DTG shop management software is crucial for success in the competitive direct-to-garment printing industry.

Whether you need to organize your printing process, finalize quotes and invoices, track jobs through your workflow, collect payment, or communicate with customers – organizing your growing DTG business requires an investment in industry-specific software.

I started Printavo because I owned a custom apparel business in college. We found it was impossible to organize everything we needed in one place. We had nearly a dozen different pieces of software for each part of our business:

- Quickbooks for payments and invoices

- Gmail for email and customer communication

- Google Calendar to keep track of due dates

- Quotes and art approvals were just PDFs we edited every time

- Online stores were just not an option

- Paper for order intake (we lost some customers by losing these)

None of this kept us together very well. We burned some important clients early on and learned very expensive and painful lessons about missing deadlines. Amazingly, the same stubborn issues seem to persist for t-shirt printers even years later.

So while I juggled school, trying to grow a small business, and organize a dozen different complicated moving parts I realized: there really needs to be some simple and effective software to help manage custom apparel shops.

Enter Printavo. After years of growth, development, and iteration, there are now several thousand print shops all across the world running and growing their business on our platform.

Why you need DTG shop management software

“The problem starts when your sales in a day become more than you can actually print in a day”

Direct-to-garment printing is going to grow exponentially in the coming decade. The shift toward business models that utilize DTG’s best properties – ease, flexibility, and quick turnaround – has already happened. Major industry players like M&R and Ryonet are urging DTG businesses to invest in technology to print better t-shirts, faster, for more customers.

But if you invest in equipment to print more t-shirts, reach more customers, and grow your business without investing in software to manage your business, you’ll quickly reach task saturation. You can’t grow a business when you’re too busy solving the closest problem.

You’ll work longer, but get less done. You may grow your shop’s revenue, but you likely won’t grow your actual margins and profits.

Businesses like Terminus Tees, Legacy Merch, Merch Monster, Superior Ink and dozens more have organized their DTG printing operations with Printavo. The reason? DTG printing is complicated, and we’ve built a super simple way to keep track of everything you need.

12 practical tips for organizing your DTG shop

We’re constantly talking to, visiting, and getting feedback from Print Hustlers across the world.

Fortunately, our tight-knit community is always looking to help each other grow and improve. Here are some of the best insights we’ve learned as we’ve talked to shops of all sizes and at all stages of growth – from multimillion dollar contract printers to one-man print shops.

