There’s one sure-fire way to do it: do a bad job moving your shop.

A lot of us started printing in our bedrooms, garages, and basements.

As time goes on, a squeaky-clean warehouse with tons of space starts to seem like a great idea. No more ink smell at home. No more annoyed neighbors. Tons of space to spread out and put that giant auto press you’ve dreamt about.

But moving a screen printing shop isn’t easy.

Here are a few questions to ask yourself:

- Do you have the time and energy to move?

- Will your business plan suffer if you move?

- Can you afford to move now?

- Can you afford to wait to move now?

Move too soon and your business suffers. Don’t move and you might stay in your garage forever.

So how do you decide when it’s time to move your screen printing shop? Consider the practical case (finances) and the business case (strategy).

I Moved My Screen Print Shop Successfully

In 2014, I didn’t know much about screen printing. I’d just bought into Campus Ink as a 24-year-old.

So why would you want to hear from me? Campus Ink started as Campus Sportswear in 1947. They printed on the second floor of a building with just two thousand square feet of space ever since. In 2020, we opened a new retail location. The 12,000 square foot production facility we added is pretty nice, too.

Campus Ink has a lot to be thankful for. Its success came from its proximity to the University of Illinois Urbana-Champaign. At the time, it was owned by two 55-year-olds. They are hardened veterans of the screen print industry. I daydreamed about modernizing the business while I learned the basics during a challenging year of climbing the learning curve.

Once I’d earned their trust, we took our workflow into the digital age. Because of our ability to build amazing customer relationships and consistently deliver great products, we outgrew our old space. I wanted to move as soon as I bought in: buy the fancy equipment, get the nicest warehouse, take out big loans and just go from there. Luckily, the wisdom of experience told my co-owners to wait.

Good advice likely saved our business from my youthful desire to move fast and break things:

Buy in cash, don’t take on debt, grow until you absolutely have to move.

When Should I Move My Screen Printing Business?: Want vs. Need

Before you move your shop, you should explore every option. The minimum viable move may be to run another shift, hire help to utilize the space you already have better, or outsourcing work to contract printers.

If you’re anything like me, here’s how you imagine moving your business:

- Pick out the most perfect space so you can do the absolute best & most work.

- Figure out if you can (at least mostly) afford it.

- Move, then grow the business from there.

That sounds great, right?

Pick out a big space for everything you think you’ll need, and figure out how to grow the business once you’re in. After all, with all that new space you’ll have no problem making even better products at a higher speed!

This is a recipe for disaster.

The safest strategy for the long-term health of your business is the minimum viable move.

So what does a minimum viable move look like? Chief Executive describes it as “making just enough of an organizational change to determine whether or not the move will be valuable to your business.”

Before you move, explore every other option.

Moving is expensive.

Surprise expenses are guaranteed. Lost production time is inevitable. Sometimes, you could lose customers. You may even lose employees.

The best way to move a screen printing shop is something like this list:

- Grow the printing business until you see a steady upward trajectory in sales.

- Do the most with equipment and employees you have.

- Do the math. Carefully figure out if you can afford to relocate.

- Know your needs. Search for the space that fits your exact needs. Not your exact wants.

- Act fast. Move deliberately.

Does Your Screen Printing Business Need More Room?

A lot of screen printers think that their business will benefit from having more room. But this isn’t the case.

Do you think that a warehouse will make it easier to run your business?

Or does moving your screen printing business mean that you’ll be able to perform new print techniques, serve new customers, and make more money?

There should be an operational need to move your business.

A big warehouse is not a screen printing business strategy. “Grow into it” isn’t a plan. Image courtesy @redwallprints

Do you really need to move your print shop?

Do you agree with these statements:

- I know exactly what I’d do with the new space, and I can name the needs it fulfills for my business.

- I’m certain I’m already using my current space to its fullest extent.

- I’m having trouble growing because of space limitations, not because of business or marketing efforts.

- My business is sustainable, with sales projections trending upwards.

