Contents

- What’s the difference between DTG and screen printing?

- Why use DTG instead of screen printing?

- What are the cons of DTG printing?

- Why would a print shop do DTG printing?

- Should you use DTG or screen printing? How do you decide?

- What is “pretreating” for DTG printing?

- How much does it cost to print a shirt with a DTG printer?

- How much does a DTG printer cost?

- How much does DTG printing ink cost?

- Who makes DTG printers?

- How does DTG feel compared to screen printing?

- How much does DTG printing cost compared to screen printing?

- Is DTG printing better than screen printing?

- Conclusion: DTG vs. screen printing

Screen printing and DTG (direct-to-garment) printing are two of the most common ways to print custom t-shirts.

Both printing methods have pros and cons.

So how do you choose between screen printing and DTG printing?

Steven Farag from Campus Ink in Champaign, IL showed us the difference between DTG and screen printing:

Let’s start with the absolute basics.

What’s the difference between DTG and screen printing?

Screen printing is the affordable way to print hundreds of shirts. DTG printing is the affordable way to print a few shirts.

Screen printing

A tried-and-true method for printing ink on textiles, garments, and a variety of substrates, screen printing is a labor intensive process designed to quickly produce hundreds (if not thousands) of prints very quickly.

The screen printing process starts with a nylon mesh screen with light-sensitive emulsion applied to it.

A negative image is printed (typically onto transparent film), then “burned” into the emulsion with a powerful light. The emulsion cures (or hardens), but the negative image remains as a water-soluble paste. This creates a hardened stencil. A screen printing technician then washes out the negative image, leaving openings in the mesh for ink to pass through.

The screen is placed on a screen printing press and registered so it will properly align on the printing surface (typically, a t-shirt). Ink is pressed through the openings in the stencil with a squeegee, directly applying ink onto the printing surface.

Then, the print is typically cured in a heated dryer – for plastisol, the most common screen printing ink, it’s heated to 320 degrees F (though there are dozens of other types of screen printing inks). This curing process makes the ink extremely durable.

Direct-to-garment printing (DTG)

A newer method that utilizes a digital print head to print designs directly onto different surfaces, DTG printing is in a rapid growth phase.

DTG printers are functionally similar to the typical inkjet printer you’d find in a home or office. The process is fundamentally the same: an image is digitized by the printer and then printed directly onto the t-shirt or garment. Ink is sprayed onto the surface by carefully controlled print heads.

DTG printing inks also require curing (like screen printing inks) to permanently adhere. Most DTG printing shops use a curing dryer or heat press to cure their products.

DTG printers range from small desktop sized models to units that require large climate-controlled garages.

Many envision a future where customers order online and a DTG printer automatically prints the shirt. While many businesses have attempted this, the technical and labor challenges have proven tremendous (even for Amazon). DTG printing is not as simple as pushing a button – there are many variables and factors to consider.

You can use screen printing management software like Printavo to do DTG or screen printing – in fact, Printavo works great for any type of custom printing.

Why use DTG instead of screen printing?

Screen printing presses can print shirts quickly – sometimes up to 1,080 pieces an hour!

However, a screen printer’s setup time limits what’s possible. Screen printers can print one design at high volume quickly. But if they need to print multiple designs, or do just a few prints, screen printing can be prohibitively expensive compared to DTG printing.

Here’s why: the extensive labor required to create, separate, coat, expose, and register screens makes the screen printing process inefficient for small quantity orders with lots of colors.

Let’s say you want 20 t-shirts. A 4-color design usually requires 5 different screens to print (since you need an underbase screen).

It takes much more time to create those 5 screens and set them up on the screen printing press than it does to actually print the 20 shirts!

For small (12 pieces or less) orders with lots of colors, DTG printing is a great fit.

IMPORTANT DIFFERENCE: Screens and setup make screen printing too expensive for low-quantity custom orders.

What are the cons of DTG printing?

Answer: It may sound like DTG is a futuristic answer for printing everything under the sun. Should you buy a DTG printer? The answer isn’t so simple.

DTG technology improves by leaps and bounds with each passing year. Regardless, DTG has several important downsides to consider.

It’s expensive

DTG printing is not cheap.

The ink is expensive. The actual equipment is expensive. Maintenance and R&D are expensive.

It can cost $4 (or more!) in ink and pre-treat alone to do a colorful print on a dark shirt.

Additionally, DTG printing is labor intensive.

“We hire screen printers to run our DTG machines, since it takes a certain set of skills,” says Stoked On Printing’s Kevin Oakley.