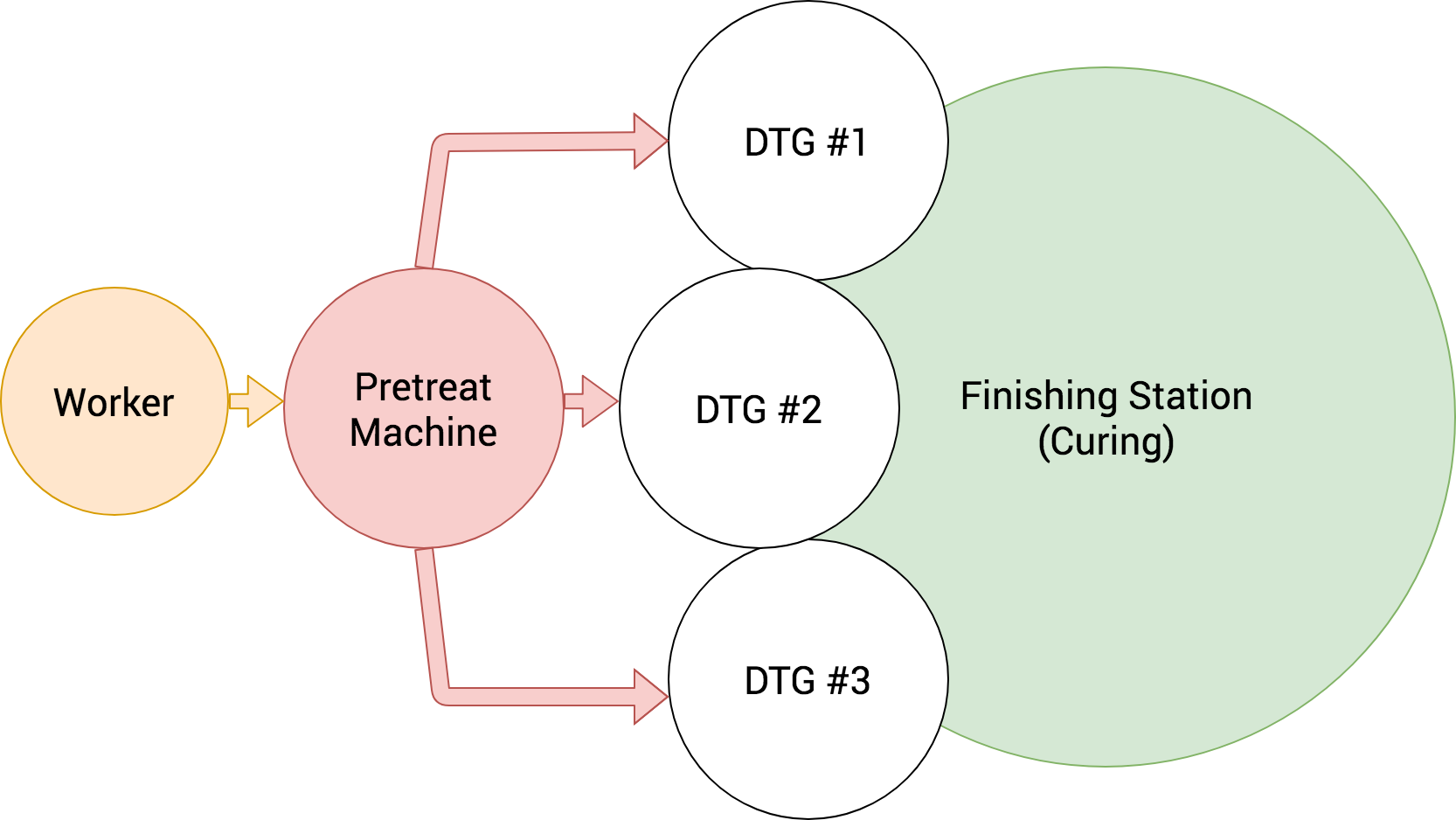

1. Use a pod-based model

The pod-based model is a foolproof way to be more productive in your shop.

While many screen printers utilize a similar arrangement, the pod setup for DTG printing is extremely effective at streamlining your operations. The reason is that it physically institutes your process. Here’s how this would play out:

A worker pre-treats one shirt while another shirt prints. They’ll typically have 3 DTG printers they’re responsible for, with 1 or 2 printing at a time while shirts are pre-treated. As the shirts come off the printer, they’re fed to a curing oven and cured. Learn more about the pod-based model in this interview.

2. Schedule maintenance

The old adage is “If you don’t schedule maintenance for your machines, they will schedule it for you – exactly when you can’t afford it.”

This holds true for DTG printing. If you want to avoid downtime, prevent printing errors, lower your costs, and improve your print quality in the long run you must schedule and perform regular maintenance on your DTG printers.

Most DTG manufacturers supply a robust maintenance schedule, including daily, weekly, and monthly tasks. We suggest keeping these maintenance logs in a public place, having employees sign off on maintenance, and devoting at least 15 minutes every single day to cleaning and general upkeep of your machines.

Much like Starbucks employees have a scheduled 15-minute period for restocking, cleaning, and general upkeep – devote a small portion of each day to keeping your machines in top condition.

3. Standardize your operations

Standard operating procedures are the single most valuable organizational tool DTG shops have. Why? Because they ensure everyone does the job the same way, every time.

While it may not seem necessary, a clearly documented Standard Operating Procedure manual that walks through each and every scenario in your shop is worth its weight in gold. If you have two employees that do the same task in two totally different ways, there’s likely waste, redundancy, or (worst of all) highly variable quality occurring.

Some tips for standardizing your operations include:

- Crafting a public workflow. Go through the steps a job takes in your shop. Document it with LucidChart or Draw.io and post it publicly in your shop.

- Defining exactly which jobs are printed. If you do DTG and screen printing, clearly define when a job is DTG printed versus screen printed.

- Integrate up and downstream. Work hard to identify places where jobs are passed between people and streamline how information is passed along.

- Define what happens when things don’t go according to plan. Misprints, bad art, slow approvals – examine your the edges of your process and create a defined path that workers follow when something goes wrong.

- Clear terms and conditions. Write and iterate on your terms and conditions. Define everything clearly for customers, and use that as the “why” for your standards.

- Create stop-gaps and check points. There should be a series of checks, stops, and sign-offs at crucial stages when jobs are handed off from one person to another.

Learn more about how to craft standard operating procedures here.

4. Look carefully at your RIP software

RIP software (raster image processing software) is essential for getting great prints from your DTG machine. We’ve discovered that many manufacturers provide RIP software that is adequate – but not great.

