- Setting YOUR prices

- How to make a screen printing pricing matrix

1. Calculate A Reasonable Garment Markup

You’re paying to buy t-shirts from wholesalers. This takes times and money, and it’s the first step to printing custom t-shirts. Your garment markup is the first place that you should make profit.

The industry’s standard markup is 150 to 200% of the garment’s wholesale cost. Most people explain the same markup as a “fifty percent (50%) markup.”

This means if a garment from a wholesaler costs $5, you should charge between $7.50 and $10.

It’s crucial that you cover the costs of procuring unprinted goods.

Your standard garment markups can be easily broken down into three categories: basic items, mid-tier items and premium items.

You can use screen printing management software to help you automate this process.

Basic Item Markups (T-Shirts and affordable goods)

Basic goods should have the highest markup (200% or more). This seems counter-intuitive, but there is a good reason.

Why should your markup be higher on less expensive items like t-shirts? Because you can easily justify the prices to a customer.

It’s not unreasonable to price a basic screen printed Gildan t-shirt at $10 or more.

That t-shirt may cost you just $1.50. But there is a real labor cost for procuring, processing, and printing the shirts in your shop. This fixed cost does not depend on how much you paid for the t-shirt.

The less a garment costs, the more you can mark it up.

Middle-Tier Item Markups (Hoodies and more)

As garments become more expensive, your markup may actually go lower.

Many shops find that the total they net gets lower as the garment’s price goes up.

You can offset the lower markup with a higher printing cost.

Garments that cost $10 from a wholesaler are typically marked up by about 150%. A $10 sweater becomes $15 for the customer. Some examples of clothing with lower markups:

- Hoodies

- Zip-ups

- Premium athletic wear

- High-quality T-shirts

- Long-sleeve shirts

You may also find a quirk in the math: you’re netting a larger dollar amount, even if the markup percentage is lower!

You may have to pay to replace spoiled garments, so it’s vital to cover your costs with a higher printing or setup fee. Marking up mid-tier items appropriately is essential.

Premium Item Markups

If you’re paying more than about $15 for something you’re printing on, it’s a premium item. This includes pricier items like:

- Jackets

- Coats

- Reflective work wear

- Outerwear

- Backpacks

Your markup should go lower, and your printing fee higher, as the price of the goods gets higher.

It’s not unreasonable to keep a 150% markup for some of these items. But a higher markup may make the price too high for some customers.

For example: a $20 wholesale price translates to a $30 customer price with a 150% markup. That’s before you’ve even applied the cost to print the garment!

It may be easier to set a dollar amount for your markup on expensive items.

If we’re targeting our markup at $4.50 per garment, it’s a 122.5% markup. Now that plush hoodie costs $24.50 before printing instead of $30.

Tip: Charge more for printing and setup on expensive garments instead of a higher garment markup percentage.

To recap: having one garment markup for all types of t-shirts, jackets, and hoodies you sell and print on…is unwise. Appropriately price your garments for the customer. Lower cost goods need the highest markup, while higher cost items require a lower markup. Higher cost items are more profitable, but also riskier to print on.

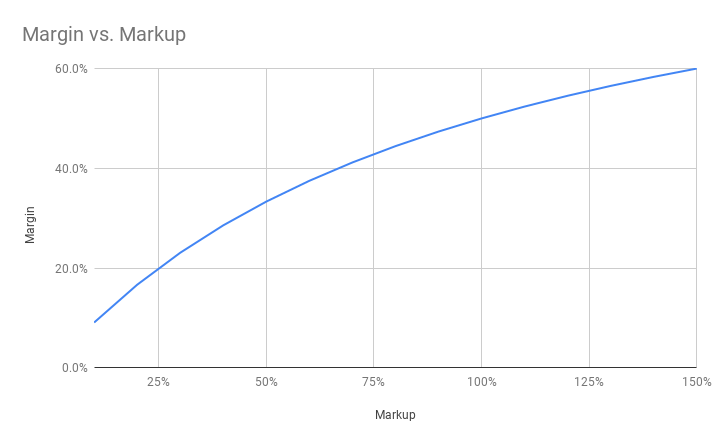

Further reading: Margin versus markup

It’s crucial to understand the difference between your markup and your margins. They are not the same!

For example, a $1 garment sold to the customer at $1.50 has a 50% markup – but only a 33% margin.

How margin and markup are related – it’s not a 1:1 relationship!

We have created a guide to help you understand these two crucial ways to quantify your profits and understand your cashflow. Learn more about markup versus margin here.

2. Understand The Job Before You Price It

To determine how much a screen printed t-shirt will cost, you need to understand exactly what’s required from the customer.

You should never offer a customer a screen printing quote for a job that you don’t understand. This is why we can’t tell you exactly how much you should charge: there are so many variables that come into play. Each and every shop is unique, and each job is unique on top of that.

There are several common factors related to the screen printing process that we can use to anticipate your printing cost and price jobs appropriately:

- Print Locations (where the prints are on the garment, and how many there are)

- Number of Ink Colors (how many colors you’ll use in the design)

- Flashing (whether you’re using a flash curing unit to cure your underbase)

- Automatic vs. Manual Printing (whether your shop can print quickly or requires more time to print)

- How The Product Is Sold (online stores vs. retail vs. shipped)

Your goal is to evaluate the job’s requirements and create a plan for how you’ll make the customer’s idea a reality…then create a quote that is fair to your business.

You need to understand the job before you price it. Here’s what to consider.

Print Locations

If you have more than one print location, it’s like you’re printing 2 shirts. Removing the shirt from the press and replacing it for another print location takes more time and labor.

Novice screen printers may think a 4-color job is more complicated than a simple 1-color print in two locations. But this isn’t true. Printing a 4-color design on the front of a shirt takes less time than printing two separate designs: you have to remove and replace the shirts for that second print location.

You should price print locations according to quantity and complexity.

Our advice? Price multiple location prints like you’re printing a new garment each time. This could mean charging your print fee two times. You could offer a different price for sleeve prints, neck label prints, and so on. Perhaps the back print is 50% of the original print fee.

For complex locations such as pant legs, pockets, or custom sewn tags, consider an additional fee per garment or a small charge for the entire order.

Don’t discourage multiple print locations. Correctly raise your prices for the additional labor, supplies, and complexity that multiple print locations introduce.