You must meticulously maintain your DTG printers. They are not maintenance-free machines – and DTG printing is NOT a “push button” printing style.

Another problem? There are no “mid-level” DTG printers. The market is essentially low-end DTG printers and extremely high-end DTG printers. (Manufacturers, take note!)

It’s slow

DTG printers cannot keep pace with screen printers. They print line-by-line – just like a printer at your house.

With most DTG printers, you can print roughly one shirt every two minutes.

Amazon tried to overcome this speed issue via scaling – they bought thousands of Kornit DTG printers – but their Merch by Amazon fulfillment business is still not fully operational after more than three years of development.

This is why screen printing is still a strong option for custom garments: it’s simply much faster than DTG printing once you overcome setup time.

By 72 prints, screen printing absolutely blows away DTG printing for efficiency.

The print won’t last as long

Yes, it’s true, DTG prints typically aren’t as durable as screen prints.

Because of the ink that DTG printers use and the way that the ink is applied, the end customer will eventually see the print fade significantly from repeated washing and drying.

Some industry estimates say that DTG prints on garments last anywhere from 25% to 50% as long as screen prints.

This doesn’t mean DTG printing is inferior. After all, screen prints can survive hundreds of wash cycles if they’re cured and applied correctly. DTG prints can still survive 50+ washes and be acceptable to the customer – certainly “good enough” for most customers!

The bottom line about quality: DTG prints are typically made for customers that have different demands than customers that place high-volume screen print orders. DTG prints aren’t ideal for something like uniforms – but they’re perfect for a unique souvenir.

Garments require pretreating

View this post on Instagram

Want to use DTG to get vibrant colors, to print with white ink, or to print on a dark t-shirt? You’ll need to pre-treat your shirts.

Pre-treating adds another minute of time to each garment you print.

Most shops apply pre-treat with a roller or pre-treat machine. Pre-treat chemicals cost slightly less than DTG ink but are still a considerable expense.

Unfortunately, it’s not recommended to pre-treat large numbers of garments ahead of time. Over time, the pre-treat may degrade – meaning the ink won’t adhere to the garment. This means most shops pre-treat each shirt individually just before it’s printed.

A rule of thumb: if you’re printing white inks with a DTG printer, you must pre-treat your garments.

The exception here is a hybrid printing system like the M&R Digital Squeegee or one of ROQ’s ROQhybrid systems.

Why would a print shop do DTG printing?

DTG printing lets screen print shops take smaller, more complex orders that they would normally turn away.

Print shops use DTG printers for specific applications – but the most common is simply printing 1 to 12 shirts for customers that only need a handful of shirts. However, there are still multiple contexts where DTG printing makes a lot of sense.

Complex (or…bad) artwork

DTG printing is often ideal for art that isn’t great for screen printing.

Since you don’t have to separate or burn screens, screen printers are able to use DTG printing on art that simply doesn’t translate well to the screen printing press.

You can print full-color photographs and other challenging high-color-count art with DTG printing easily.

Small orders

Since screen printing typically isn’t profitable at small volumes, DTG printing offers a reasonable alternative for customers that want fewer than 12 pieces.

The most frequent orders in many print shops are fewer than 72 pieces! Every print shop has had someone walk in and get frustrated that they can’t simply order one t-shirt.

If you build a business model that can accommodate small orders, DTG printing can be highly profitable and effective.

But if you only have a handful of small orders, you may be better off utilizing contract printing instead of investing in DTG printing. There are multiple print shops that specialize in small orders – it’s their bread-and-butter.

Rush orders and reprints

Rush orders – such as someone needing a few shirts within 24 hours – are a great use for DTG printing. You can fire up the printer, pre-treat shirts, and send them off after printing & curing very quickly in a pinch.

Other rush orders could be replacements or reprints. Perhaps a single shirt is missing from an order, a print was botched, or some other error occurred. You can simply fire off a shirt and send it out without remaking screens.

Another use? Maybe a customer ordered 100 shirts last year, but now they just want 5 of the same design. DTG printing is perfect for that kind of small order.

This kind of DTG printing is a premium service – so charge appropriately for rush orders, replacements, and reprints.

Should you use DTG or screen printing? How do you decide?

Choosing between DTG printing and screen printing isn’t so difficult if you know the specifications of the order.

There’s a simple way to determine whether you should screen print or use DTG for an order!

No, you don’t need to create a checklist for each order – you can simply look at the artwork and your shop’s capabilities.