Unless you agree with all of them, don’t move your shop.

“More room” can introduce more maintenance and overhead into your print shop. The grass is not always greener on the other side!

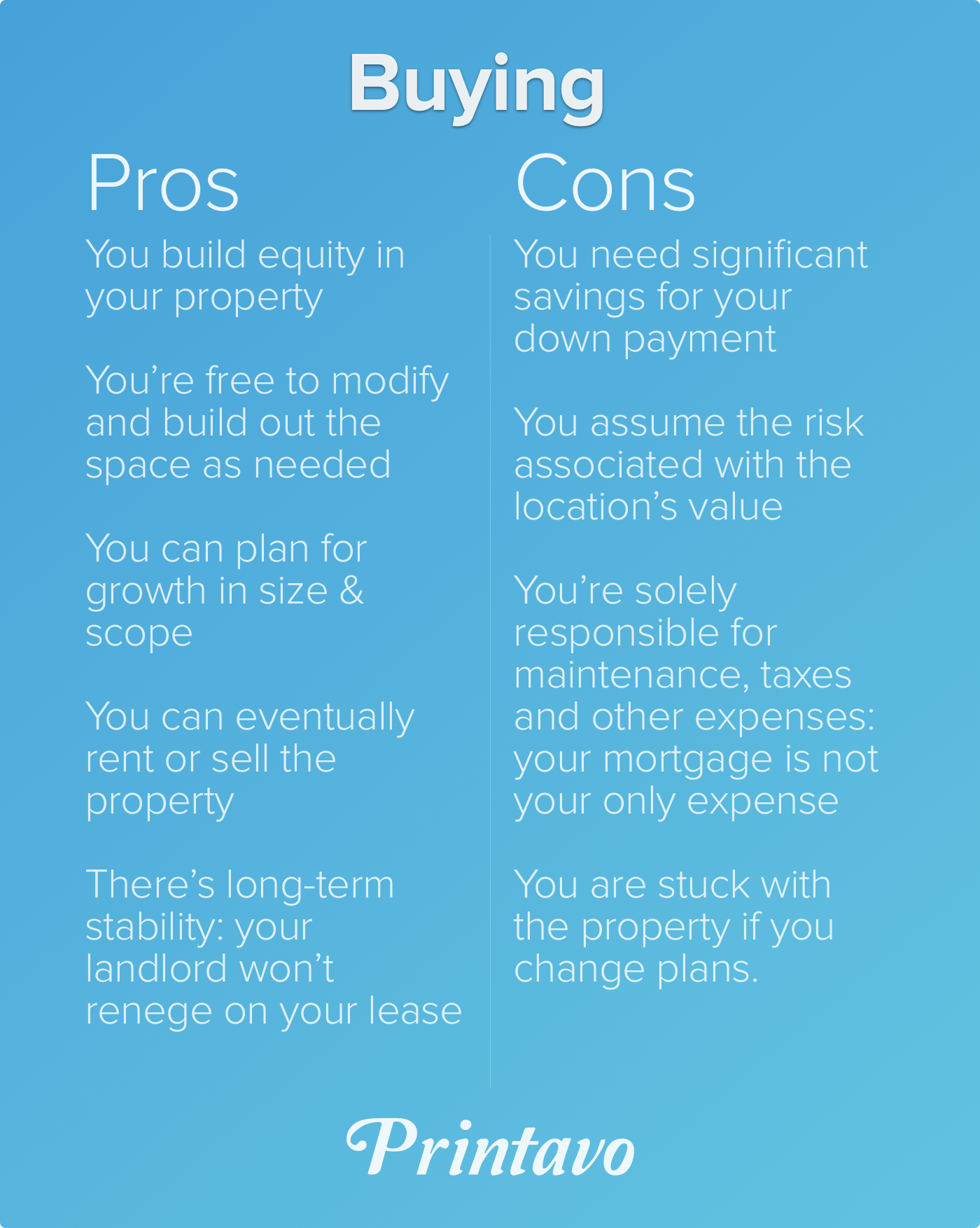

Renting vs. Buying Your Building As A Print Shop

You’ve run the numbers, you’ve got a solid plan, and a thriving business ready to move.

