So many screen printing shops have a hard time working with

It’s not that

What is plastisol?

Plastisol ink is just polyvinyl chloride (PVC, the same stuff common pipes are made of) and liquid plastic.

It’s the most common ink you’ll see in any screen printing shop. Why? Because it’s cheap, readily available, durable, and generally easy to work with.

Leave it on your screens with no problem. Leave it on a shelf forever and use it years later. Make sure it’s cured correctly, and it can last a hundred washes.

Sounds great, right? It mostly is.

Water based inks vs. plastisol

Why would screen printers want to invest time and energy into learning water based inks when plastisol is so easy, cheap, and permanent?

Because water based inks have some real advantages that make them appealing to customers and printers: they feel better, they’re better for the environment, and they unlock some powerful printing capabilities in your shop (plus they just look amazing).

The 6 benefits of screen printing with water based inks

Water based inks feel better

This is a simple truth: a good water based print feels better than a plastisol print.

While you can make a soft plastisol print, a water based print can often be nearly as soft as the t-shirt itself.

This means customers that love soft prints will almost always want water based inks.

Water based inks are (more) environmentally friendly

Compared to plastisol, some water based inks use fewer toxins and petroleum products.

While this isn’t always the case (and can be a common misconception), water based inks are generally considered better for the environment among industry experts.

The reasons include water based inks being made with fewer volatile and toxic chemicals, requiring less of a carbon footprint to produce, and producing less waste that goes to the drain compared to plastisol.

Water based inks are long-lasting

While plastisol tends to last for a hundred washes and then begin to fade, crinkle, and even chip off the garment (think of a really old t-shirt you might have) – water based inks can actually last much longer.

This is because water based inks can actually become part of the garment. Plastisol simply sits on top of the garment! Water based inks (since they’re water based) leave behind pigments.

These pigments can become part of the fabric itself and last as long as the garment lasts.

Water based inks allow higher detail

While you can achieve high detail prints with plastisol, water based inks can be made so thin that they’re able to be used on extremely high mesh counts.

This means shops like Night Owls Print and Printed Threads, which print high-detail water based art, can achieve photorealistic results and microscopic details.

Water based inks are breathable

If you’ve ever worn a t-shirt with a large plastisol print, you know that plastisol ink simply doesn’t “breathe”.

Most water based inks don’t feel like this. Water based inks typically able to allow air to pass through, since the pigments are embedded within the fibers of the garment.

Water based inks don’t sacrifice quality or color

While Pantone matching water based inks was a problem in the past, it’s now something that highly technical shops can do effortlessly.

There’s some apprehension about water based inks: won’t they be less vibrant than plastisol? The answer to that question is no. Water based inks do not sacrifice quality or color.

Which water based inks are best?

Everyone in the industry likes to fight over which screen printing ink is best.

It’s really like asking which pizza is best. (It’s Pequod’s, though. I may have to watch my back for a while.)

The truth is very simple.

The best

- It works on your shop’s press.

- You have a helpful supplier for it.

If the ink comes from a supplier you trust and it works for you, then it’s good ink. Don’t worry about the other noise.