Number of Ink Colors

Printing one ink color on every job would make the world a more boring place – for your screen printers and for your customers. But you have to charge more money for the increased complexity that colors introduce.

A 6-color print is just much harder than a 2-color print.

But screen printers are in a tough spot.

You can’t just price your ink colors linearly. You can’t just charge 6x the price of a 1-color print. Customers want colors!

No one likes to see their products turn boring because it’s too costly. However, each added color means:

- More time on art and separations

- More time mixing ink

- More time burning screens

- More time reclaiming screens

- More time taping screens

- More time setting up screens

- More time printing

More time. More risk. More headaches. But…colors!

Yes, there are more variables and more risk involved with printing more colors. So more color does mean a higher cost.

So how should screen printers price colors? Build a “plateau” in your pricing model. One color should always be affordable. The jump to two colors is sharp, but not so sharp that customers can’t get what they want. And the jump between four colors and eleven colors should be massive!

To determine a “sweet spot,” take an inventory of your shop’s skill. Are you good at printing with a lot of colors, or is it a challenge?

The simplest way we’ve found to handle color pricing is to add a flat-rate fee to the order. Here’s how it worked:

- Offer up to 4 colors for $10 per color, plus a small print fee per item (say $0.10 per color per garment)

- Beyond 4 colors, charge $100 per color, plus a larger print fee

This way, customers can still get colorful prints if they’re serious – and you can still accurately price your jobs based on their difficulty.

Flashing

Flashing your screen prints requires more time – and it’s important you are compensated for it.

A two-color print job with a 60 second flash is not the same as a two-color job with no flashing. Flashing will take more time, introduce more risk, and present more possible production problems.

At Campus Ink, we’ve even allowed customers to add more colors at a lower price if there’s no flashing involved.

If your shop prints manually, you must account for flashing in your pricing – your workers are the ones that have to pull that squeegee and wait while the shirt cures!

So how do you price for flashing?

Add 1 to 2 colors to your standard pricing when you have to flash a job. I’ve created a separate price matrix for flashing jobs. To get an even more accurate picture, try timing two jobs with similar prints – one with flashing and one without. How large of a difference is there?

Remember: underbases often require flashing. Be ready to discuss underbases with your customers and explain why a simple print that is only one color may require an additional fee.

Automatic vs. Manual Printing

Screen printing pricing is volume-based. Most print shops really want customers to order as many goods as they can: it’s far more efficient to print 300 shirts than three.

But if you’re a small shop (or just starting out) doing a four-color job with flashing on 75 pieces will take a ridiculously long time to print manually.

Therefore, you need to adjust your pricing based on whether you use an automatic press or a manual press. Even if you are using an automatic press, you still need to account for flashing costs.

Once you cross the threshold into automatic printing, you can begin to distribute price breaks a bit more generously. Until then, be sure to account for the added labor & time constraints that manual printing adds to the process.

You can tell this creates a bit of a problem for new screen printers: the guy with the big automatic press is cheaper than you are. But there are still lots of ways that your small shop can add value to customers.

Remember: customer service is a marketing opportunity, and print shops are uniquely situated to create a truly memorable custom experience.

Online Stores

There are customers that might make ideal candidates for an online store at your print shop.

This is a premium service – but it’s how I built my business and got started in the screen printing industry.

There’s a huge opportunity to make sales to groups, teams, and organizations that are challenging to deal with – you can simply make an online store into your ordering platform.

I suggest adding at least 10% more to your prices if you’re doing online fulfillment through online stores.

In my shop, we add a flat fee on top of our traditional screen printing prices (between $1 to $5 per garment depending on the job). It will add costs to your business (such as bagging-and-tagging) – but it can also boost your revenue and open up new sales opportunities.

Need help getting started with online stores for screen printing? Check out The Ultimate Guide to Online Stores for Print Shops and Screen Printers – with custom sales and marketing materials you can download.

3. Price For Complexity & Difficulty

While we addressed some common process challenges above, there’s another layer to reckon with: complexity & difficulty.

I don’t just mean a challenging print job or design – I mean a challenging customer!

This is what I call “the forgotten cost.”

Difficult customers and jobs drag your team down and cut into your profits. It’s administrative and customer service work tacked on to design and art work.

Let’s say a customer calls in and wants 100 shirts printed.

They tell you it’s a three-color front print. Great! Easy-peasy, you think.

You mock up the job, and then send over a quote after you’ve thought through everything. They approve the quote, then send over the artwork.

You sink into your chair when you get the email. It’s a terrible JPEG.

They want a crazy simulated process print.

The art needs to be created from scratch.

You realize you’ll need to print through special mesh just to capture the details…and pay extra to outsource the separations. You’re in panic mode.

When a job’s art sends you into crisis mode, raise your prices!

Stress, panic, and frustration are the forgotten cost.

There are three tiers of complexity and difficulty that I’ve priced into my shop:

1. The “Simple” Artwork & Pre-Press Process

I give a 5% discount on the price when artwork is easy to deal with.

These are the dream customers that seem to not only know what they want – their job is easy to print. Seriously!

Here’s what I look for to apply this pricing break:

- Print-ready artwork directly from the customer with minimal artist involvement

- Simple screen requirements (like 110 mesh)

- Clear garment requirements from the get-go

- Easy planning and set-up in your shop

- Great communication from the customer with little back-and-forth about artwork

- If it’s a reprint of their existing art or logo

My life is easier. My shop’s workers are happy with the easy job. The customer is happy because I gave them a discount. Everyone wins.

2. The “Normal” Artwork & Pre-Press Process

Most of the time, life won’t be as easy as the simple jobs. There may be a few hiccups and roadblocks, but the job is mostly smooth sailing.

This is the standard experience with customers at my shop. My basic pricing model accounts for the following:

- Basic artwork manipulation, with one or two revisions from the artists before approval

- Some back-and-forth with the customer about garment requirements

- No need to solicit help from other screen printing experts to accomplish the job

- Decent communication & follow-up from the customer – no hounding them for approval

- Easy-to-moderate planning, setup and labor requirements to do the job

- A reprint, but with some slight changes or tweaks

These types of jobs are your day-to-day bread-and-butter.

They’re not super exciting, but they’re not boring either – maybe there’s a challenge or two, but it’s something you’ve tackled before.