So should print shops buy or rent their building?

Buying Your Print Shop

Buying the building your print shop uses can be great! But it’s hard.

Paying your own mortgage (instead of a landlord’s) is a big upside. You may build equity in the building.

But there are real risks associated with buying property: it’s not just the mortgage payments that you need to plan for.

Renting Your Print Shop

Renting is affordable and relatively low-risk compared to buying your building. On one hand, you need a reliable landlord that will help you with any repairs. They have some control over your business, since they own the space that you work in.

On the other hand, it’s less expensive to rent your print shop than to buy a building. If you don’t have a large amount of savings, you’ll have to start by renting. It’s also great short-to-medium term option for print shops.

Carefully evaluate exactly how much space you’ll need.

Many print shop owners say that their business quickly outgrows the space that they have.

If there’s uncertainty about your space requirements, renting is your best short-term option.

If you rent, you won’t pay too much for space you’re not using – or worse, lock yourself into a space that’s too small.

I can’t tell you whether to rent or buy. That’s a choice you have to make.

Consider your budget, what your goals are, and how comfortable with risk you are.

But if you do rent, there are plenty of resources for determining what your shop can afford.

Choosing the Right Space: What to Know Before You Move

Before you move your screen printing business, you need to know:

- Your floor plan.

- Your business plan.

- Electricity and plumbing requirements.

- How to safely move your equipment.

Each print shop is different. The requirements for your unique business are part of choosing the right space for your print shop.