Is the artwork better for DTG or screen printing?

First, consider what it will take to screen print the artwork that the customer has.

If you see that artwork can easily be separated, lean toward screen printing. It’s still the first and best way to print a shirt.

If the art is a photograph, lean toward DTG printing.

While many printers are totally adept at CMYK full-color printing, setting up and executing a CMYK print may not be your strong suit. You may need to print many test prints to achieve the look you want. And many customers will not accept the variance that CMYK prints have.

Unless you specialize in printing complex art, lean toward DTG for things like photographs (unless the customer is requesting a large quantity).

Can you subcontract the job?

There is always a print shop that has more experience than you do. Many print shops specialize in small run DTG printing, complex art for screen printing, and making difficult prints come to life.

Remember, the goal is to add value by meeting your customer’s needs! Don’t use a customer’s order to learn a new way to print.

If the customer wants a high-quantity print with complex art, you don’t want to sacrifice quality. Consider using a contract printer the job to a print shop that specializes in complex simulated process screen printing (or trying to separate and print it yourself).

Note: if you’re a customer looking to purchase custom t-shirts and are looking for more information, you should trust your local print shop’s judgment about how to print your t-shirts. They’re the experts!

What is “pre-treating” for DTG printing?

99% of DTG printed t-shirts need to be pre-treated – so don’t forget about pre-treating!

You will virtually always need to pre-treat garments that:

- Are a dark color like black or navy

- Will have white ink printed on them

Think of pre-treatment for DTG like primer for painting a house.

This coat acts like an underbase so that the ink is vibrant and longer-lasting. Without pre-treating garments, DTG prints appear dull and faded – or worse, don’t adhere to the garment at all.

In most shops, a DTG pre-treat machine applies a special coating to the shirt – though many use rollers to apply pre-treat by hand.

Pre-treatment adds considerable time and cost to DTG printing. This is often a “blind spot” that screen printers encounter when they make the leap to DTG printing.

Pre-treating can take a minute or more. Pre-treat can be expensive (Ryonet sells a 20 liter supply of Epson’s pre-treat for just under $700) – but it’s necessary for professional-quality prints.

How much does it cost to print a shirt with a DTG printer?

There is a major upside to DTG printing.

You can accurately calculate your costs. This makes it much easier to price DTG prints.

Epson and other DTG printing manufacturers offer a robust and accurate cost calculator tool for DTG printers.

So why is it easier to price DTG prints, and how do you do it?

Pricing resources

Your DTG printer applies a given amount of ink over a pre-determined area on a garment. You can actually calculate the exact cost of the ink over the area.

A DTG pricing formula is typically simple: cost of labor + cost of ink and pre-treat over the area printed + cost of garment = total cost.

A large DTG print with 7+ colors on a dark garment can easily cost $8 in ink and pre-treat alone.

So when you’re starting to price your own DTG prints, you should consider the cost of pre-treating, the cost of ink, and how large the image actually is. Luckily, these are all known quantities – which means pricing your DTG prints can be a lot easier than pricing your screen prints.

Some awesome resources to estimate DTG pricing:

- STAHL’s offer a DTG return-on-investment calculator that lets you determine the time to profitability.

- Epson uses a formula similar to their large format cost calculator.

- Luke Ryerkerk from Ryonet has lots of helpful DTG tips in our exclusive interview.

How much does a DTG printer cost?

We will be blunt: DTG printers cost tens of thousands of dollars.

It costs a minimum of $20,000 to $30,000 for a complete and professional DTG printing setup. The most expensive DTG printing setups can easily exceed $250,000 – though higher-end models often include a comprehensive warranty and maintenance package as well.

Because of the high price, we advise print shops to consider purchasing their first DTG printer after they’ve contracted thousands of dollars of DTG prints out of their business.

Put another way: DTG printers – and any custom printing equipment – do not generate demand.

DTG printer, pre-treat machine, and a heat press

At the absolute minimum, you will need a DTG printer, a pre-treat machine, and a heat press to start DTG printing.

Most shops start with a lower-range DTG printer. Expect to spend between $10,000 and $30,000 for a starter DTG machine. Used DTG machines are widely considered a bad idea – you won’t know if the maintenance and upkeep has been performed properly.

A pre-treatment machine typically costs between $3,000 and $4,000. Don’t underestimate the importance of your pre-treatment machine! It’s one of the most important parts of your DTG setup. Lawson, Equipment Zone and M&R all make pre-treatment machines for DTG printing (along with numerous other manufacturers).