3. The “Nightmare” Art & Pre-Press Process

It’s worth charging – at minimum – a 10% premium for these nightmare jobs.

I have a love-hate relationship with jobs like this.

On the one hand: they really push our shop’s limits, challenge our skill set and bring out the inner artisan. They’re rewarding when they work out! More importantly, these customers can be converted into lifelong customers and educated about how to make the process easier.

On the other hand: they can be costly, they’re risky, they might lose you money and they can easily ruin customer relationships if they don’t turn out well. Bad reviews are a huge risk with this kind of job, so carefully consider whether you can realistically handle the extra workload for a needy customer or a really challenging print job.

You can’t tell a customer that you’ll just experiment until you get it right – and you can’t afford to do that, either!

Here’s what’s involved with my highest priced jobs:

- Many artwork revisions, or serious challenges for your artists

- Significant back-and-forth with the customer about garments

- Unrealistic customer expectations (or an unreasonably irate customer)

- Require serious homework, like asking your expert friend how to get it done

- Long wait for approval or poor communication

- Rush order requests turn into rush order demands

- A reprint, but with totally new requirements or significant revisions (particularly on a tight deadline)

Yes, you are an artisan. Yes, this is your craft. But you are a for-profit business. Don’t give away your hard work.

4. Give Discounts – When Appropriate

There are two common discounts you should keep in mind: quantity discounts and relationship discounts.

Some customers are more valuable than others.

If you really want to make more money screen printing, you’ve got to focus on the highest-value customers that bring you the most profitable jobs.

This is called the Pareto Principle. 20% of your customers account for 80% of your business. They’re the customers we want to give VIP treatment.

Quantity Breaks and Discounts

Offer discounts for large quantity orders.

The easiest way to do this is to separate orders into tiers by quantity. You (hopefully) already do this!

The discount can be a percentage per garment, a percentage off the total order, or even a different cost per garment as you climb the ladder toward large orders.

A customer that orders 100 shirts is more valuable than a customer that orders 15 – and a customer that orders 10,000 garments is making you orders of magnitude more money than either of those. It simply makes financial sense to offer a discount to your largest customers.

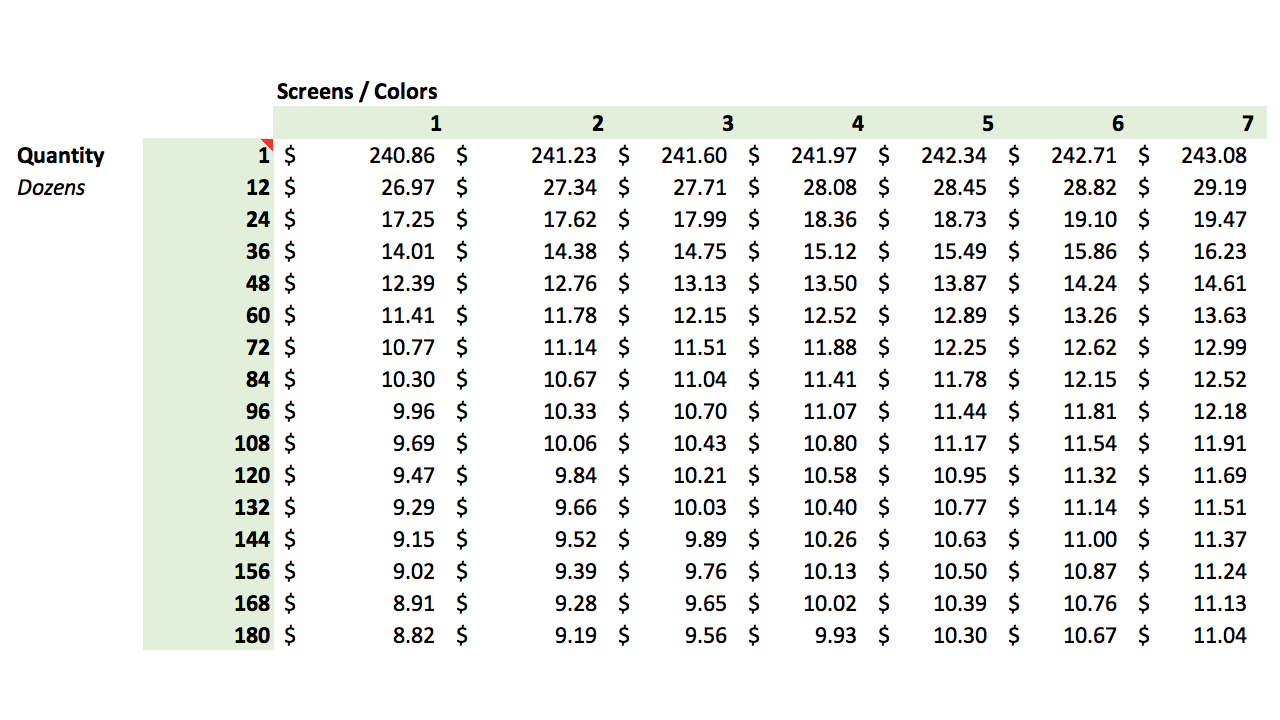

The pricing matrix generator below allows you to implement breakless pricing, which is really just a fancy way to say you calculate your prices for every quantity individually.

Instead of having one price tier for 24 to 48 garments, you price out every garment quantity individually. This way, your customers are not incentivized to order “just a dozen more to get a discount.” They get the appropriate discount every time. This prevents Mark Coudray’s “print shop pricing trap” where your quantity breaks actually work against you (see the video for a further explanation of how this works).

Relationship Discounts

Maybe you call it the “friends and family discount,” but the best way to think about it is that a discount can act as a gesture to keep a great relationship with a customer.

It’s worth keeping a good rapport with a customer that’s going to return again and again to your shop, even if it means keeping a lower margin on their orders.

It’s also worth keeping a great relationship with a customer who’s got influence in your town or community.

You don’t want to upset your local government, university, doctor’s office or Little League organization!

Be sure you point out any discounts on your invoices. Something small like a 3% discount can be meaningful if you present it as a gesture of kindness & appreciation.

Here’s a BIG tip from Jon Ladd at Terminus Tees:

“Always point out what you’re giving away. Even if the price of the shirt actually accounts for it. We show a line item for ‘FREE’ screen output and set-ups at $20 per color and side. Customers love this. They love getting something for free.”