Why does RIP software matter? It’s how the artwork you’re going to print is translated into a language that your DTG printer can understand. Essentially, RIP software issues instructions to your printer for how to print the image. The print is only as good as your RIP software’s ability to translate it.

RIP software can also lower your overall print costs. Since DTG ink is expensive, you want RIP software that will:

- Minimize the amount of white ink you need to print. For DTG printing, white ink is the most expensive and challenging to deal with.

- Offer high detail. Better RIP software yields higher detail.

- Give good color saturation without using too much ink. Good RIP software will print more vibrant colors without just using more ink.

- Minimize artwork adjustments. A high-quality RIP software will reduce touchups and adjustments before printing.

5. Nail your pre-treatment process

Since DTG printing typically requires pre-treatment, we need to factor in the time, cost, and labor necessary to pre-treat t-shirts before DTG printing. That also means we need to be process-oriented and consider how we can integrate pre-treatment into our day-to-day DTG printing activities.

Bolt-down your pre-treatment process so that it’s perfect. This means defining and documenting:

- Who pre-treats

- How much pre-treat is used

- How to use pre-treat machine (if applicable)

- When t-shirts are pre-treated

- Where pre-treated shirts are stored

- When and how pre-treat chemicals are handled, stored, and distributed

We’ve found that pre-treatment is often left as an afterthought in DTG shops. But pre-treatment is expensive, time-consuming, and mission-critical. Take the time to get it absolutely right!

6. Carefully monitor humidity and temperature in your shop

While this may seem obvious (or not!), you’ll need to maintain an ideal environment for your DTG printer. Keep your DTG shop’s humidity around 40% and the temperature between 65 and 75 degrees Fahrenheit (obviously, follow your equipment manufacturer’s recommendations).

If you run a DTG printer in an open shop in the middle of the summer in Texas, you’ll encounter issues with the print heads. The ink with coagulate in the print heads, the machine will wear faster, and your print quality will suffer (if you’re able to print at all).

Because of this, you should always keep a temperature and humidity monitor near your DTG machines – preferably directly on them!

While this doesn’t seem like something that will keep you organized, it is another part of maintenance that prevents downtime. You may need to invest in a humidifier or an A/C unit – we’ve often seen DTG machines kept in their own small rooms that are carefully climate controlled. This is just a reality when we’re dealing with high-tech digital equipment: it must be taken care of.

7. Focus on your niche(s)

“The riches are in the niches” – print industry expert and consultant Mark Coudray.

DTG printing is great because it lets you print low-volume custom orders at a price that most customers can afford. It also lets you do small rush orders and access the premium on-demand printing market.

A single screen printed shirt makes no financial sense – but a single DTG shirt is absolutely possible. This means you have the luxury of being able to focus on extremely small and specific niches. We’ve seen businesses focus on selling DTG printed baby clothing, harness the latest memes to create viral online stores, and offer ongoing on-demand fulfillment for their clients via DTG printing.

No matter your niche, if you are laser-focused on serving those customers and giving them exactly what they need – your business is far more likely to succeed. Exclusivity means you become an expert on your key customers. Never try to be everything to everyone!

8. Invest in a good power supply

You can’t print anything if your DTG printer is broken. Power surges and outages kill DTG businesses.

After you spend thousands of dollars on your DTG printer and pre-treat machine, shouldn’t you protect that investment against power outages, surges, and other electronic failure?

Luckily, good uninterrupted power supplies (UPS) are not prohibitively expensive. The bare-bones Amazon models cost less than $100, though we recommend purchasing something a bit higher end to protect all of your equipment.

9. Do focused improvement sessions

Here’s one of the coolest tips from our friends at Floodway Print Company in Canada: every two weeks, schedule a 30 minute meeting with your entire team. Give them clipboards, then have them walk through the shop looking for ways to improve it.

You will be surprised what your team finds. Since they’re on the ground every day, they have firsthand knowledge that you don’t (unless you’re a sole operator).

Small, incremental improvements can add up to something much larger over time. This practice of ongoing improvement (called kaizen in the Toyota Production System, a method for eliminating waste and improving processes) is something we do at Printavo with our software – and the same practice can yield huge improvements in your print shop.

10. Create frictionless sales cycles

A “frictionless sales cycle” is a fancy way to say that you:

- Identify a customer’s need or want

- Create a product for that customer

- Put yourself in front of that customer

- Make it extremely easy to purchase your product

Sounds simple, right? But actually designing this, setting it up, and making it work with your production process takes some trial-and-error.