Finally, you’ll need a heat press. They can cost $1,000 to $2,000 for a high-end model. However, you can use the heat press for innumerable things in most print shops. Used heat presses are fine – they can be had for hundreds of dollars (if not less).

Low cost: $20,000 and up

Typical Brother or Epson DTG printers start around $10,000. Most models range between $15,000 and $30,000. These are the “desktop” DTG printers that the overwhelming majority of print shops use.

Interestingly, there are currently no “mid-range” DTG printers.

In other words, the DTG market has a robust niche from $10k-$30k – then jumps all the way up to $100k and more. There simply isn’t a mid-range price-point for DTG printers yet. To go up to the next level, you must spend significantly more.

High-end: $100k and up

M&R’s Maverick exemplifies the high-end DTG printer market. Priced around $250,000, the Maverick is part of the growing market for large-scale, industrial DTG applications.

Israel-based Kornit competes in this space, backed by a sizable investment from Amazon’s print-on-demand division. Despite pouring hundreds of millions into the print-on-demand space, Amazon is still not the dominant player in the market. Regardless, Kornit has significantly advanced the entire DTG printing industry from a technological standpoint.

These expensive machines are designed specifically for industrial applications – they can run almost 24/7. But they require carefully controlled temperatures and humidity levels to operate. It’s important to note that it’s unrealistic for most screen printing shops to put a high-end DTG machine in their shop without robust climate control.

What is the best DTG printer on the market?

This is a difficult question to answer. No DTG printer is perfect for every application.

We coach shops to consider their business model when purchasing a DTG machine. If they have built a consistent flow of low-volume orders, DTG printing can be a valuable investment. If they do not have an infrastructure to handle the order intake, printing, and shipping – then DTG can be a bank-breaking headache.

However, the most trusted brands for DTG printing are Brother and Epson for desktop-style DTG printers. For high-end DTG printers, Kornit, ROQ and M&R are considered top-of-the-line.

A word to the wise: buy something nice, or buy something twice.

All of these brands put out high-quality DTG printers – if they’re purchased new. You may find a deal on used DTG equipment, but remember that DTG printers do not hold their resale value like screen printing presses do.

Most experts don’t recommend purchasing used DTG equipment since the maintenance and upkeep are so important (and you have no way to verify if it was done correctly).

Be prepared for additional repairs, costs, maintenance, and troubleshooting if you buy used DTG printers – and beware that you likely won’t benefit from the manufacturer’s warranty!

How much does DTG printing ink cost?

The cost for DTG ink is much higher than the cost for screen printing ink.

While there are a lot of ways to save money on screen printing ink, DTG inks are typically crafted for one specific manufacturer’s printers.

So how much does DTG ink cost? Each DTG ink cartridge costs around $200. For a typical CMYK DTG printer (with two white inks), there may be $1,200 worth of ink in the printer at any given time.

This is known as the “razor and razor blade” model, and it’s the backbone of DTG printing manufacturer’s business model. The DTG printers are not where manufacturers make their profit: the consumables they sell you to support the machine are how these companies turn a profit.

As a kicker, DTG ink has a shelf life. You can’t buy it on sale and save it for later like you can with Plastisol screen printing ink.

Ink alone can cost more than $400 a month to run a DTG machine.

Who makes DTG printers?

There are a handful of major DTG printing manufacturers – with many more waiting in the wings.

An important note: virtually every DTG printing manufacturer utilizes the “razor-razor blade” model – meaning they make the bulk of their income from selling DTG ink, not selling DTG machines – so check ink pricing as well as machine pricing. A higher-cost machine may have lower-cost ink (and vice-versa).

Kornit

Kornit is based in Israel and has been a longtime leader in development and research for direct to garment printing.

Their large DTG printers are priced at a premium but are known for excellent service, warranties, and generally high build quality.

They are focused on developing industrial DTG technology that can scale to meet the needs of print-on-demand companies.

Brother

Brother has made a name for itself in the DTG space with their versatile and powerful GTX line of printers. The GTX printers are notorious for their ability to print on a wide range of textiles.

While Brother focuses primarily on the desktop DTG printing market, some print shops “chain” Brother’s DTG machines together and use them to print large volumes. One shop in Las Vegas purchased nearly a dozen Brother GTX printers to meet their DTG printing needs.

M&R

M&R made the M-LINK line of DTG printers and currently manufactures the EZPREP Pretreatment system. They also have invested heavily into hybrid screen printing, which mixes DTG applications with a screen printed underbase.