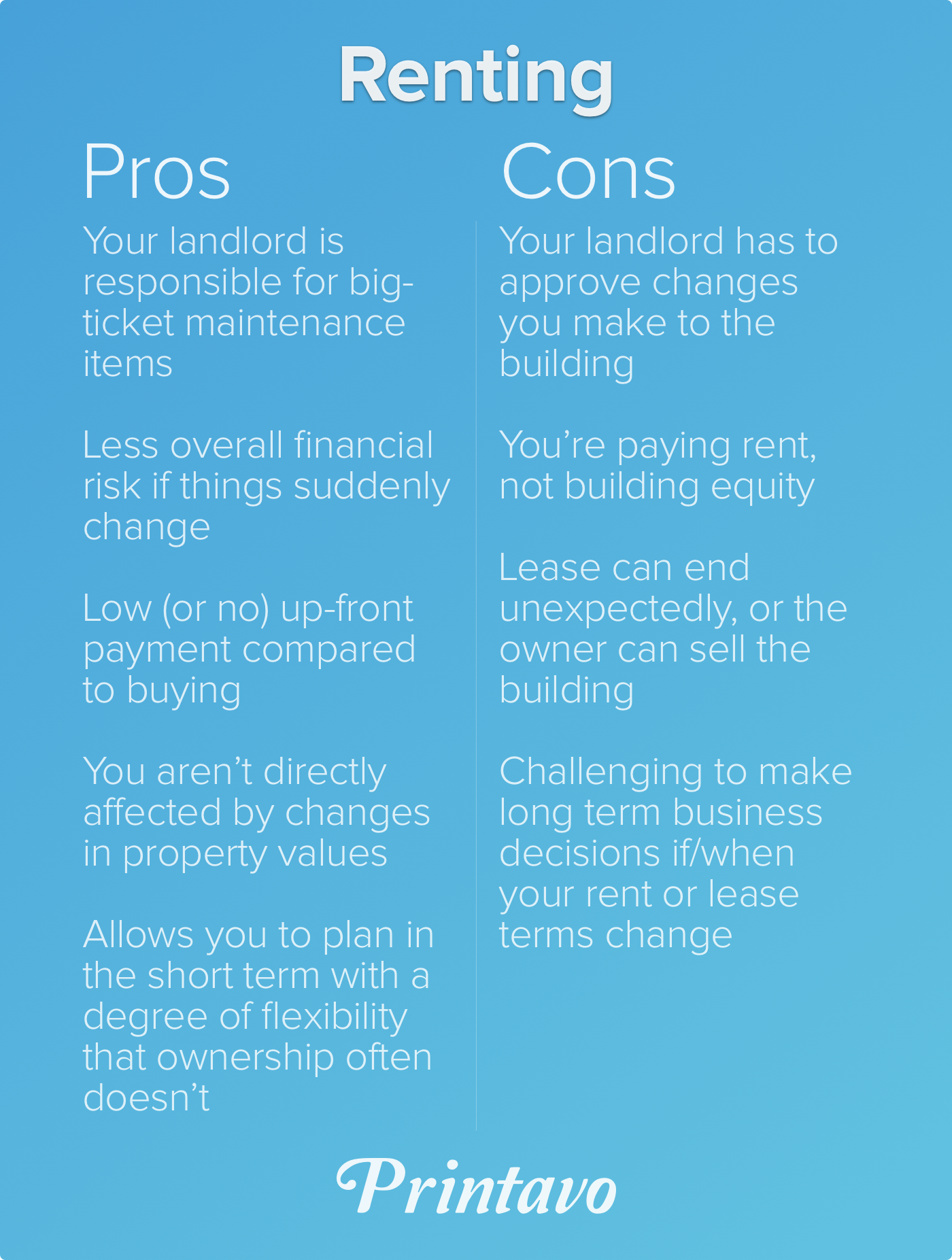

Your Floor Plan

The easiest way to plan your space is to get out the pen & paper and start sketching up a floorplan.

If you know the measurements of your equipment, you can get extremely specific about space requirements.

Laying out a new shop doesn’t have to be difficult. Image from Fink’s Graphic Design.

Here’s an example for how print shop square footage is challenging to plan for.

If you do screen printing and embroidery, you’ll have different space requirements in your shop.

Most automatic screen printing presses need 3,500 square feet for one press and all of the accompanying equipment required.

Embroidery machines can fit into 500 square feet or less (for a 6 head machine).

The measurements of the equipment you’re intending to purchase are good guides for estimating floor space. You can find these measurements from your sales rep, or even directly on the equipment’s product page.

Dimensions for the different ROQ YOU automatic presses.

You can’t just cram equipment into your building and call it a day.

Remember to add working space. 5 and 10 feet (1.5-3 meters) of “clear zones” around your equipment can create valuable working space around the machine.

These clear zones create space for staging t-shirts and other supplies.

What Your Business Plan Means for Your Space

If you’re adding several auto presses and taking on thousands of dollars in debt, you should know how exactly many more square feet you need. Then you should know how many jobs you need to sell to be able to pay for it all!

Finally, you have to know whether building equity in a building is your business goal – or building your print business!

This may seem obvious, but it’s something that often gets filed under “figure it out later.”

If you plan to growing into different types of presses, embroidery machines, DTG printers, and so on as you grow your business, then you should search for the space that accommodates your business plan. Get specific.

For example, check that your business plan asks important questions about your shop.

- Will your business outgrow its current equipment if your strategy works?

- Will you need to buy more equipment?

- Will you have to replace old equipment?

- Will you need to purchase a new conveyor dryer for screen printing larger quantities?

- Did you plan for more space for incoming and outgoing goods?

Search carefully for the space that fulfills your needs. Your equipment, print shop workflow, and even employees are all part of equation.