The discount is psychological – setup fees are already baked-in to my pricing! – but if I present it to a customer as a discount, they’ll be very grateful.

Even if a discount is largely symbolic, you can curry favor & make customers come back if you point out that you cut them a break on pricing.

5. Price For Your Business. Not Your Competitors.

Pricing has to be unique to your business.

There is no magic equation or spreadsheet to perfectly price every screen printing job for every shop.

Cover your costs: pay your workers, yourself, your bills and everything else. Don’t starve your business because you’re worried about competitors offering a slightly lower price.

You’re probably not going to be able to compete with Custom Ink for market share. You may not even be able to compete with your rival shop, much less a local contract printer on price.

If you’re trying to compete with Custom Ink, you’re going to go out of business.

Don’t price your jobs according to the standards of your competitors. You’ll hurt your business in the long run.

Keep your work high in quality and keep your relationships with customers in great standing – it’s easier to say no today than to explain why that big & challenging order didn’t turn out well to an irate person that’s highly respected in your city.

I’d love to tell you exactly how to price every one of your jobs – but the truth is you have to price for your unique business situation!

Creating Your Own Screen Printing Price Matrix (With Downloadable Spreadsheet)

The #1 question screen printers and print shops have is “How do I set my prices?” This is a topic as controversial as it is difficult – every shop we talk to at Printavo has a different strategy for their screen printing pricing.

We’ve spent several months developing a way to encourage responsible pricing. We are not accounting or pricing experts, but we knew that we could add something valuable: what if we could help print shops generate a price matrix for every job they print?

There are lots of tools, softwares, and methods for developing a pricing model for screen printing shops. We wanted to arm you with something simple that you can use to generate a screen printing pricing matrix.

From there, you can take the wheel and make your own adjustments for your own unique financial situation. Here’s what we came up with:

Let’s dive in and show you how to get started! First, download the screen printing price matrix spreadsheet below:

Update for version 2: a huge thanks to Andrea Harmon from Idaho Shirt Stack for her help. She corrected several errors on the first version of this spreadsheet.

To use our screen printing pricing matrix generator, there are 7 essential steps. It’s important to understand them all so you can get the most out of the spreadsheet (and modify it for your own purposes). The 7 basic steps are:

- Set a goal profit percentage. This helps you base your prices on your goals instead of merely covering your costs.

- Define your shop’s monthly costs. While your costs may change, we suggest using a “slightly higher than average” number for your monthly costs. We’ll use these values to help calculate a “cost per impression.”

- Tell us about your shop’s production capacity. You’ll define some metrics (which you may or may not know, but can generally estimate).

- Impressions per hour. How many times can you print in an hour? Here, we mean the number of times you pull the squeegee across the screen.

- Your utilization rate. How much of a working day is spent actually printing? We give you a range of values (from 5% to 50%). Be aware that the typical shop operates at less than 30% utilization!

- Number of presses on this specific job. How many presses are going to be operating at the same time on this job?

- Set your garment price and markup. How much does each garment cost, and how much do you want to mark it up by?

- Tell us your hourly labor rate for setup and break-down. How much does administration, art, and your screen room employees cost per hour?

- Tell us how long setup and break-down will likely take. How long do you estimate spending on administration (sales, communication, data entry, etc.), artwork, and pre/post press activities (screen burning and reclaim, setup, etc.)?

- Modify the price matrix as needed. You can alter quantity, the number of screens/colors, and more.

You can invest as much or as little time in calculating accurate values each step as you choose.

Initially, you may need to estimate certain values (or develop a plan to collect more data) to get an accurate value. As the saying goes, good stuff in, good stuff out. The more accurate your inputs, the more accurate your price matrix eventually is.

Step 1: Select your profitability goal

The first step is defining the percentage profit you want to make. You select a percentage from the drop-down menu. The higher the percentage, the more the tool will charge per screen printed impression (and the higher your shop’s suggested hourly rates and daily revenue targets will be).

How this number is used: this value is used to calculate an idealized cost per impression. Since you are not inputting your revenue – and this is a forward-looking calculation – we provide you a “target revenue” based on your costs plus the desired percentage of revenue above those costs.

To clarify: if your shop has $1,000 in costs per month, your target revenue (at 50% profit) would be $1,500.