To find the

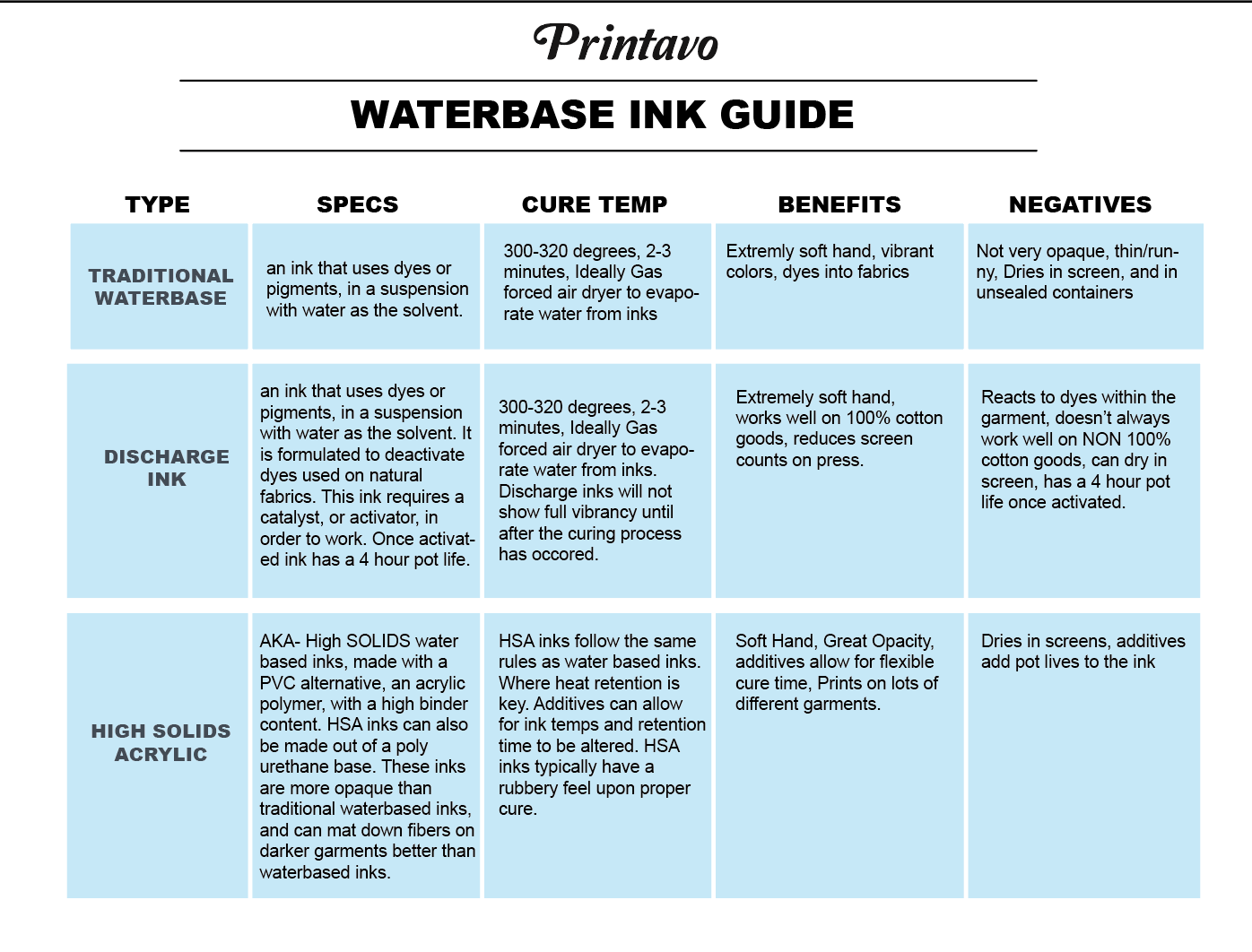

What types of water based inks are there?

That tends to throw people off!

Traditional

So here’s a breakdown of the different

Traditional water based ink

With a runny, almost liquid consistency, water based ink alters the garment’s fibers. It has a tremendously soft hand feel. Because of the high water content of the ink, it must stay wet during printing.

Discharge ink

A fluid, but slightly more viscous, consistency than traditional water based ink. Discharge inks are a powerful tool. They work by using an activator to bleach out the existing colors on the shirt. This means you can reliably print vibrant colors even on dark garments by using discharge inks as an underbase layer.

Acrylic ink

With acrylic particles added, this type of water based ink has a thicker, plastisol-like consistency. It does not actually alter the fibers of the garment. Acrylic inks come from the consumer need for a plastisol-like water based ink. It doesn’t need quite as careful management on the screen as other water based inks.

Acrylic inks are becoming more popular thanks to the growth of digital hybrid printing (also known as “the giant new machines that cost as much as a small house”). Lots of digital printing machines print on top of a tradition screen printed

Why do you want to screen print with water based inks?

