When should you buy an automatic screen printing press?

There are five common signs that your business is ready for an automatic screen printing press.

We’ve seen these signs pop up again and again among the Print Hustlers community.

Though your shop could have a lot of reasons for needing an automatic press – from wanting to print faster to needing the consistency of an automatic press – most of the signs are actually signs that your business is ready to grow.

One easy way you start assessing if it’s time to go automatic is by taking this quick quiz from ROQ. The Auto Ready Score helps dial in if your business is in a position to invest in an automatic press and even helps you drill down what kind of press you should buy.

#1: Fatigue. Your body hurts from printing

Every manual screen printer knows how taxing manual screen printing is on the body.

Loading and unloading shirts is difficult enough – but pulling the squeegee (particularly on designs that have more than one color) for hours at a time can become unbearable.

There are several signs that you need an automatic press for your health:

- You feel pain when you go to print.

- You’re constantly fatigued from printing.

- You are developing early symptoms of carpal tunnel syndrome.

- You dread printing more shirts.

When your body can’t keep up with the demands of the business, it’s time to think about making the jump to an automatic screen printing press.

#2: Volume. You turn down (or can’t get) orders

For a small business, a single big order can be a make-or-break moment. Would you know what to do if a marathon asked you to print 10,000 pieces? (We’d suggest using a contract printer to help you rather than suffering through 10,000 manual prints, by the way.)

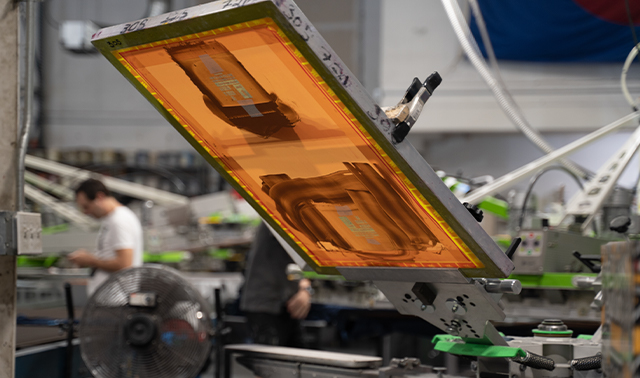

Even large shops use manual presses for small orders and test prints. Photo courtesy ROQ.US.

Maybe you get several 200-piece orders in a row and have to turn down a 600-piece order just to be able to meet your deadlines. You wind up sending business to the shop down the road without meaning to.

When you’re pulling all-nighters and wearing yourself out just dragging a squeegee and loading shirts, you’re probably not putting your best foot forward when you’re doing sales, marketing, art, or whatever high-value activity you specialize in.

Check out how Barrel Maker used a 60,000 shirt order as an opportunity to grow their business.

Should you buy an automatic press right now?

Remember: screen printing equipment does not generate demand. This means that you shouldn’t expect more orders to come flowing in just because you’ve got a brand-new shiny press.

A good strategy is to have three times the monthly payment for your first automatic in orders coming through your shop every month before you take the leap. But your appetite for risk may differ!

#3: Time. You want more time to grow your business

With an automatic press, you don’t need to meticulously schedule your day!

Screen printers can expect to knock out 300 prints per hour with an automatic press – at a leisurely and careful pace. The time savings are huge.

When you’re screen printing at this volume, an automatic press is crucial.

Three 72-piece orders on a manual press, printing at 100 pieces per hour and allowing for around an hour of setup and downtime, would take a little less than three hours of printing.

Three 72-piece orders on an automatic press, even allowing for an hour of setup and downtime, would take less than two hours.

As the orders get larger and larger, the time spent printing on an automatic press adds up.

You can use this time to do revenue-generating activities: for example, pitching your services to local businesses or hiring great artists to help you make incredible designs.

#4: Technique. You want to make better prints

When you find that manual printing is no longer able to keep up with the art, styles, colors, or jobs that you want to print – it’s probably time to find a great contract printer or carefully think through the economics of purchasing an automatic press.

Automatic screen printing presses are far more reliable than manual screen printing presses.

They can print at specified pressures and angles with far more precision than any human being. You can get repeatable, reliable results by carefully documenting the variables on your automatic press – making complex images and repeat orders a snap.

Additionally, you can use much higher screen mesh counts on an automatic press. This means your images are much more detailed, opening up a range of possibilities for designs and images you can print.

Refining and standardizing your printing technique helps maintain consistency across all your orders.

You can also purchase automatic screen printing presses designed to print far more colors than typical manual presses – for example, Riley Hopkins sells an 8-color, 6-station manual press (The Riley Hopkins 300), but if your demand and output calls for an automatic, ROQ.US sells an automatic press (the ROQ YOU) that offers up to 20 colors and can print as much as 1,000 garments an hour.

If you’re simply looking to make better prints, provide more colors, and know you can count on your quality no matter who’s pulling the squeegee – an automatic press is a quick pathway to success.

Continued education is also a great way to refine your process. Places like MADE LAB offer comprehensive classes in automation so you can get a better grasp on how to run an automatic press.

#5: Investment. You’re planning for the future

“Begin with the end in mind,” Mark Coudray reminds us.

What is your goal?

For example, do you want to build a business you can sell? Do you want to leave it to your family and children? Or maybe you simply want to grow it as large as you can? Maybe you have other ambitions – like working with whatever clients you’d like.

An automatic press is the first step in building an automated print shop.

The speed and sheer quality that an automatic press brings to the table is unrivaled by any other type of equipment. When you’re planning for the next 5+ years instead of just thinking about the next job, an automatic press begins to make a lot of sense.

The growth flywheel strategy and automatic presses

No matter what your goal is, investing in state-of-the-art software and technology for screen printing is a tremendous operational advantage.

When you have built the clientele to sustain the payments (or built up savings to buy the machine outright), you build a flywheel for growth: you collect better orders, the orders help your customers grow, and they place even better orders with you.

This pattern isn’t a pipe dream – we’ve seen it again and again: an automatic press can unlock rapid growth given the right situation and right work ethic.

More articles and help

When you’re ready to jump into an automatic press, read our article: Buying an Automatic Screen Printing Press? What to Know, What You Really Need, and How Much It Costs.

If you’ve got concerns about upgrading to an automatic press, check out ROQ’s free downloadable e-book on the fears that come with jumping into automation.

They’ve also got a great resource on how to handle your automatic installation.

Learn which automatic screen printing press you should buy from Printavo’s Matt Marcotte.

Cruise through our FAQ for screen printing machines, which covers the most common questions about purchasing and evaluating screen printing machines.

Before you add a second automatic press, think about buying this piece of important screen printing equipment first.

If you need a reputable company to get you started in your search for a press, contact ROQ.US. They can discuss your goals and help you find an automatic press that fits your business’s needs.

0 Comments