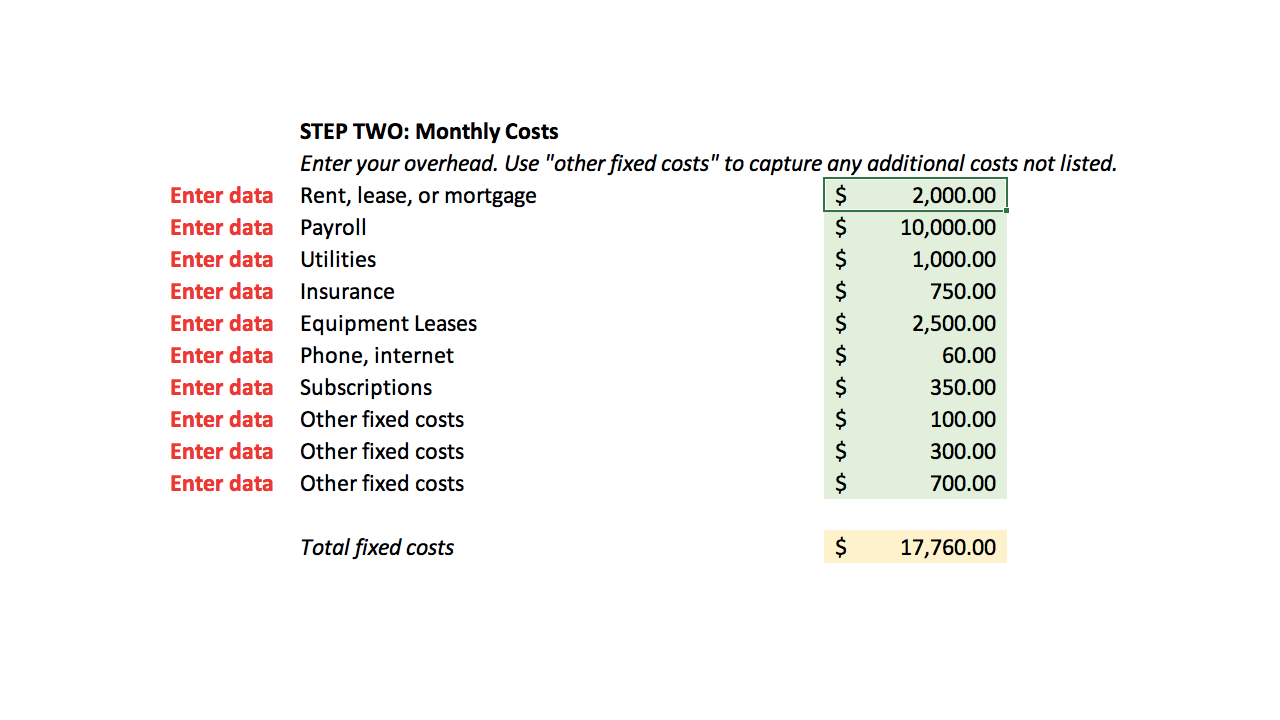

Step 2: Input your monthly costs

The second step is to input your monthly costs (overhead). We’ve provided you with the following basic costs:

- Rent, lease, mortgage

- Labor expenses

- Utilities

- Insurance

- Equipment leases

- Phone, internet

- Subscriptions

- Other fixed costs

We’ve provided three extra cells for additional costs. This is where you may want to play your variable costs: office supplies, inks, tape, and other consumables. We can’t anticipate every shop’s different costs, but these cover most of the bases. We’ve found that labor expenses, rent, and equipment leases are typically the lion’s share of a small-to-medium print shop’s monthly expenses.

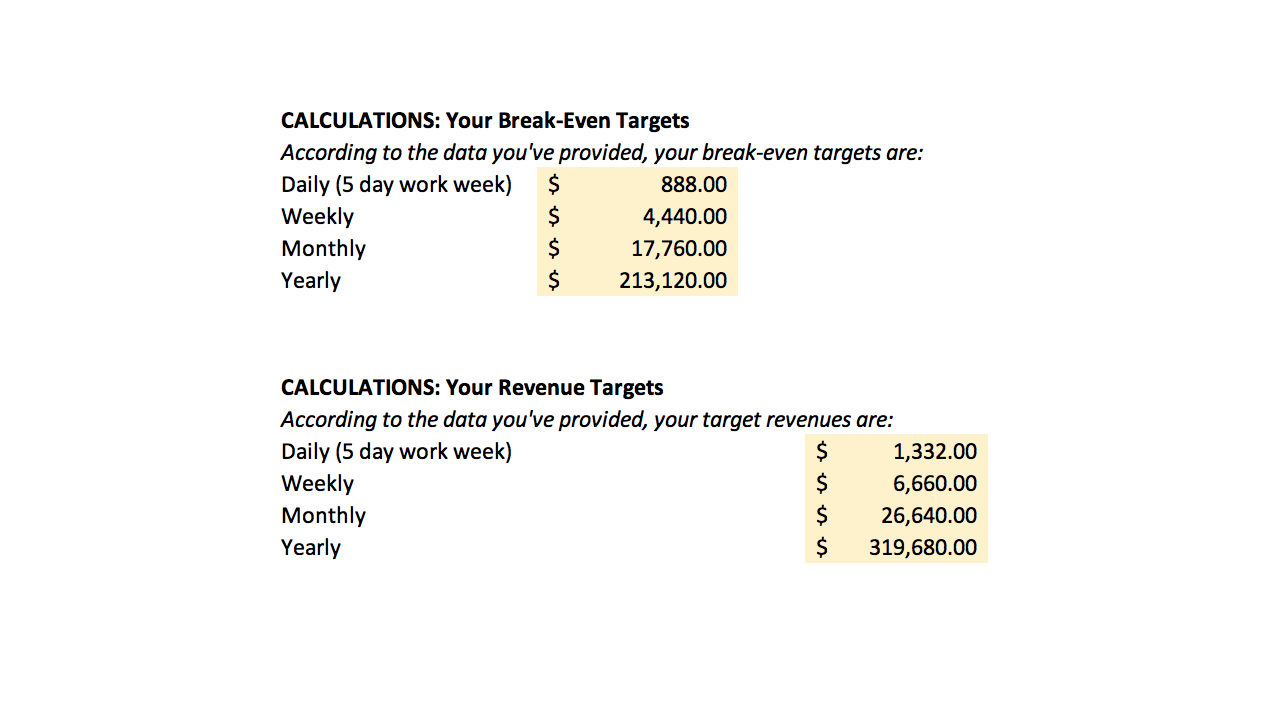

How these numbers are used: these numbers are used to calculate your estimated total monthly operating costs. You will be provided with:

- Break-even targets. These are how much you have to make daily, weekly, monthly, and yearly to cover your shop’s costs. If you’re trending below these numbers, you are off track.

- Profit targets. These are how much you have to make daily, weekly, monthly, and yearly to cover your shop’s costs and meet your defined profit percentage. If you’re trending at or above these numbers, you are on track.

From there, these break-even and target numbers are used to calculate several values which factor into your price matrix.