Based just outside of Chicago, M&R believes the industry will move toward a print-on-demand model. “The same number of t-shirts will be sold, but how they’re sold and printed will change,” said M&R’s CEO Danny Sweem.

Epson

Epson is famous for their large-format printers, and is a common household name with decades of experience in inkjet printing.

They make an extensive line of DTG printers for a variety of industrial applications. Epson competes with Brother for the lion’s share of the desktop DTG market in the United States. Their products compare favorably to others on the market and are widely considered a top-tier manufacturer.

Ricoh (Anajet)

AnaJet by RICOH is Ricoh’s DTG division. Ricoh is multinational corporation focused on providing digital solutions to businesses. Their print and embroidery division is just one example.

With decades of experience in embroidery technology, Ricoh has begun its acquisition and expansion phase. AnaJet invested heavily in consumer education and ongoing support for their DTG users, making it a good fit for Ricoh’s solutions-oriented business model.

Omniprint

Omniprint is a leader in the DTG space. Their Freejet printers are a desktop option, while they also offer the Cheetah – a large, industrial DTG printer.

Omniprint also offers turnkey business kits for DTG printing – a unique offering in the industry. Their online store makes ordering supplies simple.

Col-Desi

Col-Desi manufactures a variety of DTG printers, including one of the earliest two-platen DTG printers. This allows print shops to print two designs on one printer simultaneously.

They have a litany of offerings and services that span beyond DTG printing – and a formidable support staff armed with lots of educational resources.

China

A number of Chinese manufacturers are also beginning to bring their DTG offerings to market, either directly or by partnering with major brands. These DTG machines are high quality, and many DTG manufacturers source many of their parts from China (then assemble the machines in the US).

We expect that there will be dozens more manufacturers and suppliers for DTG printing in the next 5 years. Chinese manufacturers have a formidable head-start since they have taken the lead in the actual manufacture of DTG printing components.

But no company owns the DTG market yet. There is still tremendous opportunity for a manufacturer to control broad swaths of the custom printing market with the right product – we’re looking forward to mid-range (less than $100k) DTG printers emerging as a viable option.

Remember the software you use to manage your DTG printing business is just as important as your printer. Screen printing management software like Printavo can be used for DTG printing too.

How does DTG feel compared to screen printing?

You can achieve extremely soft screen printed t-shirts with the right tips. Certain screen printing inks and techniques (like discharge inks) create a print that is actually part of the fabric – so you can’t feel it at all.

However, we can generally assume that:

- DTG printed t-shirts may have a softer hand feel than plastisol screen prints

- DTG ink is much thinner than plastisol ink

- DTG printed t-shirts may not have a softer hand feel than water based screen prints

- Water based inks can have zero hand feel

A DTG print will typically be softer than a screen print.

But that isn’t always the case – and DTG printing isn’t always the best way to achieve softer prints.

Remember: DTG prints may not be as durable as screen prints, and may not be appropriate for every type of garment or print. Some customers want “bulletproof” plastisol prints, where there’s a thick layer of ink – while others want zero hand-feel.

How much does DTG printing cost compared to screen printing?