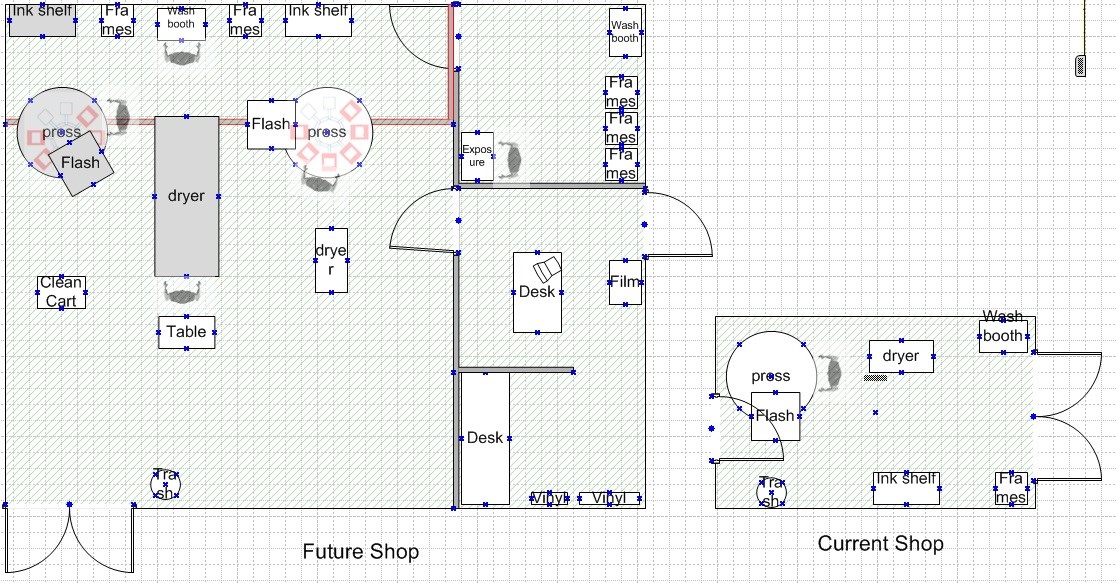

Electricity & Plumbing Requirements For Screen Print Shops

Do your due diligence about electricity and plumbing. Print shops have specific needs when it comes to plumbing (for waste disposal and screen washing) and electricity (for high-energy dryers and flash units).

Ask an expert for help if you’re not 100% sure about what you need.

The wrong electric hook-ups will ruin your move.

You must have “3-phase power” in your screen print shop to be able to use things like:

- Automatic presses

- Conveyor dryers

- Flash units

- Exposure units

- HVAC systems

- Computers and other accessories

Garment decoration equipment needs lots of energy.

Most commercial spaces have 3-phase power.

If you’re in a rural area or moving into an older building, ensure that there’s existing 3-phase power.

Many light industrial buildings have existing “power drops.” Outlets must be in the right places. Budget for an electrician to add new breakers or perform other modifications before you move in to the building.

Installing 3-phase power in a building is very expensive. That’s why you want be 100% sure you have the right electricity before you move your print shop.