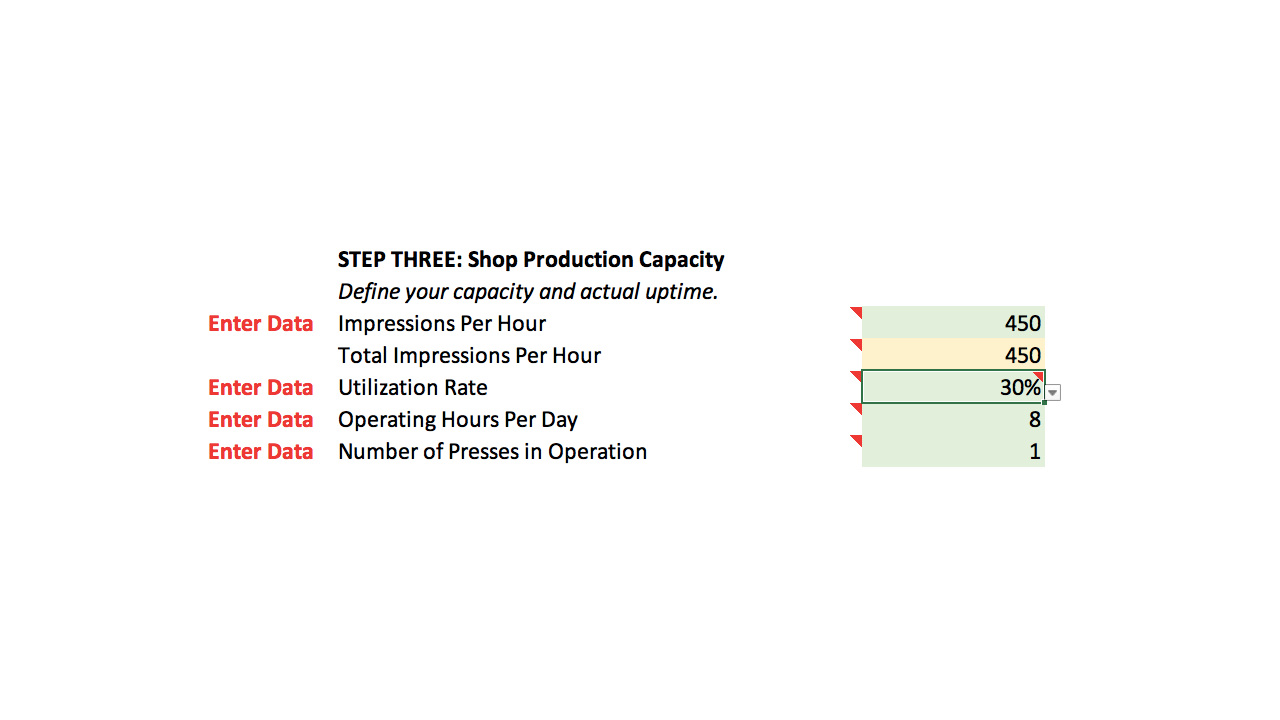

Step 3: Input your shop’s estimated production capacity

Let’s be transparent: this is where things get a little bit more challenging. Let’s dive in to each area separately and help you understand what values to input.

Here’s what you need to know:

- Impressions per hour. This is an estimate of your production capacity. Don’t think of this as how many shirts you can print in an hour, think of this as how many times you do an impression (in other words: dragging the squeegee across the screen).

- Automatic presses are capable of 1080 pieces an hour, but it’s far more likely that your shop operates between 300 and 600 impressions per hour.

- Manual press operators often operate between 80 to 150 impressions per hour.

- Tip: calculate the number of impressions for a job, and then time how long printing takes. Do this repeatedly to get an estimate for how many impressions per hour are likely in your shop.

- Tip: use a lower value than you may actually be capable of to ensure you are compensated fairly.

- Total impressions per hour. Unless you are planning on operating more than one press for this job, you don’t need to alter this field. If you are using one press for the job, this value should be the same as your impressions per hour.

- Tip: to change this value, alter the Number of Presses in Operation cell. It will simply multiply the number of impressions per hour by the number of presses.

- Utilization rate. This is the most important metric in the spreadsheet. Your shop’s utilization rate is the percentage of time your presses are actually printing. We have discussed shop utilization with dozens of shop owners and industry consultants and found that shop utilization tends to be no greater than 40% (and, typically, is much closer to 20-30%).

- Tip: if you’re unsure of your utilization rate, we suggest a default rate of 30%.

- Tip: estimate your utilization by measuring how much of each day at your shop is actually spent printing.

- Tip: utilization will almost never be higher than 50%. We have given you more options but we strongly suggest keeping your utilization around 10% lower than you believe it actually is.

- Operating hours per day. This is how many hours your shop is in operation per day.

- Number of presses in operation. This is NOT how many presses are in your shop. This is how many presses will be in use for this particular job. Typically, this should just be left as “1.” Changing this value will alter the “Total impressions per hour” cell and affect your pricing.

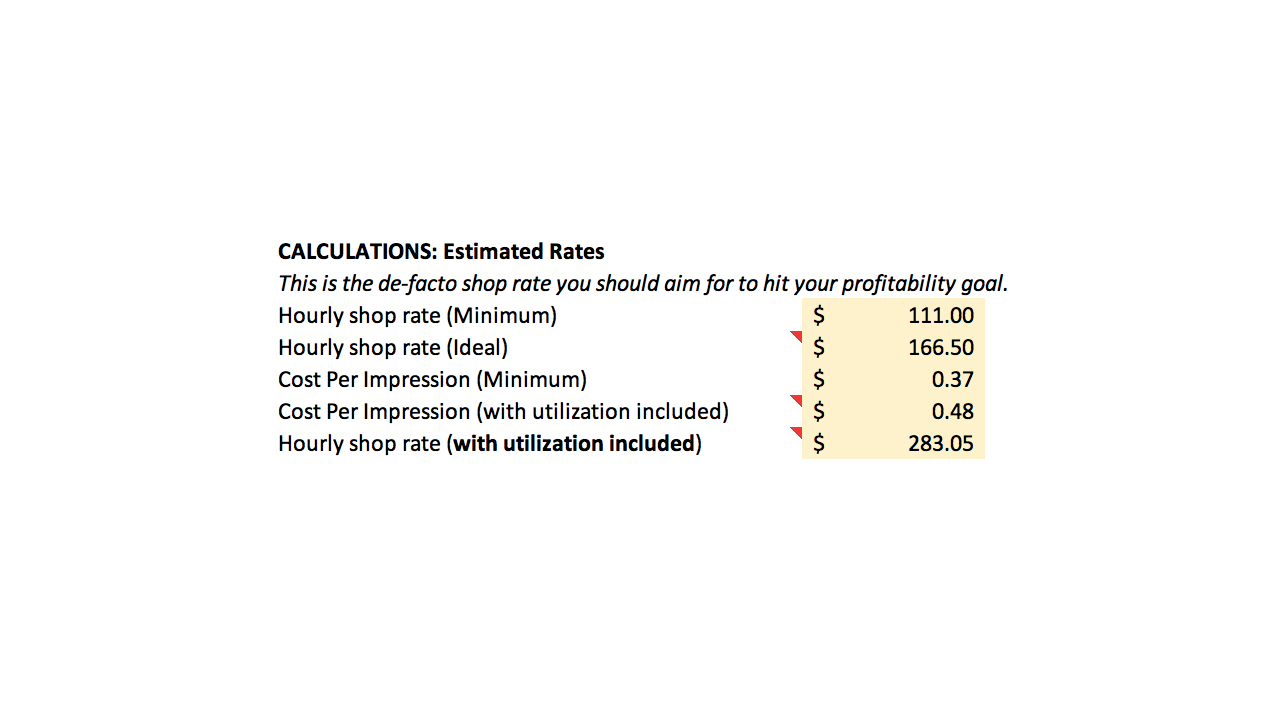

Gaining insights: cost per impression, hourly shop rates, target revenues

With the info provided, we can create simple metrics to judge your shop’s performance and gain a high-level overview . The image above shows several interesting calculations:

-

- Hourly shop rates. You are shown a minimum hourly shop rate, an ideal hourly shop rate and (most importantly) hourly shop rate with utilization included.