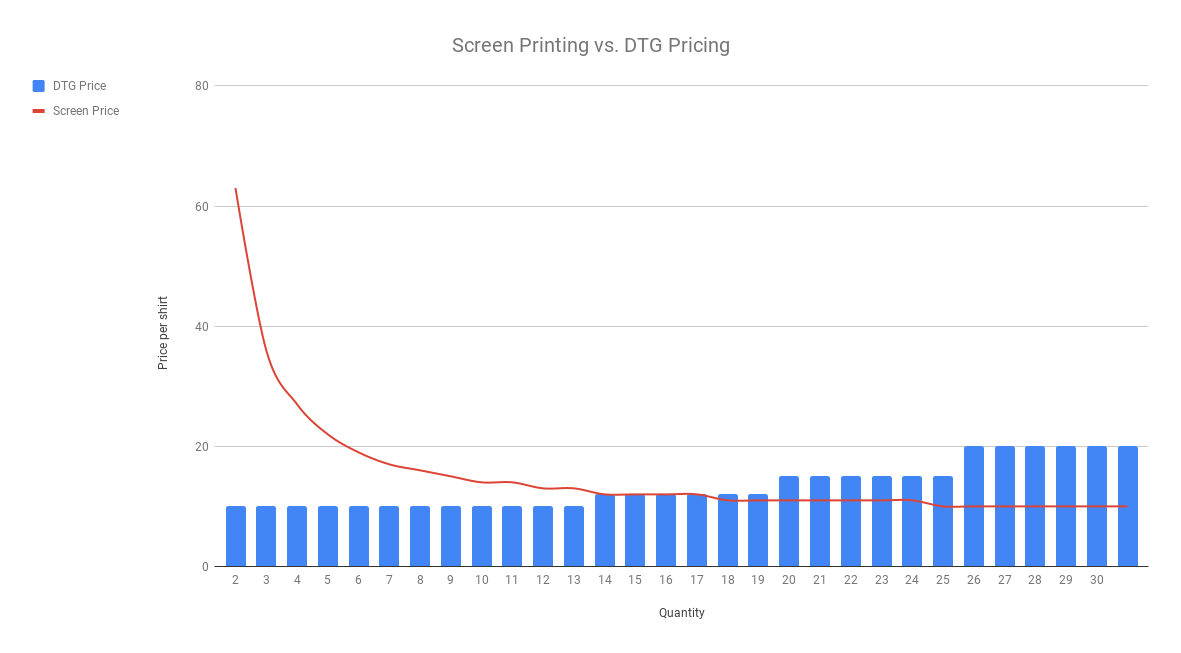

For small orders (less than 24 pieces) DTG printing typically costs less than screen printing.

For large orders (more than 24 pieces) screen printing typically costs less than DTG printing.

Why is this the case?

Screen printing has a lot of setup and breakdown involved. To overcome the cost of creating screens and then setting up those screens on press (as well as breaking down and reclaiming the screens), screen printers need to print a lot of shirts to make the job profitable. This “break-even point” varies, but a common industry minimum is 24 t-shirts. However, screen printing is incredibly efficient at high volumes.

DTG printing is inefficient at high volumes. DTG printing is profitable and easy for 1 to 12 garments. There’s almost no question that a DTG printer will be faster for printing just one shirt. However, once you need more than 24 garments, screen printing becomes exponentially faster and more profitable – while DTG printing stays at the same level of production and profitability.

The graph below shows screen printing prices in red, while DTG prices are in blue. As you can see, screen printing prices are very high – at least initially. However, as the quantity increases, the time and cost to DTG printing increases…while screen printing gets more affordable.

One way to get around this is to do a “pod printing” setup.

Shops that do a lot of DTG printing will daisy-chain their pre-treat machines, DTG machines, and curing dryers to create a “pod.” This means they can print multiple designs at once, or raise their overall capacity to print larger orders. This is what Amazon attempted to do with Kornit (mentioned above), though on a much larger scale.

Learn more about pod DTG printing in our guide to DTG printing with Luke Ryerkerk.

Is DTG printing better than screen printing?

DTG printing and screen printing are both great ways to print t-shirts and other custom garments. So which is better?

Yes, you’ll hear screen printers trash DTG as “direct to garbage” and hear DTG lovers call screen printers old-fashioned. There is definitely some animosity here!

So let’s start with something most people can agree on: screen printing is still the most durable, time-tested, and familiar printing method for custom t-shirts and garments.

DTG printing is another tool for a print shop to meet the needs of their customers. Very few shops are throwing out their screen printing squeegees for inkjet printers!

You could evaluate DTG vs. screen printing according to print quality, speed of production, price, and so on. Different shops have different competencies.

Ultimately, each shop is different.

There are large contract DTG businesses that never do screen prints – and multimillion-dollar screen print shops that would never think of using DTG. Different businesses have different models – some do online store sales, while others make their money on 30,000 piece runs that DTG printers could never keep up with.

For small orders, DTG printing is a great fit. For large orders, screen printing blows DTG printing away. Both methods are a tool for serving customers!

Conclusion: DTG vs. screen printing

Ultimately, there’s no clear winner between DTG and screen printing. There are simply too many variables in the custom apparel industry to say that one decoration style is the best or only way to accomplish the ultimate goal. And what is that ultimate goal? To make your customer’s idea come to life.

We urge anyone considering a new decoration method – whether that’s considering if you should buy a DTG printer or try out screen printing – to worry less about the exact decoration method they use and more about whether they’re printing exactly what the customer wants.

The number one priority is fulfilling your customer’s vision – or connecting them with someone that can.

In screen printing and custom apparel decoration, you are more like a barber than a mass manufacturer. You are responsible for creating a custom experience that reflects the customer’s needs. Become the expert and guide your customers toward decorations and customizations that they’ll love – and that help you turn a profit.

0 Comments