Whether you’re a customer that wants a soft screen print, or a screen printer that wants soft hand prints, here’s how to get softer screen prints.

You can get soft screen printed t-shirts (even with plastisol ink) but there are a few things you should know first.

Let’s define a couple of terms:

- Hand refers to the way a shirt or print feels. “Soft hand” is a way to describe a soft print.

- Plastisol is the most common type of screen printing ink. It’s derived from polyvinyl chloride (PVC) and can last for the lifetime of a t-shirt.

- Fibrillation is when the fibers on a t-shirt appear on the print. Loose fibers on the t-shirt contaminate the ink.

What is soft screen printing?

Have you ever purchased a t-shirt and noticed that the print feels like it almost isn’t there?

Soft screen printed shirts are one of the most popular types of prints. The soft hand feel is what customers are after.

This can be accomplished through different techniques:

- Using a soft t-shirt, like a tri-blend or woven cotton

- Using discharge inks, which dye the fabric itself

- Using special techniques and additives to soften your ink

Can plastisol make soft screen printed t-shirts?

By combining the right fabric and the right ink, plastisol can make soft screen prints.

For soft hand printing, the following brands have superior fabric:

Some of the most popular white plastisol inks include:

- International Coatings 7014 Legacy White ink

- Wilflex Epic Quick White

- Also recommended: Wilflex Epic Bright Tiger

- Rutland Premiere ink

However, you’ll also need to use the thinnest possible mesh, deposit the least amount of ink, and use a roller squeegee to help soften your prints. Additionally, you can add soft hand additives (and curable reducer) to your inks. But that’s only part of the equation.

How do you get a soft screen printed t-shirt?

First, let’s define a couple of terms:

- Hand refers to the way a shirt or print feels. “Soft hand” is a way to describe a soft print.

- Plastisol is the most common type of screen printing ink. It’s derived from polyvinyl chloride (PVC) and can last for the lifetime of a t-shirt.

- Fibrillation is when the fibers on a t-shirt show up as visible debris on the print. This is due to loose fibers on the t-shirt contaminating the ink.