Plastisol is incredibly easy to use. It won’t dry up sitting on a screen and will never puddle. So why should you switch to water based ink?

- It’s marketable as an environmentally friendly product. Use water based inks to appeal to customers that are concerned with the environment.

- It’s popular in markets outside of North America. In Asia, Europe and most global markets, water based inks are the standard.

- They feel amazing. Compare any water based ink to any plastisol print to see what we mean.

- They make your shop more capable. With higher detail, better hand feel, and a broader range of image capabilities, water based inks make your shop better at meeting any customer’s goal.

- They’re long lasting. Water based inks rarely wash off or have other problems typical to plastisol.

View this post on Instagram

What should you do when water based inks dry in the screen?

This is simply the most common issue with

In the fine art world, the simplest solution is to add a retarder: glycerine would be added to

There are three solutions for slowing down the drying process with your

Use helpful chemicals to slow down drying

Check with your ink manufacturer to see what kind of

A

Get a reptile fogger to keep your ink wet

I bet you didn’t think you’d need a reptile fogger.

Here’s a brilliant hack to keep your

Use a reptile fogger to keep your ink wet!

These cost about $50 when they’re new, and you get a

Here’s an example:

View this post on Instagram

Be sure to use distilled water in your fogger to keep contaminants out!

Use lube

All jokes aside, throughout the years I’ve learned that coating your screens with the ink manufacturer’s recommended lubricant is critical.

Before any

By penetrating the entire mesh with lubricant, you slow down drying and make printing much smoother.

What should you do when water based inks break down your screens?

This is the other big problem shops run into when they start printing with

Emulsion formulation is key to keeping your screens from breaking down. Emulsions have different solid content levels, different levels of durability when exposed to different inks, different exposure properties and so on. So how do you choose?

View this post on Instagram

Virtually every supplier for garment decorators has a good emulsion that you can use. You may have to alter your emulsions to get the toughness you’ll need.

When in doubt, go with Diazo for the best durability when screen printing with

Proper exposure leads to optimum cross-linking. Cross-linking is when the semi-solids in your emulsion become a solid through reaction with UV light. Take the time and invest in getting

- Get an exposure calculator. This is a low-cost investment and will pay for itself many times over.

- Consider the exposure unit. There’s some debate about whether LED exposure units will create proper cross-linking like mercury vapor bulbs do. I’ll leave that to the real scientists. But you may need to experiment with different emulsions to get durable results when you switch light sources.

Always post expose.

Here, I’m going to say it louder: ALWAYS POST EXPOSE!

This is a super simple step that so many shops overlook or think isn’t necessary.

After you’ve exposed your screen and it’s dried off, take your screen and expose it to more light. Turn off your exposure unit’s vacuum function and expose the screen ink-side down (opposite of how you normally expose screens). You can even just expose it to sunlight for a minute or so.

The point is to further harden the ink-side of the screen. This is a very easy way to improve the durability of your screens.

Three basic tips for water based inks

- The less water you have in your ink, the harder it is to work with.

Water based ink has lots of water in it (seems obvious, right?). But as the ink loses water, it becomes stubborn and hard to work with. - Think about

water based ink likeit’s blood. If you get a small cut, it scabs up quickly. But a larger wound has flowing blood and won’t immediately scab up or dry out. - Keep it moist, keep it moving. You’ve got to manage

water based inks so they don’t dry out and give you issues.

View this post on Instagram

Conclusion

Water based inks are an opportunity to offer your customers the longest-lasting and softest custom shirt possible. It’s a screen printing technique that adds value and impresses clients.

Too many screen printing businesses are afraid to experiment with new techniques – but

Now that you know where to start, and are armed with some practical tips, go find out how you can utilize

Matt Marcotte is part of Printavo’s Customer Success team. With more than a decade of high-volume production, sales across the midwest, and his own personal shop on the side, Matt’s insights into the industry and process of screen printing are invaluable.

0 Comments