- Minimum hourly shop rate is the amount, per operating hour, that you need to hit to pay your bills.

- Ideal hourly shop rate is the amount, per operating hour, that you need to hit to pay your bills and achieve your profitability goals.

- Hourly shop rate (with utilization included) is the amount, per operating hour, that you need to hit to get to your profitability goals when your actual shop utilization is factored in.

- Hourly shop rates. You are shown a minimum hourly shop rate, an ideal hourly shop rate and (most importantly) hourly shop rate with utilization included.

Tip: these values may seem higher than you anticipate. It is worth examining how utilization plays into your shop’s hourly rate: as utilization goes up, your hourly rate goes down (you’re more efficient per hour).

-

- Cost per impression. This is an estimated cost per impression. You’re provided with two different numbers, but only one is used in the pricing matrix calculation.

- Cost per impression (minimum) is simply the Hourly shop rate (Ideal) amount divided by your Impressions per hour. This is not used for calculations.

- Cost per impression (with utilization included) is calculated the same way but includes a markup equal to your utilization rate. For example, if your utilization is 30% and your cost per impression is $0.50, this cell will populate as 30% of $0.50 ($0.15) plus $0.50 for a total of $0.65. This cell is used for calculating the price matrix.

- Cost per impression. This is an estimated cost per impression. You’re provided with two different numbers, but only one is used in the pricing matrix calculation.

Now here’s where the data gets interesting: we’ve broken down your costs into yearly, monthly, weekly, and daily (5 day work week) targets.

These numbers capture what you need to take in to cover your costs (break-even targets) and also provide a high-level target revenue to match your desired profitability.

These are highly idealized values, but they can still be useful as a benchmark to check against. You can do basic back-of-the-envelope calculations about how long a job will take and compare the price to your revenue targets. This could help you know whether to take a job, raise or lower the price of a quote, or subcontract a money-losing job.

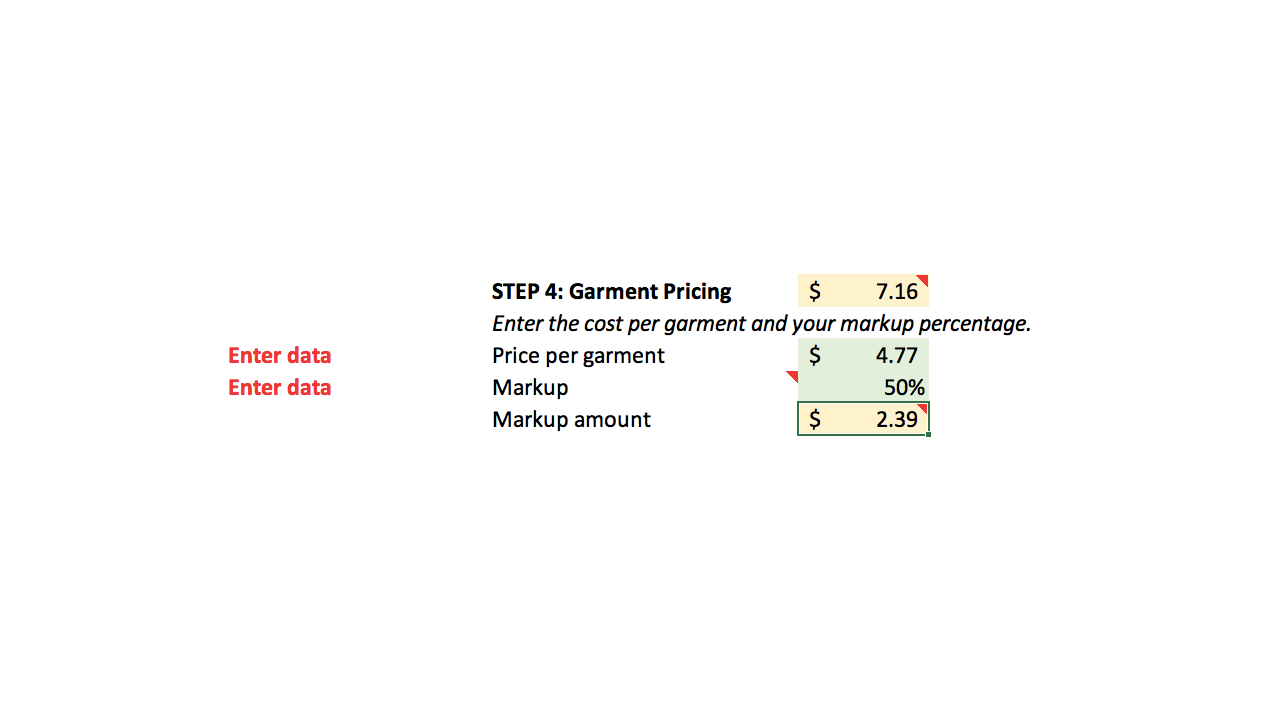

Step 4: Garment Pricing

For each specific job, you’ll need to enter the price of each garment. This is the foundation of your pricing.

“How do I know what to charge as a markup?” You can choose a percentage markup from the drop-down menu. It will calculate the specific dollar amount and display it beneath the drop-down menu. Ultimately, the markup you charge is based on your judgment.

Note: the price per garment that’s displayed in your pricing matrix will never fall below the yellow “Garment Pricing” amount (here, $7.16).