Tip number 1: Print on the right type of shirt

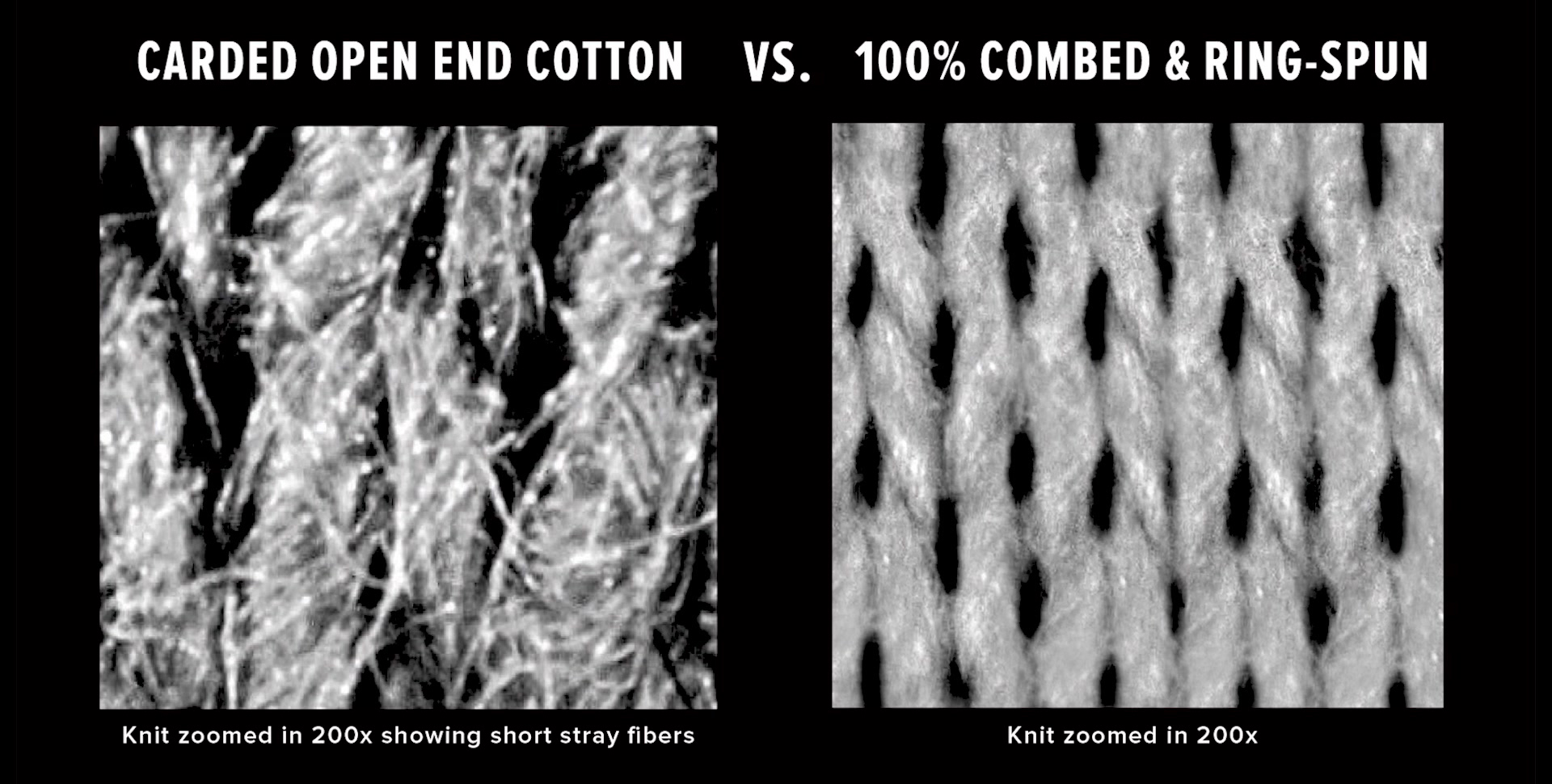

For soft screen prints, you want a ring spun cotton shirt versus a carded open-end cotton shirt.

Ring spun cotton shirts are ideal for screen printing. They retain more detail, are a better printing surface, and are softer to the touch compared to carded open-end cotton shirts.

Why are ring spun shirts better for screen printing?

Cotton t-shirts are nothing more than thousands of thin cotton threads woven together. The composition of that weave – the quality of the fibers, the density of the weave, and the overall uniformity of the fabric – determines whether the t-shirt is great for screen printing (versus merely acceptable).

The “holes” created by the gaps in the shirt’s woven fibers are smaller on a ring-spun shirt because the cotton is woven together tightly. Because of the tighter weave, ink is deposited higher up on the fabric. Since you don’t need to push ink into the shirt, you can deposit less ink – which makes the print feel softer.

The benefits of ring spun cotton are twofold:

- A superior printing surface. The shirt’s surface is smooth and reliable for printing.

- Less ink deposit is required. The printer can use less ink. Less ink makes the print feel softer and lighter.

Higher quality cotton weaves are a screen printer’s favorite!

Though a ring-spun cotton shirt may cost a few extra bucks, the overall quality of the screen print will increase dramatically when you use premium garments. Vibrance, texture, and hand all improve with a better t-shirt.

Whether you’re a customer looking to purchase screen printed shirts or a screen printer yourself, you’ll make more money if you choose a better shirt.

For people to love their t-shirts, offer a higher-quality cotton blank. A good print on a great shirt makes for a lifetime of enjoyment.

Tip number 2: Equipment and ink choice makes a big difference

There are several things that will ensure softer screen prints:

- An automatic screen printing press for consistency over hundreds of prints

- The right screen mesh to capture details but lay down the correct amount of ink

- The least amount of ink on the shirt

Automatic presses can make softer prints

Over hundreds of prints, an automatic screen printing press will provide more consistent results than a manual screen printing press.

That isn’t to say that a manual screen printer can’t make soft hand prints. They can – and do – every day!

However, an automatic press ensures a consistent print across thousands of prints.

Think about it this way: a machine will apply consistent pressure and speed without tiring. A manual printer’s quality will vary no matter how they good they are. That isn’t to say that manual screen printers can’t make soft prints or print hundreds of shirts – manual screen printers produce beautiful work for high-end clients all of the time.

Don’t let a lack of an automatic screen printing press scare you away from any screen print shop!

Thin-thread mesh makes softer prints: less ink is deposited

A screen printer’s screens matter. Not all screens and mesh are made the same! You have to use the correct screens for a softer print: thin-thread mesh screens.

Screen printing screens are nothing more than interwoven nylon mesh threads. The space between these threads – and the thickness of the threads – makes a huge difference in print quality.

There’s two common mesh types in screen printing:

- T-mesh. The threads of this screen’s mesh are thicker.

- Thin-thread mesh. The threads of this screen’s mesh are thinner.

Every screen printer should know the difference!

With t-mesh screens, there are smaller openings for the ink to go through. This is because the threads that make up the screen are thicker.

With thin-thread mesh screens, there are larger openings for the ink to go through. The threads that make up the screen are thin.

What does this mean?

You need more pressure to get the same amount of ink through a t-mesh screen. With thin-thread mesh, you apply less pressure, less ink, and the ink sits higher on the shirt. This makes the print lighter and softer.

Matt has moved exclusively to thin-thread mesh screens because he gets better ink opacity on his customers’ t-shirts with less pressure and less ink deposit. It’s the same result – with less ink on the shirt! T-mesh screens allow for more detail, less ink, softer prints, and less time on press (since there are fewer print strokes required).

Remember: less ink on the shirt means a softer print

To get softer, smoother, and better prints…use less ink. But don’t stop there. You need to use better inks for better results: there are 20 different white inks from every ink manufacturer!

Ask your screen printer what their favorite white ink is. They should know!

Rutland Premiere is Matt’s preferred white plastisol ink for soft prints.

The type of ink will certainly affect the outcome of your print. As always, you should carefully investigate and test print – and ask your supplier for help.

The sales professionals at every major ink manufacturer include highly skilled professionals who have years of experience in print shops. Lean on their knowledge when you’re trying a new ink or product!