In practical terms, this will likely mean setting up an online store for your customers (we recommend Printavo Merch for online stores, since they connect directly to your existing Printavo quoting, invoicing, and workflow management platform). Then, you’ll load your artwork into your RIP software. As orders come in, you’ll simply print and fulfill them.

DTG is wildly powerful because it lets you seize on memes, viral content, holidays and much more. T-shirts are the ideal e-commerce product: packable, lightweight, customizable, and inexpensive.

But the step before the printing is what’s crucial: you must define your audience, define what they want, and figure out how to market to them. As a side note: we’ve covered marketing your print shop extensively before.

11. Avoid used DTG equipment

While used screen printing equipment is a totally viable way to get started, used DTG equipment is much more of a crapshoot than used screen printing equipment.

You want to avoid used DTG printing equipment for two primary reasons:

- Most used DTG gear is not under warranty

- Yes, you may be able to transfer the machine’s warranty – but that’s unusual. If anything goes wrong, you’re out the cost of the machine and likely can’t get it repaired.

- You have no way to know whether the machine’s maintenance was kept up with

- Just because there’s a maintenance log doesn’t mean the maintenance was actually done.

That said, if you’re a digital printing engineer – maybe you can make a good business out of refurbishing DTG equipment. Otherwise, stick to printing t-shirts and honing your sales and marketing skills. Time spent repairing your DTG printer is lost time.

12. Organize yourself out of the business

This is the #1 piece of advice for entrepreneurs in the t-shirt business: set up your business so that you don’t have to be there.

If you are the center of the business, it’s time to develop systems, strategies, and workflows that don’t involve you and don’t require your input. While entrepreneurs love to play the superhero, work long hours, and take on more than they can realistically handle…that is not a sustainable course. You will either burnout from stress or lose customers and opportunities because you’re focused on the wrong, lower-value tasks.

Your time, energy, and focus are limited. Spend your time on the most valuable tasks that will help you grow your business. That means starting to work yourself out of the business as early as possible.

Here’s the goal: you should be able to leave the shop for a week or more and know, with complete certainty, that every eventuality is planned for and everyone knows what they should be doing. It’s not impossible.

Managing a growing DTG business: process comes first

In a fast moving DTG shop, being able to quickly ship and track your orders is essential. Once you’ve nailed your prints, you have to nail your process – and that’s where we come in. Lots of entrepreneurs enter the DTG business thinking it’s push-button simple. While that may be the case for the actual printing, you still to organize multiple moving parts to be successful with DTG printing.

From garments to art files, Printavo’s simple platform keeps your business organized. You’ll always know what to do next. We’re already in thousands of shops across the world, helping them streamline their processes and focus on their business instead of the closest task. Our three-pronged mission – product, support, and education – is based on our long-term goal to arm print shops with the tools, resources, and knowledge they need to succeed.

Did you know? We’ve seen print shops save more than $35,000 a year by fully implementing Printavo’s efficient shop management system. What could you do with $35,000?

Join Printavo’s amazing community at PrintHustlers Conf 2020, an elite conference for the best and brightest in the custom apparel industry. Now in its fourth year, PrintHustlers Conf has brought shops from across the world (even Nigeria!) for two days of incredible presentations, seminars, and relationship building.

If you want to meet the industry’s biggest players, learn from the best, and have a blast at an incredible venue with truly inspiring people, then Printavo’s 2020 PrintHustlers Conf is where you want to be.

Where: Ace Hotel in Chicago

When: July 24-25, just after the ASI Chicago show.

What: A gathering of the industry’s finest for candid discussions and solution building (and some fun, too)

Curious to see what PrintHustlers Conf is like? Check out PrintHustlers Conf 2019 on YouTube with last year’s presentations and breakout sessions or read our in-depth recap of PrintHustlers 2019. Also, a huge thanks to M&R for sponsoring 2019’s PrintHustlers!

Tickets are selling faster this year than they were last year. We sold out nearly 45 days before the conference last year.

Reserve your space and get more info here.

But you don’t have to take our word for it. Here’s what they told us last year:

“Printavo’s PrintHustlers Conf is the best event we have attended for the last 2 years. The speakers have been great and have helped us in so many areas. We also appreciate the connections that we have made through this conference. It is obvious from attending that this event is not designed to make money off of those attending, but is truly an event created to help us and improve our industry. Printavo is really making a difference in our industry. Keep it up!”

0 Comments