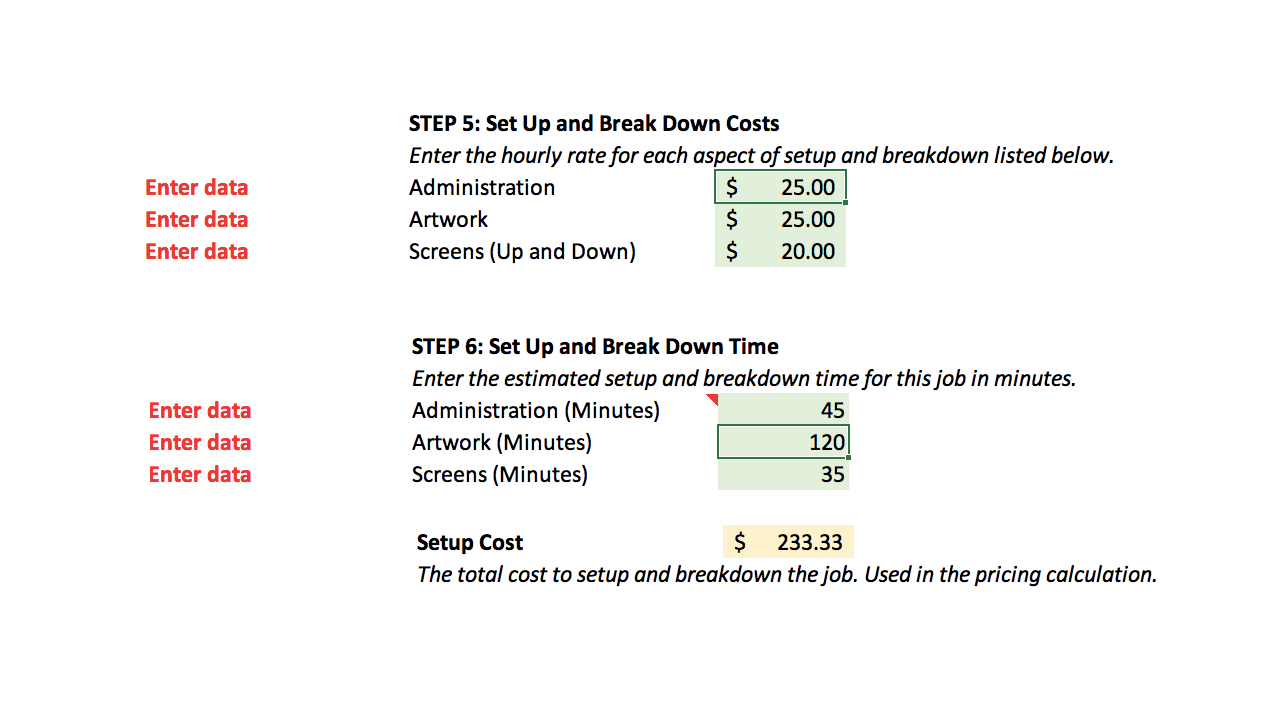

Steps 5 and 6: Set up and break down (pre and post-press costs)

We consider set-up and break-down to be comprised of three primary elements:

- Administration. This is the time and effort expended to get the job into the shop. It could include sales, gathering information, getting approvals, ordering garments, etc. – anything that is required to administer the job and get it on press.

- Artwork. This is the time and effort spent on crafting custom artwork.

- Screen time. This is the time and effort spent on:

- Burning screens

- Reclaiming screens

- Setting up screens on press

- Any other printing-related non-printing labor

Determining your set-up and break-down cost is simple:

- Enter the hourly rate for each department. Sum the cost of labor for that department on a given hour of work (i.e. two people at $15 an hour = $30)

- Enter an estimated amount of time (in minutes) to be spent on the job. While you may not have a clear picture of exactly how long it will take to set-up and break-down a job, this is a great way to estimate the the cost of pre-and-post press activity.

Tip: If we haven’t accounted for some element of your set-up and break-down process, we suggest adding additional time under the Administration section.

Step 7: Generating and modifying pricing matrices

Once you’ve entered data, your price matrix will automatically generate in the “Step 3 – Matrix” tab (no need to do anything but enter your data – the spreadsheet updates in real time).

Some things to notice:

- It should be obvious why screen printing shops have minimum order sizes. It’s simply not reasonable to do small orders given the costs involved.

- You can modify the quantity that the matrix displays to your liking. Feel free to change the green quantity values to anything you like. It may be helpful to use dozens, but for a very accurate picture you can replace dozens with single garments.

- You can modify the number of screens to your liking. Each “screen” is simply an impression. If you need to add more colors, go for it!

Tip: since this is a simplified pricing model, you can add ~1-5 “colors” as an additional print location, or add 1-2 colors to represent flashing.

A spreadsheet never replaces your good judgment and hands-on knowledge of your shop.

We hope this helps your screen printing quotes become more accurate and profitable.

But we think this can give you a boost. With this tool, you can start to examine the relationship that pricing has in relation to your shop’s productivity, your shop’s costs, and your revenue goals.

We will continue to update and improve this tool as time goes on. We really want your feedback, so don’t hesitate to let us know what you think! We owe thanks to Andrea Harmon from Idaho Shirt Stack for her corrections and feedback – and we want yours!

Good Pricing Takes Time, Testing & Patience To Get Right

With thousands of SKUs, products, decoration methods and variables to control, it’s no wonder that pricing is the single most common question in the garment decoration industry.

Want to start pricing your jobs correctly? Develop one pricing calculator based on your best guesses, then compare it to jobs you’ve already done. Are you close to your target, or way off base?

Once you’ve implemented a price matrix, keep checking up on it. Are you still profitable? Are your customers still happy? Revise your prices quarterly!

Creating a clear system for pricing your jobs makes running your shop simpler and more profitable.

Conclusion: Ask Us Questions

Ask us questions about pricing!

It’s easier to get specific when we know the details – this is a general guide for what to consider before making your price matrices, not a plug-and-chug equation you can jot down and use later.

It’s just not that simple!

We’re always tweaking and updating our price matrices at Campus Ink – and Printavo has our back thanks to their simple screen printing management software.

So to sum up what we’ve covered about screen printing pricing:

- Calculate the right markup for your garments

- Know exactly what the job requires before you send the quote

- Price in difficulty & complexity

- Give discounts when appropriate – they’re worth it

- Price for your business situation, not your competition’s

- Experiment, test, refine & continuously improve your pricing

You’ve got this!

Image: Morningstar Screen Printing

I am looking for the link for the Screen Printing Price Matrix and I don’t see it. Is it still available?