Tip number 3: Use a smoothing screen or roller squeegee

For smoother prints, use a blank screen with a hard squeegee (or a roller squeegee). Hit the underbase with the squeegee directly after the ink is flashed. This helps stop fibrillation and unpleasantly textured “stucco” prints.

Flattening the ink’s surface with a roller or blank screen squeegee makes it softer, smoother, and thinner for the next layer of ink.

A roller squeegee is a great option for smoothing out your prints if you don’t want to deal with setting up a screen. They’re available from Action Engineering and most other major screen printing supply manufacturers for around $300.

Check out the difference between a print done without a roller squeegee (left) and with a roller squeegee (right):

Bonus tip: remove all of the lint and debris from your garments

Wrap a roller squeegee with a painter’s roller, then spray a small amount of spray tack onto the roller.

You can even use a plain painter’s roller and do this by hand, but it’s time consuming.

Roll the “sticky squeegee” over the garment to remove lint, dust, debris, and other annoying fuzzies that can cause fibrillation.

Other options for softer prints

Plastisol is just one type of screen printing ink. It’s the most common in North America (and typically the easiest to work with). However, there are other options that can yield even softer prints.

Adding adulterants to your screen printing ink – instead of using another type of ink – is always an option. Some shops love to “step on” their inks:

- Curable reducer can help make smoother prints by reducing ink viscosity (making it more liquid and free-flowing)

- Soft hand additive (like Triangle Soft Hand Base) is intended specifically to make plastisol smoother

Like any artisanal craft, screen printing isn’t about your gear. You can add all of the additives you want, but they’ll never replace good technique and understanding the variables that you can control.

Discharge and water based inks

Rather than try to put ink on top of the shirt, why not put ink directly into the fibers?

Discharge inks actually remove the dye in the fabric, allowing screen printers to use even less ink than they normally would need to. Some shops use a discharge ink as their underbase, then print plastisol on top of the discharge.

Others combine water based inks with discharge for a zero-hand print.

Remember: only 100% cotton t-shirts can be printed with discharge inks. For tri-blends and other shirts containing materials besides cotton, discharge is not an option.

Many water based inks have virtually zero hand, as well. However, they can be challenging to deal with on press (or simply unfamiliar).

Tip: looking for a way to get started with water based inks? Check out Matt Marcotte’s great introduction to water based inks, featuring some super helpful tips (like how to use a Reptile Fogger to keep water based inks wet while on press).

Sublimation – not screen printing, but another option

For things that can’t be screen printed – like all-over prints on differently shaped garments or certain types of athletic jerseys – custom sublimation may be your last resort.

Sublimation leaves no hand feel, but it is a manufacturing process instead of a printing process.

Most screen printing shops don’t offer sublimation in-house, but may know a subcontractor that can sublimate garments. The price rises significantly, but offers a unique feel and look compared to traditional screen printing.

Use DTG printing

If you’re not sure about DTG versus screen printing, you should know that DTG prints tend to have a very soft hand feel.

However, that comes with the tradeoff that DTG prints are less durable than screen prints.

DTG also isn’t appropriate for large volume orders – so it may not be a good fit for most screen printed orders.

BONUS: How to soften a screen printed t-shirt

If you’ve already printed a t-shirt and feel that the print isn’t soft enough – don’t panic.

A combination of the correct ink, the correct t-shirt, and the correct screens will make softer screen prints. If you’re struggling to get a soft print, check your screens (tension, thickness, mesh count). Then check your shirt’s fibers. Then check your ink. A lot of the problems people have getting a soft print can be traced back to one of those three things.

There is one major thing you can do to help soften a printed t-shirt – but we’ll give you a couple other tips as well.

Use your heat press

That’s right! Just use a heat press to press the shirts for a few seconds.

This will help soften the print, matte down any loose fibers, and generally make the shirt feel softer.

You can also use a heat press on your garments before you print to make the surface even better for printing.

Lower your off-contact

You can lower your off-contact on your press to help with a softer print. Learn more about the variables of screen printing.

Apply less ink

Use a softer stroke when you apply the ink.

Conclusion: soft prints aren’t an accident

Getting a smooth print isn’t magic. You can’t just add something to your ink. There’s more than we can cover here, but this is a great start.

You need to control all of the variables you can:

- Consider the shirt. Are you using a tightly woven shirt that is already a soft and smooth substrate for printing? Don’t try to save a few bucks by going with cheap t-shirts!

- Consider the machine. Is it printed by hand, or with a machine? A machine won’t always make a smooth print, but if you’re ordering hundreds of shirts you ensure consistency across the entire order.

- Consider the ink. What kind of ink are you using for the print? Plastisol ink doesn’t typically make soft prints!

- Consider the printer’s knowledge. How well does your screen printer know the variables that go into making a softer print? Is it something they offer, or did they bristle at the mention?

Always ask detailed questions to affect the outcome of your screen printing experience!

Saying “I want a soft print” isn’t enough. Dig into the details: quality shirts, quality equipment and screens, and the right ink.

Smooth hand plastisol screen prints are totally possible. You just need a little bit of knowledge, some time and a little practice to control the right variables.

0 Comments