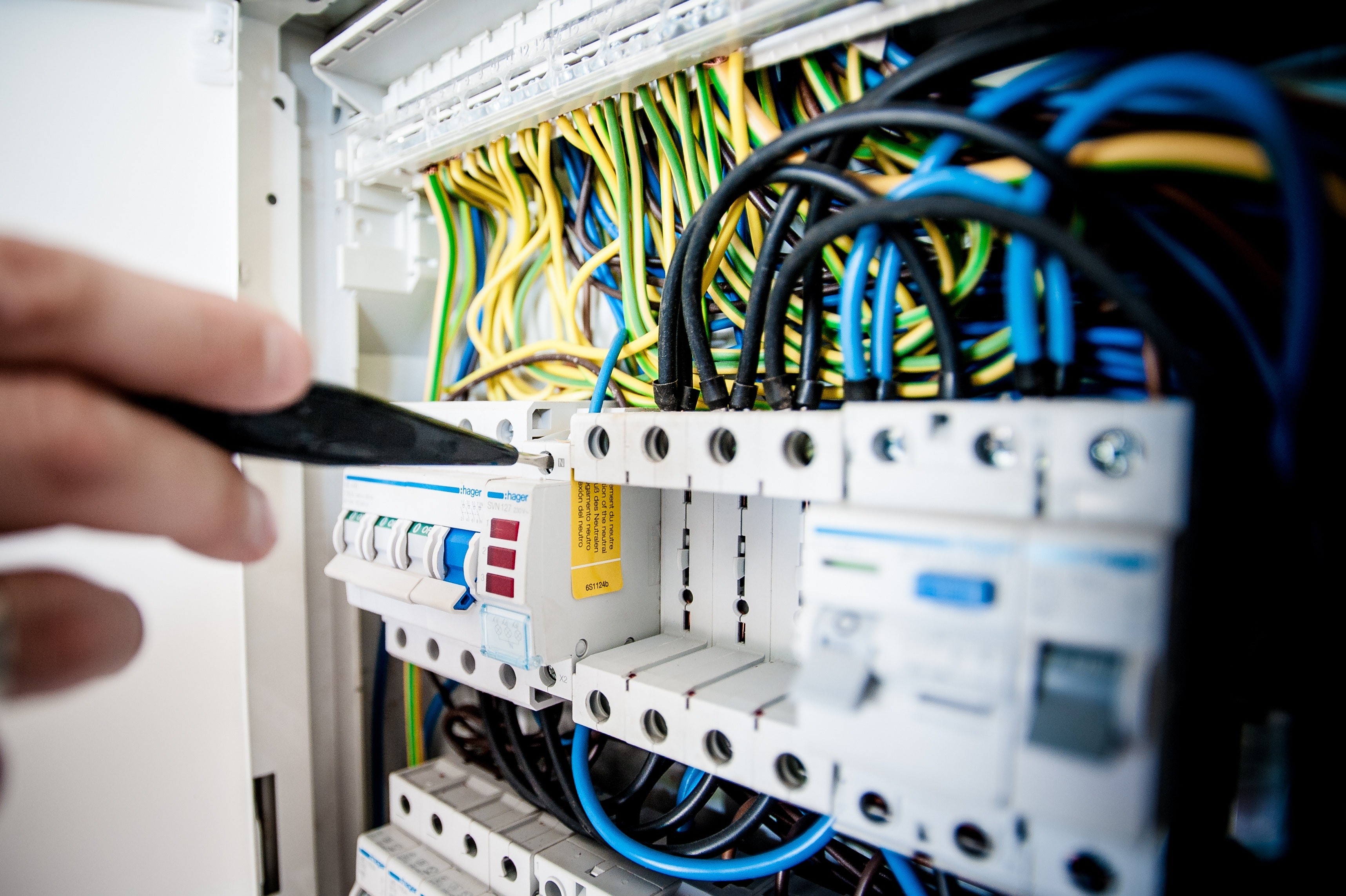

For plumbing, carefully consider whether the building has:

- Water in the right location: Faucets, sinks, and water sources should be in the right place. Workers shouldn’t travel across the shop repeatedly to access water.

- Suitable plumbing updates: New plumbing and fixtures are very expensive.

- Direct sewer access: Do not fill a septic tank with ink, emulsion, and other waste from washing and coating screens. Direct sewer access is required.

Good plumbing is how you can protect the health and well-being of your employees, your local community, and the environment.

Read and understand the MSDS requirements and local regulations for every chemical involved in your process. Safe handling and disposal are essential.

Many chemicals used in the screen printing industry are drain safe. A properly outfitted filtration system for your washout booth reduces the risk that you’ll damage your plumbing or violate the law.

Uncured Plastisol ink contains unpolymerized vinyl chloride, a serious toxin implicated in a variety of chronic illnesses. The correct plumbing regime protects the health of your employees, community and local water table – and protects your plumbing against expensive clogs!

Resources for Moving Your Print Business

As always: do your research.

There’s a wealth of topics about business relocation that go deeper.

You should always consult with a professional if you’re uncertain – the small cost for a business consultation far outweighs the damage that a poorly planned move can do to you & the employees you’re responsible for.

- Leverage this checklist for moving your business. It’s full of practical considerations that I didn’t get to cover here.

- See if you can save money on your move with some simple moving organization tips.

- Consider these 13 things before you move.

0 Comments